Cable slicing device

A technology of slicing device and cable, which is applied in measurement devices, metal processing, instruments, etc., can solve the problems of inability to guarantee the accuracy of test results and uncertainty of detection, and achieve the effect of reducing labor intensity, improving efficiency and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

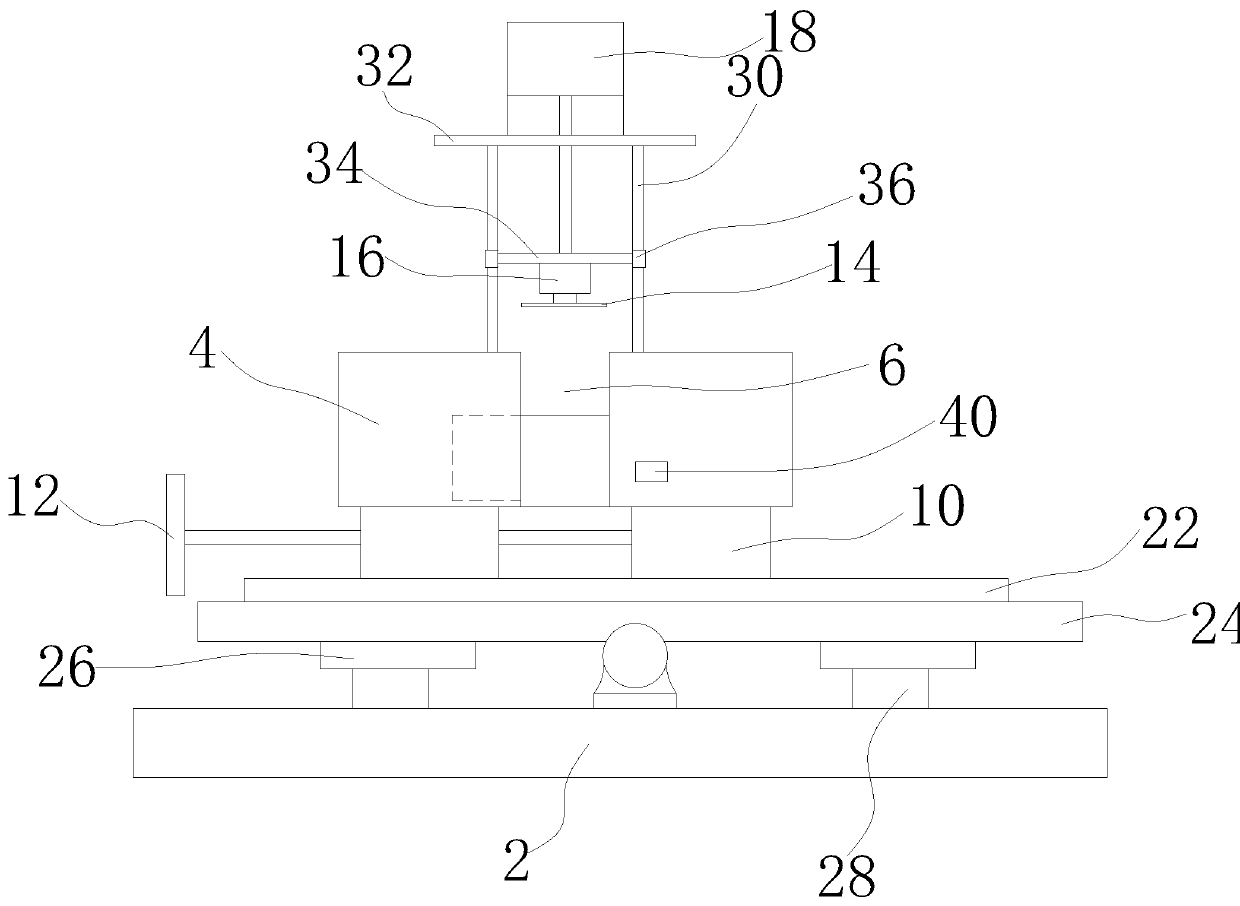

[0021] The invention discloses a cable slicing device, which replaces the traditional manual operation by mechanical means to cut the cable along the cross-sectional direction of the cable, and completes the mechanical slicing and sample preparation of the cable. The preferred structure of the technical solution of this embodiment is as follows:

[0022] refer to Figure 1~3 As shown, it includes a machine platform 2, a cable fixing mechanism and a cable slicing mechanism all installed on the above machine platform 2;

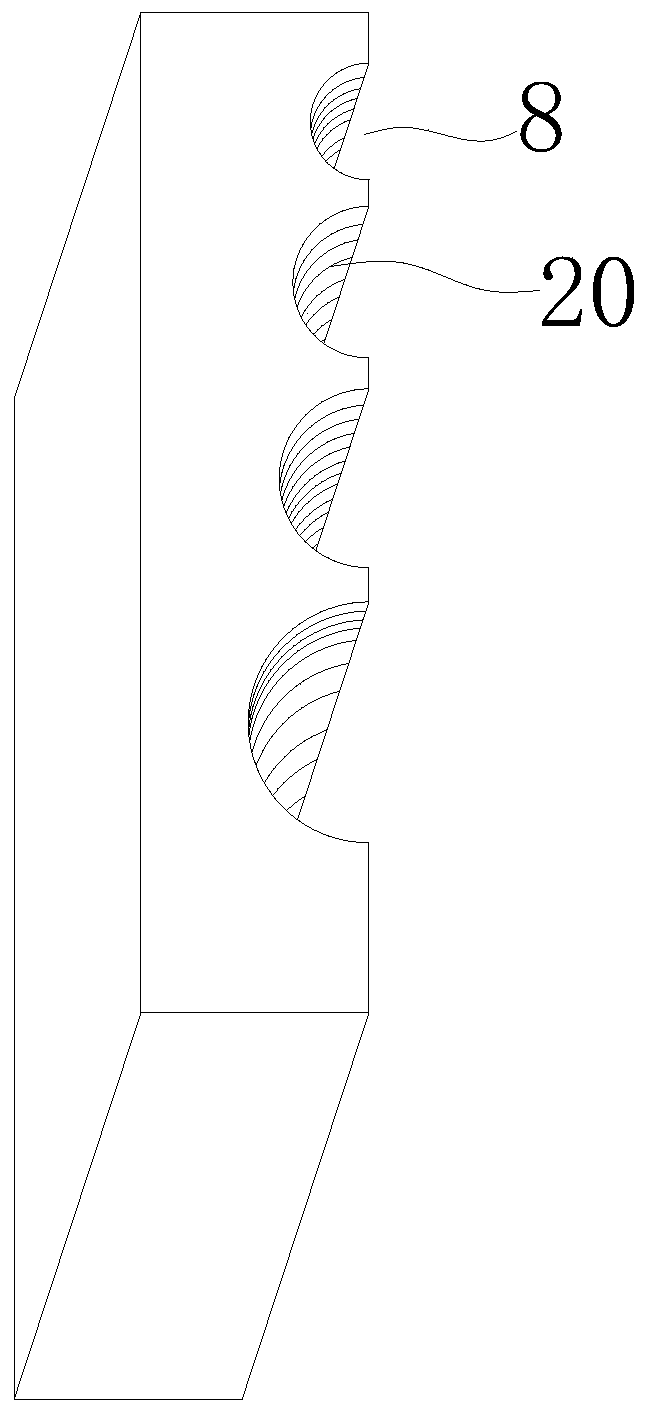

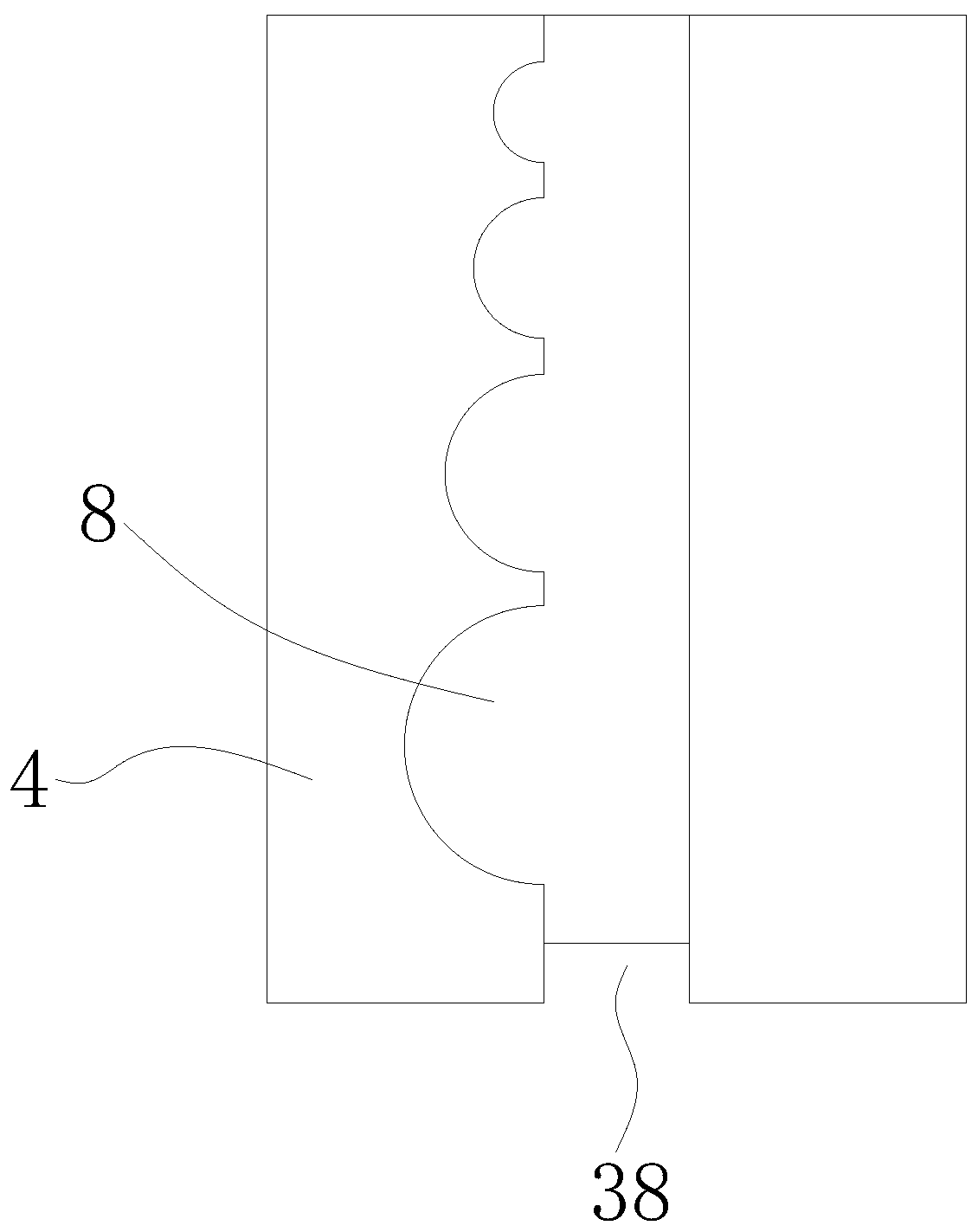

[0023] Such as Figure 1~3 As shown, the above-mentioned cable fixing mechanism includes a pair of cable clamps 4 opposite to each other. There is a cable groove 6 between the above-mentioned pair of cable clamps 4 for placing the cable to be sliced. The end of the cable groove 6 is provided with a tool avoidance part 38; one of the above-mentioned cable clamps 4 is provided with a profiling cable clamping channel 8; The cross-section of the cable channel 8 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com