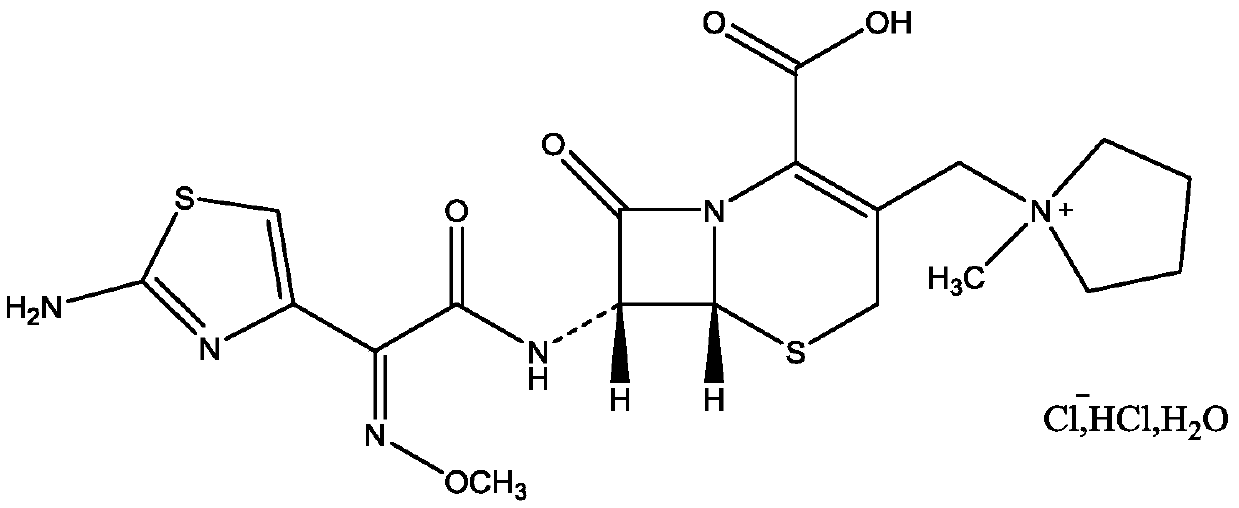

A kind of purification method of cefepime hydrochloride

A technology of cefepime hydrochloride and purification method, which is applied in the direction of organic chemistry, can solve the problems of complex operation, high operation and maintenance costs, and large equipment investment, and achieve the effects of simplifying operation steps, saving investment in decolorization equipment, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method comprises the following steps:

[0029] A. dissolving the cefepime hydrochloride crude product in a mixed solution of water and an organic solvent, stirring and dissolving at 20 to 30° C. to obtain a cefepime hydrochloride crude product solution;

[0030] The ratio of the volume in milliliters of the mixed solution of water and the organic solvent to the mass of the cefepime hydrochloride crude product in grams is 2.5 to 4.5:1; the volume ratio of water and the organic solvent in the mixed solution of the water and the organic solvent is 1:1.5 to 2.5, The organic solvent is any one or a combination of acetone, acetonitrile or N,N-dimethylformamide;

[0031] B. adjust the pH of the cefepime hydrochloride crude product solution to 4.0~5.0;

[0032] The solution used to adjust the pH is any one of dipropylamine, diethylamine or triethylamine;

[0033] C. Add a dispersant, adjust the pH to 0.8-1.0 with hydrochloric acid solution at a temperature of ...

Embodiment 1

[0039] The invention discloses a method for purifying cefepime hydrochloride. The crude product of cefepime hydrochloride is used as a raw material, the pH of the solution solution of the crude product of cefepime hydrochloride is adjusted, a dispersant is added, and cefepime hydrochloride is obtained after isoelectric point crystallization.

[0040] The preparation method comprises the following steps:

[0041] A. Get 20g of cefepime hydrochloride crude product, add in the mixed solution of 20mL purified water and 30mL acetonitrile, control temperature 30 ℃, stir until dissolving clear, obtain cefepime hydrochloride crude product solution;

[0042] B. adding diethylamine to adjust the pH of the cefepime hydrochloride crude product solution to 5.0;

[0043] C. Add 100mL of a mixture of ethyl acetate and acetone with a volume ratio of 1:1.5, under temperature control at 25°C, add hydrochloric acid solution dropwise to adjust the pH to 0.8, and grow crystals at 20°C for 0.5h;

...

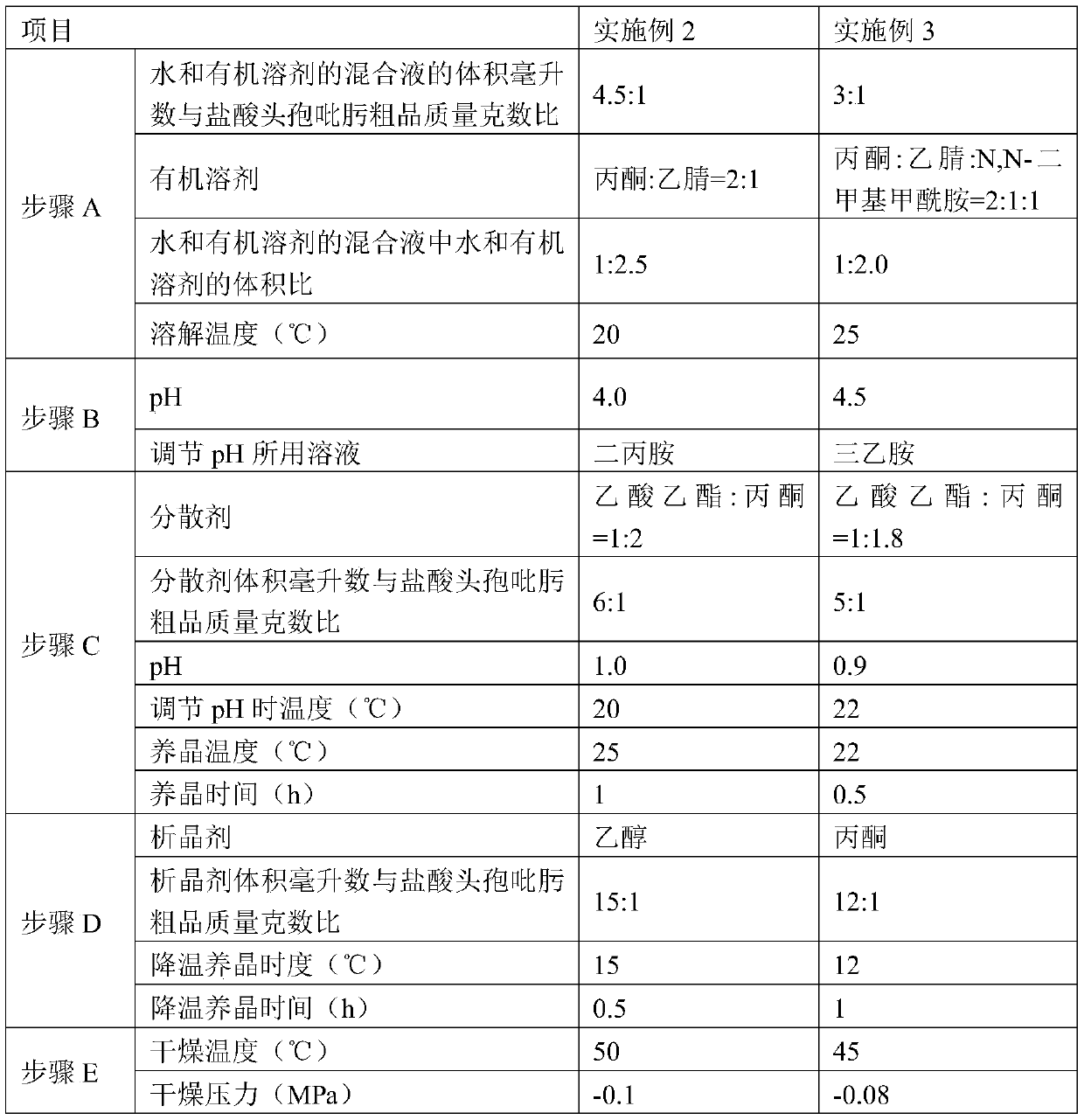

Embodiment 2~3

[0047] Embodiments 2-3 have the same production process steps as in Embodiment 1, the difference is the selection of process parameters, as shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com