A screw nut transmission mechanism, a self-adjusting telescopic mechanism and a photographic mechanical arm

A technology of screw nut and telescopic mechanism, which is applied in the field of screw nut transmission mechanism, self-adjusting telescopic mechanism and photographic mechanical arm, which can solve problems such as inconvenience, and achieve the effects of increasing the maximum length, driving force output balance, and increasing the variable length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

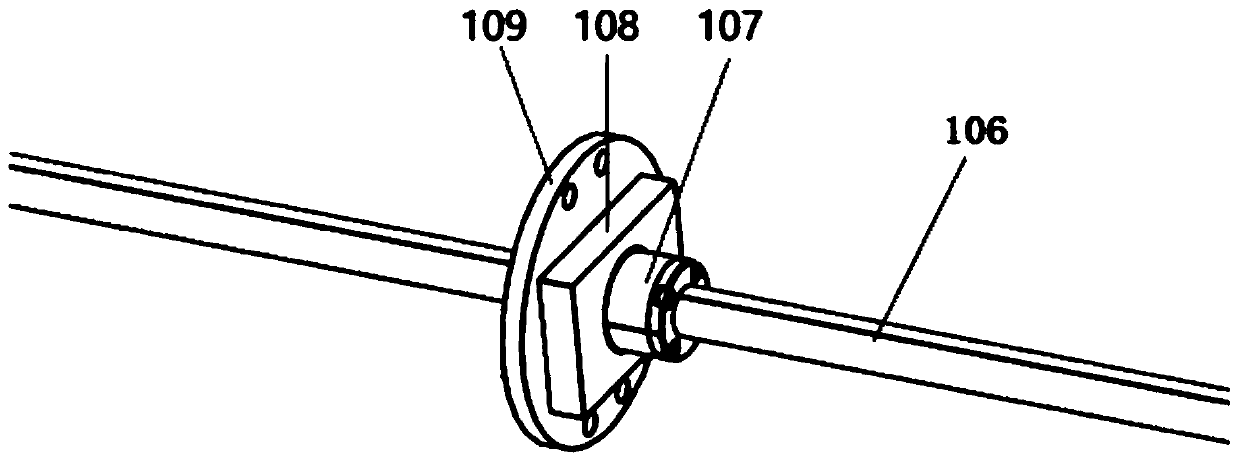

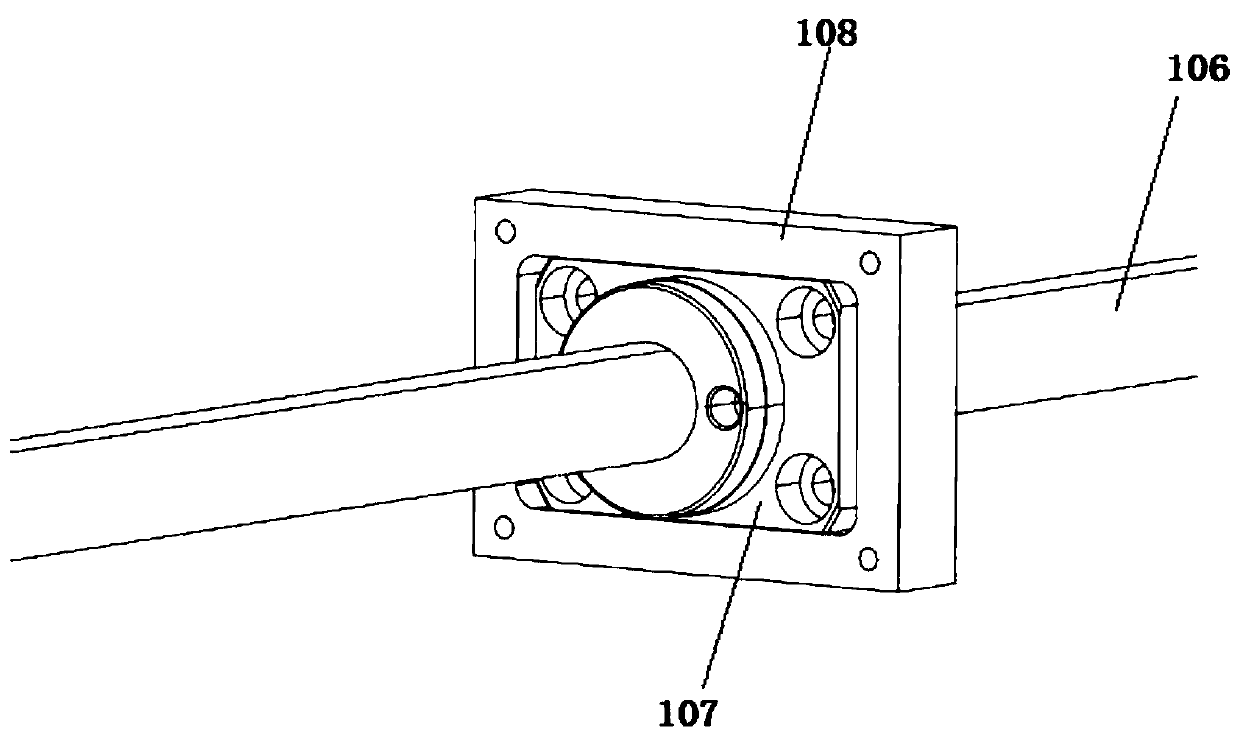

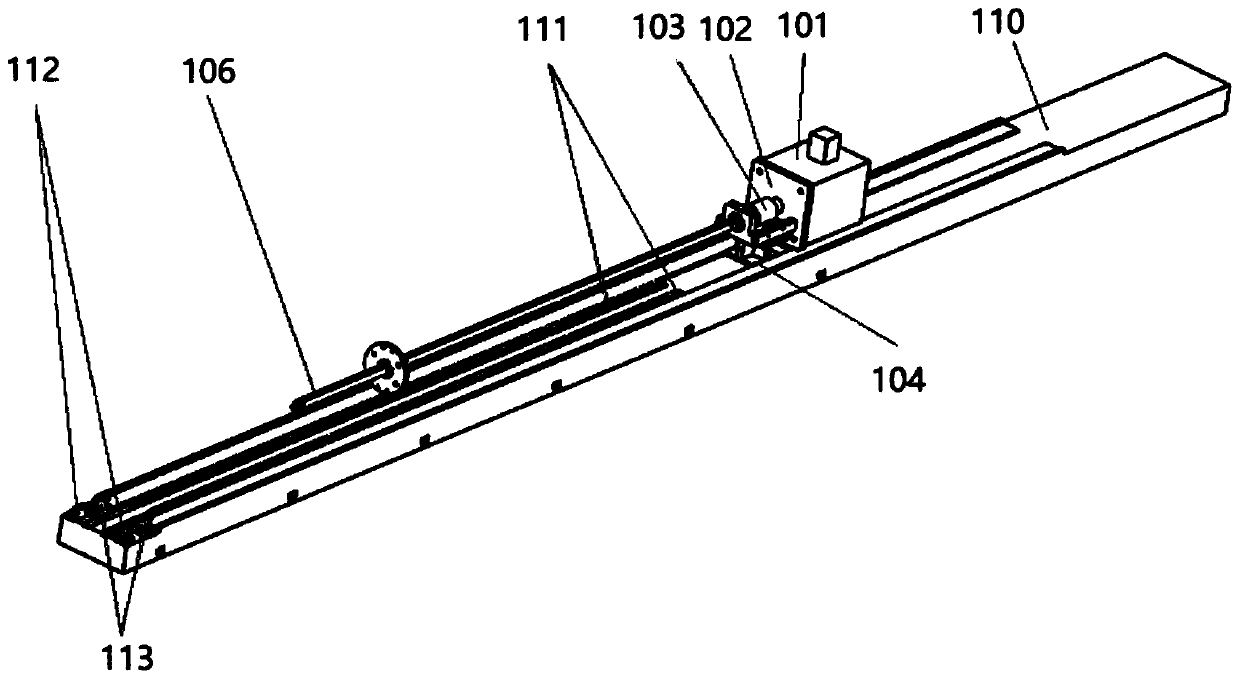

[0039] Such as figure 1 , 2 As shown, the lead screw nut transmission mechanism includes a lead screw 106 and a lead screw nut 107 , and also includes a lead screw nut covering member that is sleeved on the lead screw 106 and covers the installation end of the lead screw nut 107 . Wherein, the mounting end of the screw nut refers to a plate-shaped structure with an extension on one side of the normal screw nut, which belongs to the connection part directly fixedly connected with the driven part.

[0040]The above-mentioned lead screw nut covering part includes a fixed plate 109 and a rectangular covering cavity 108; the lead screw nut 107 is threadedly connected to the lead screw 106, and the mounting end of the lead screw nut is clamped in the covering cavity 108, Specifically, the mounting end of the lead screw nut is preferably in a rectangular structure, and the upper and lower sides of the mounting end are respectively attached to the upper and lower sides of the coating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com