Resin optical filter film crack detection device and method

A technology of detection equipment and detection methods, applied in the field of optical filters, can solve problems such as membrane cracks, hidden cracks, and difficult to clearly photograph membrane cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

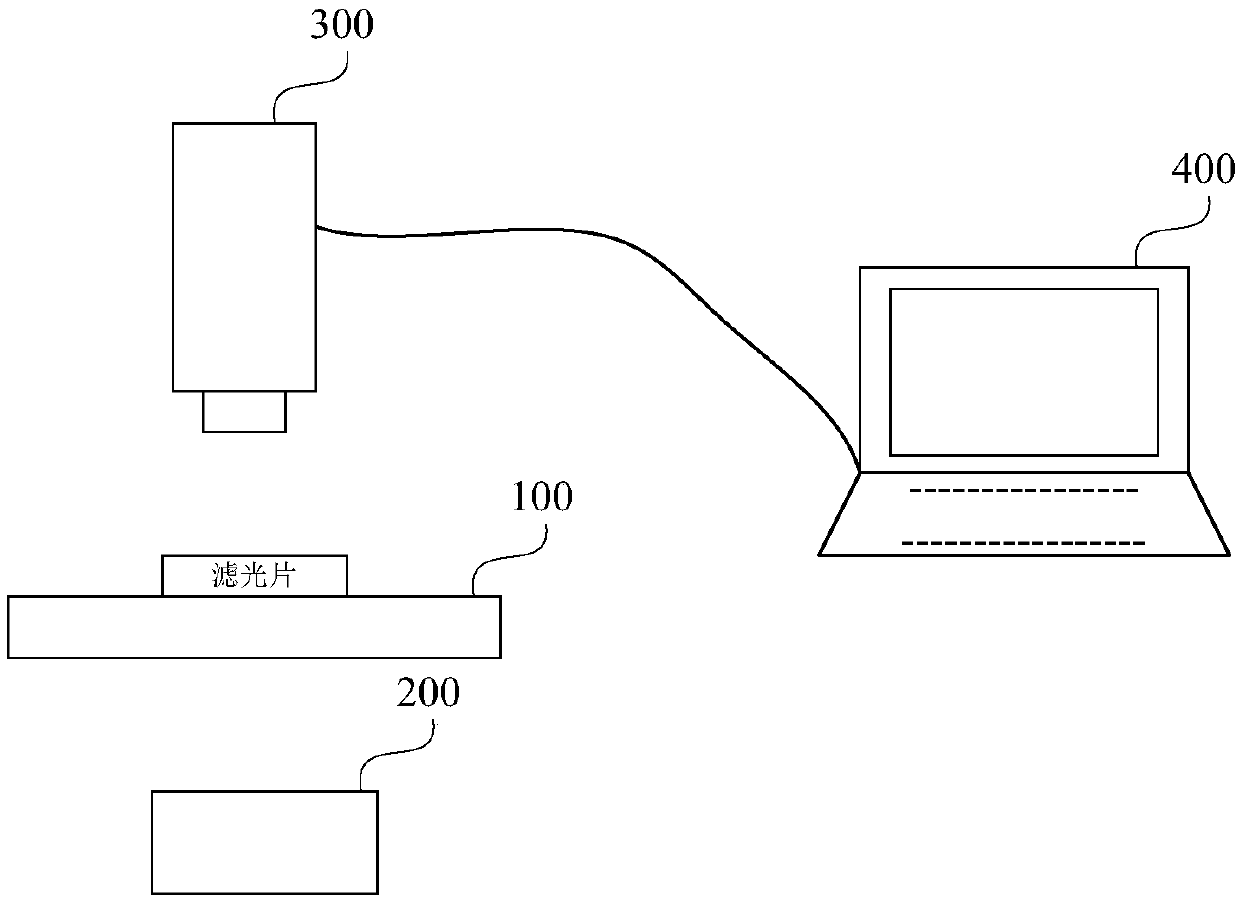

[0046] figure 1 It is a schematic structural diagram of a resin filter film crack detection device provided in Embodiment 1 of the present invention. like figure 1 As shown, the embodiment of the present invention provides a resin filter film crack detection device including a carrier device 100, a light source device 200, an image acquisition device 300, and an image processing and analysis system 400;

[0047] The carrying device 100 is used to carry the optical filter to be detected;

[0048] The light source device 200 is arranged under the carrying device 100 for illuminating the filter;

[0049] The image acquisition device 300 is arranged above the carrying device 100 and is arranged on the same vertical plane as the light source device 200, for acquiring and outputting the image information of the optical filter;

[0050] The image processing and analysis system 400 is configured to receive and process the image information of the optical filter output by the image ...

Embodiment 2

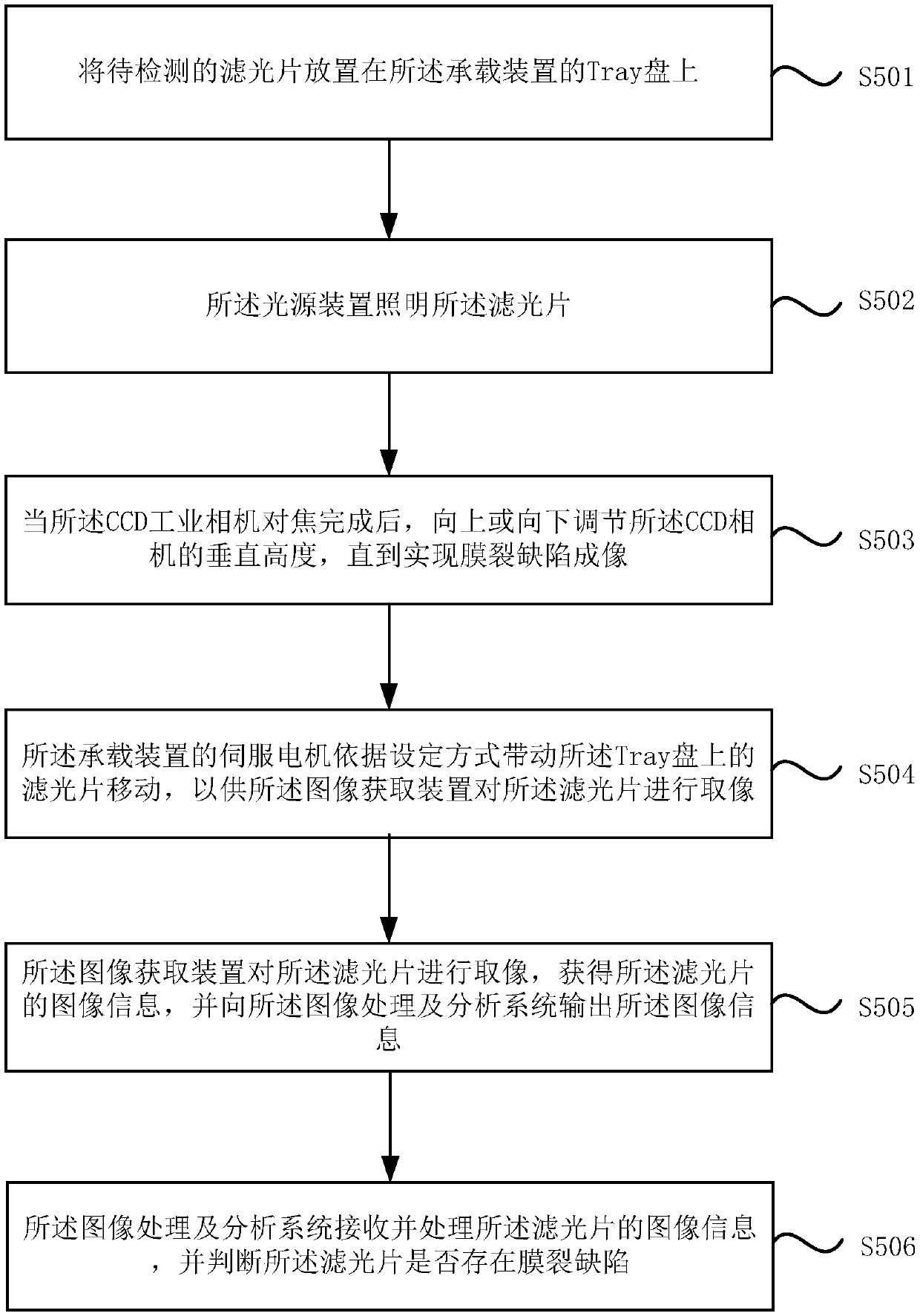

[0062] see figure 2 , is a schematic flowchart of a resin filter film crack detection method provided in Embodiment 2 of the present invention. The method is executed by the resin filter film crack detection system provided in the embodiment of the present invention, and the steps are as follows:

[0063] S501. Place the optical filter to be tested on the tray of the carrying device.

[0064] S502. The light source device illuminates the filter.

[0065] The light source device is arranged at a position below 20 mm from the optical filter on the carrying device, which includes a parallel blue light source and a Fresnel lens.

[0066] S503. After the CCD industrial camera is focused, adjust the vertical height of the CCD camera up or down until the imaging of membrane crack defects is realized.

[0067] This step has changed the traditional common focusing form, and continued to adjust the vertical height of the camera based on the traditional clear focus, so as to realize ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com