Frequency converter load test system

A technology of load testing and inverter, applied in the field of inverter testing, can solve problems such as inability to test and trouble, and achieve the effect of reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

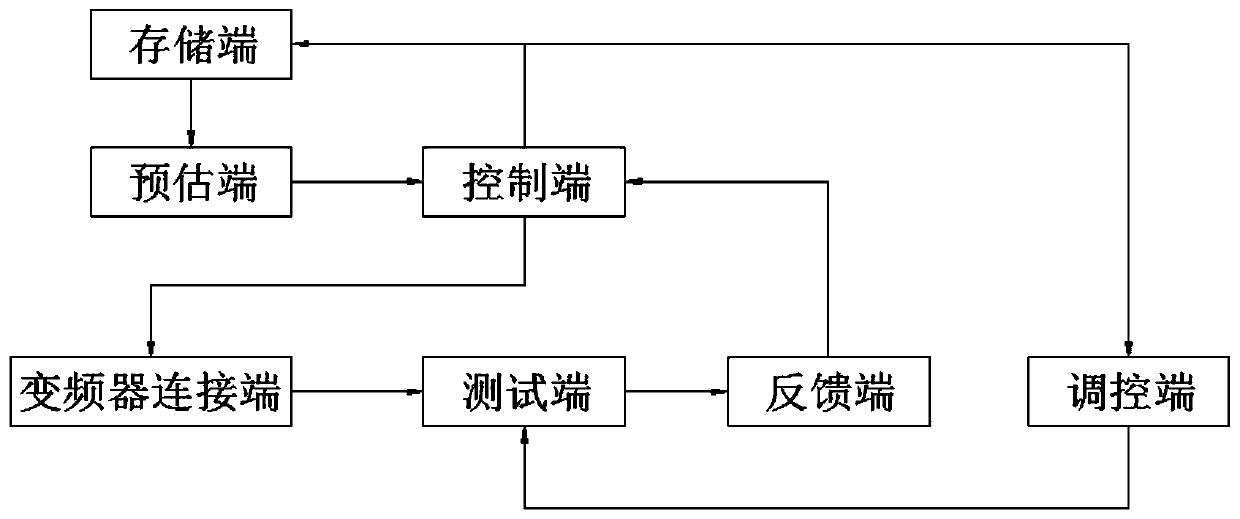

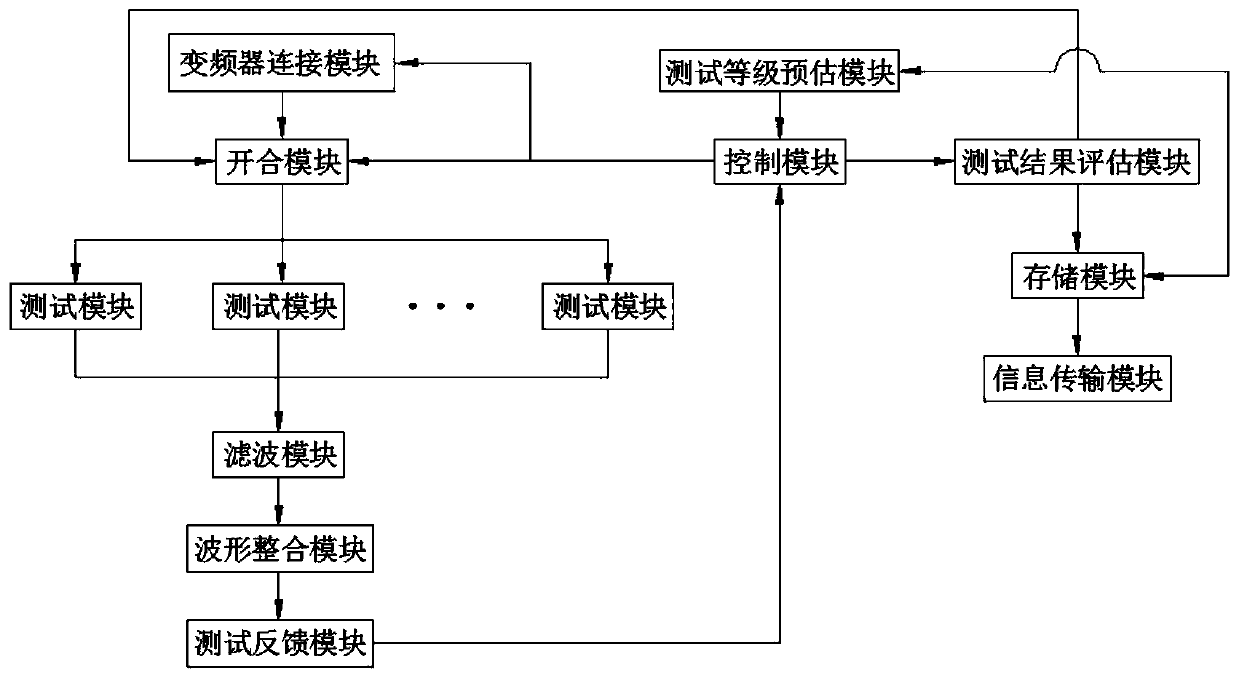

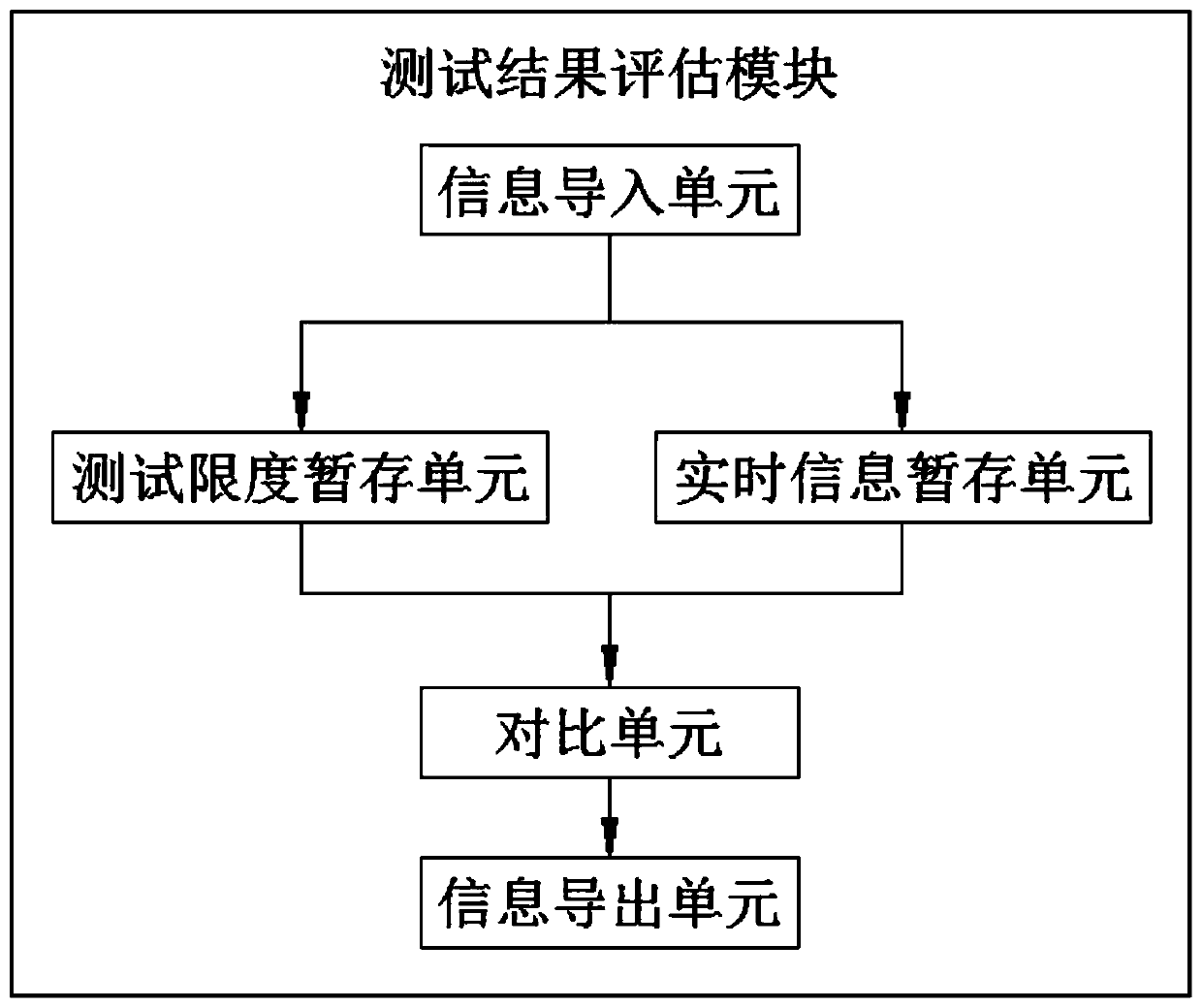

[0027] refer to Figure 1-5 In this embodiment, a load test system for a frequency converter is proposed, including a storage terminal, an estimation terminal, a control terminal, a frequency converter connection terminal, a test terminal, a feedback terminal, and a regulation terminal. The control terminal includes a control module, and the estimation terminal includes a The test level estimation module, the storage terminal includes the storage module and the information transmission module, the inverter connection terminal includes the inverter connection module and the opening and closing module, the test terminal includes the filter module, the waveform integration module and multiple test modules, and the feedback terminal includes the test feedback module, the control end includes a test result evaluation module; the test level estimation module and the test feedback module are connected to the control module, the control module, the test result evaluation module and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com