Polar pitch variable rectilinear vortex brake and controlling method thereof

A linear eddy current braking, variable technology, applied in the control of electromechanical brakes, asynchronous inductive clutches/brakes, control systems, etc., to achieve the effects of high reliability, simple device structure, and improved system testing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

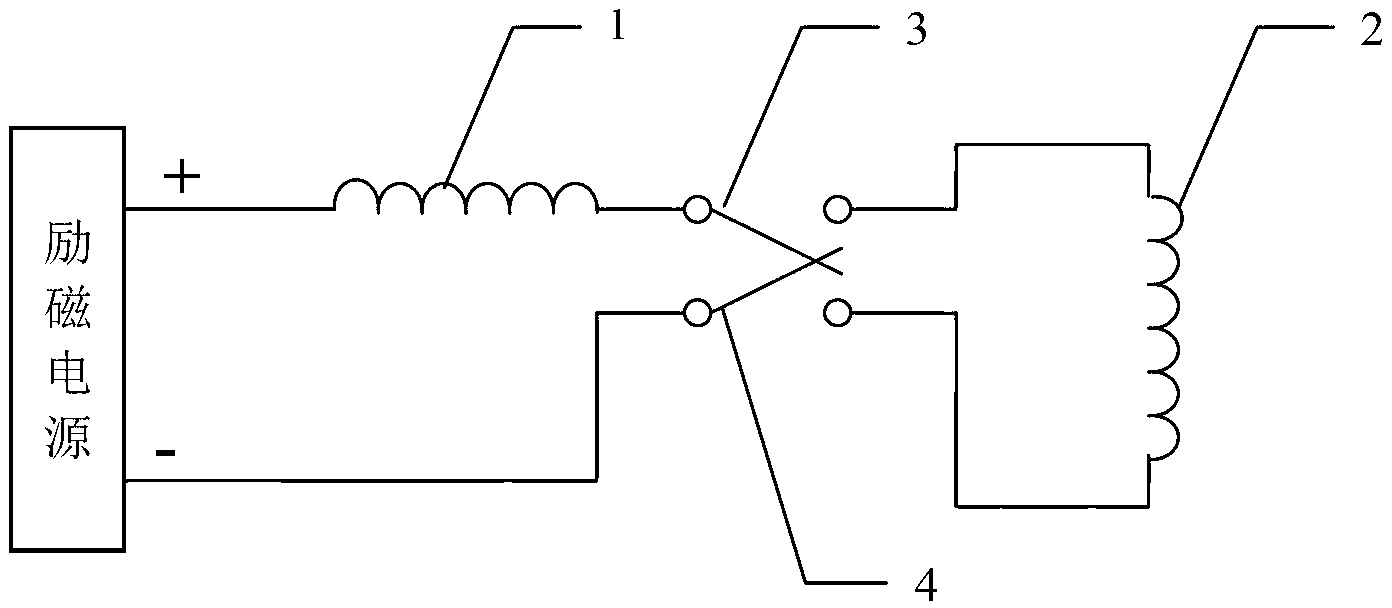

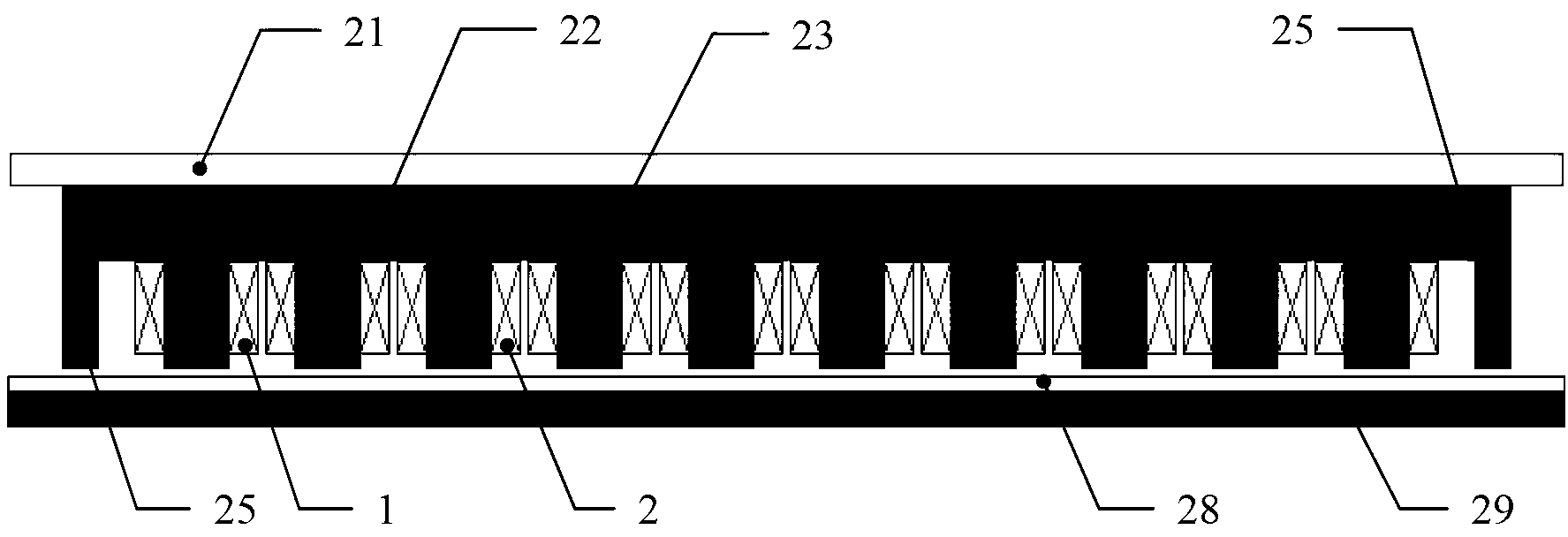

[0039] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT 1. A variable pole pitch linear eddy current brake described in this embodiment includes a primary and a secondary, and an air gap exists between the primary and the secondary; the primary includes a primary fixed plate 21 and a primary iron core 22 and field windings;

[0040] The primary iron core is fixed on the primary fixing plate; the surface of the primary iron core facing the air gap side has a tooth groove structure, and the even number of armature teeth 23 are arranged along the relative movement direction of the primary and secondary, and each armature tooth is wound with One coil; the coils on the (4n-3)th armature tooth and the (4n-2)th armature tooth are reversely connected in series to form the first excitation winding 1; the (4n-1)th armature tooth and the (4n-1)th armature tooth and The coils on the (4n)th armature tooth are reversely connected in series to form the second excitation winding 2, where n is...

specific Embodiment approach 2

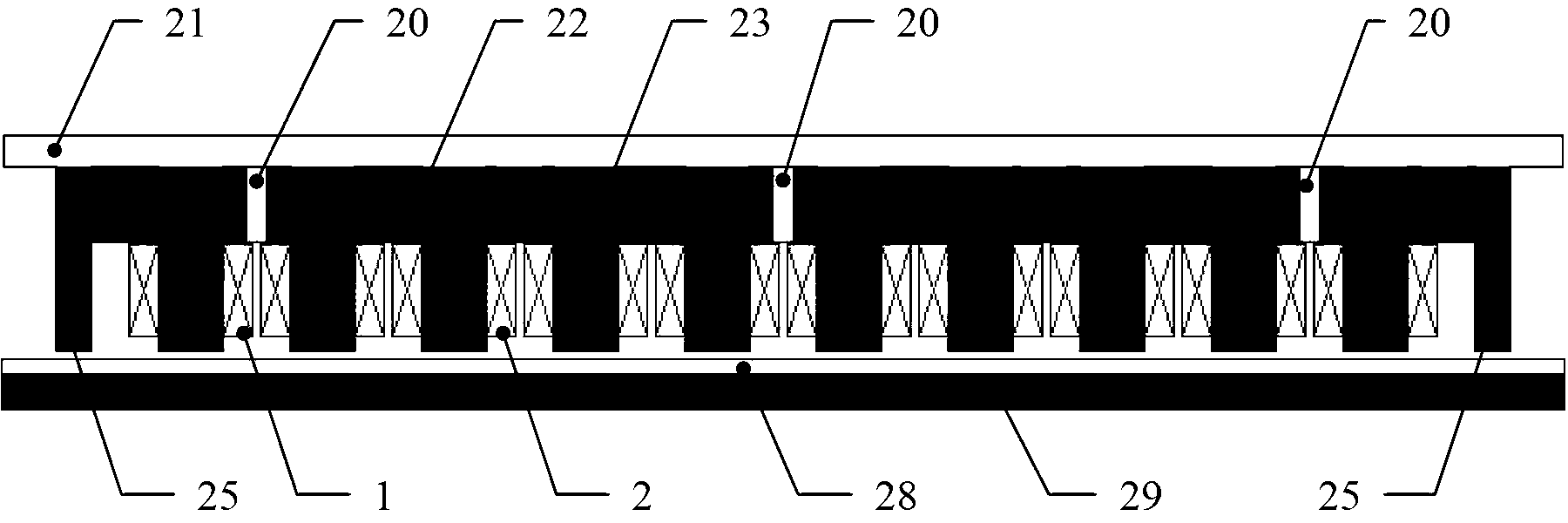

[0043]Specific Embodiment 2. The difference between this embodiment and the variable pitch linear eddy current brake described in Embodiment 1 is that the (4n-3)th armature tooth and the (4n-2th) armature tooth of the armature core ) A permanent magnet 20 is embedded in the yoke between two armature teeth, and the magnetization direction of the permanent magnet 20 is parallel to the relative movement direction of the primary and secondary.

[0044] see image 3 Describe the specific structure of a pole-pitch variable linear eddy-current brake described in this embodiment: the structure is based on the structure of the pole-pitch variable linear eddy-current brake described in the first specific embodiment. The yoke between the 1st armature tooth and the 2nd armature tooth is grooved along the transverse direction, and the permanent magnet 20 is embedded in the slot, and the yoke between the 5th armature tooth and the 6th armature tooth is Grooving horizontally, embedding perm...

specific Embodiment approach 3

[0045] Specific Embodiment 3. The difference between this embodiment and the variable pitch linear eddy current brake described in Embodiment 1 is that the (4n-3)th armature tooth and the (4n-2th) armature tooth of the armature core ) A plate-shaped permanent magnet 30 is respectively fixed on the air gap surface of each armature tooth, the magnetization direction of the permanent magnet 30 is perpendicular to the relative movement direction of the primary and secondary, and the magnetization of two adjacent permanent magnets in the opposite direction.

[0046] see Figure 4 Describe the specific structure of a pole-pitch variable linear eddy-current brake described in this embodiment: the structure is based on the structure of the pole-pitch variable linear eddy-current brake described in the first specific embodiment. One armature tooth, the second armature tooth, the fifth armature tooth, the sixth armature tooth, the ninth armature tooth, and the tenth armature tooth are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com