Built-in line-shaped/U-shaped series-parallel hybrid magnetic circuit adjustable magnetic flux permanent magnet synchronous motor

A permanent magnet synchronous motor and hybrid magnetic circuit technology, which is applied to synchronous motors with stationary armatures and rotating magnets, synchronous machine parts, magnetic circuit rotating parts, etc., to achieve reduced magnetic flux leakage, small demagnetization current, Effect of increased power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

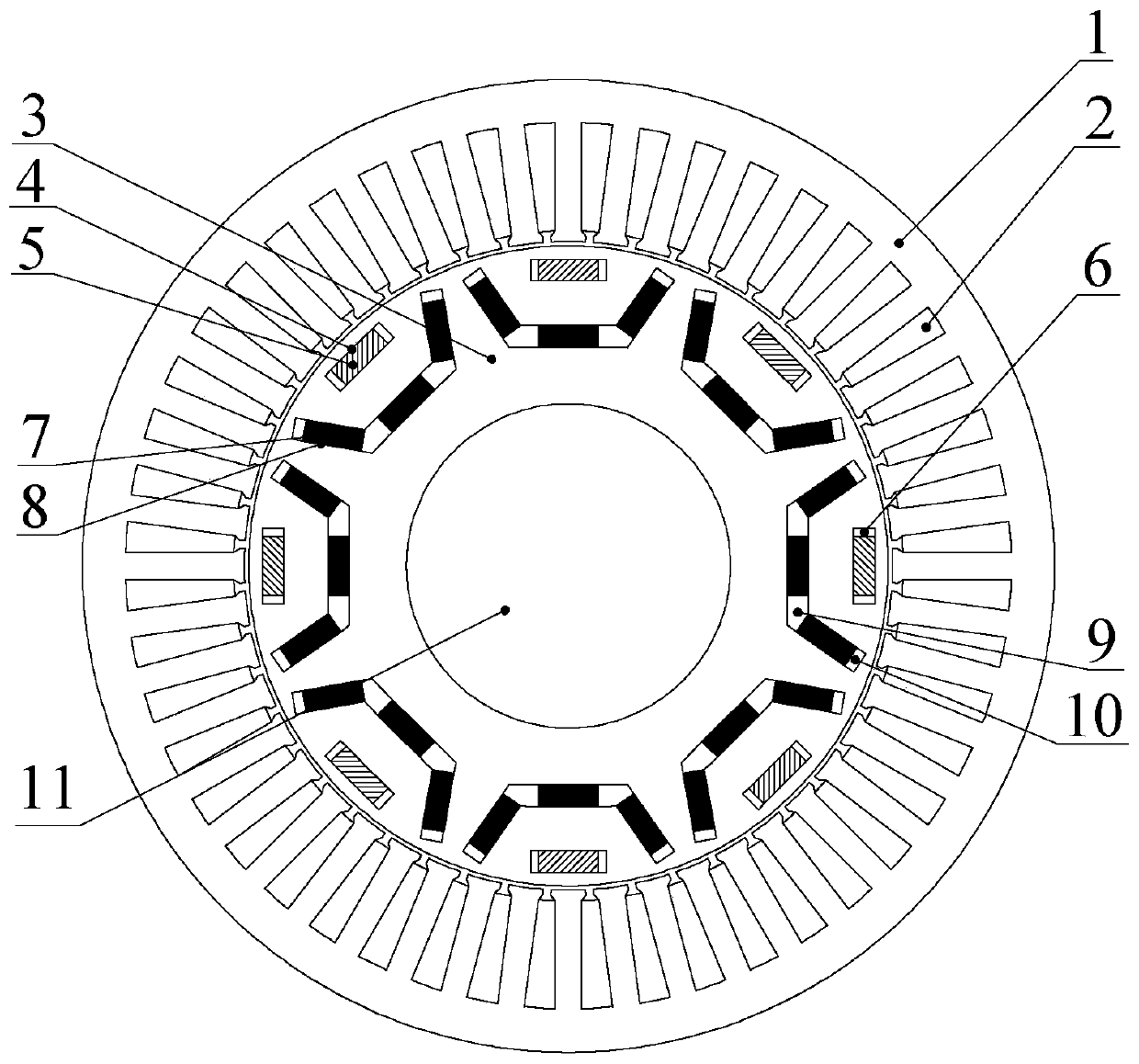

[0021] Embodiment 1: see figure 1 The motor of the present invention includes a stator core 1, an armature winding 2, a rotor core 3, a rotating shaft 11, a low-coercivity permanent magnet 5, a high-coercivity permanent magnet 7, a first magnetic isolation slot 6, and a second magnetic isolation slot 9 and the third magnetic isolation slot 10; the rotor core 3 is fixed on the rotating shaft 11, the armature winding 2 is located in the stator core 1, and there is a radial air gap between the stator core 1 and the rotor core 3;

[0022] The rotor core 3 has multiple permanent magnets built into the body on the air gap side to form a P pair of magnetic poles. Each magnetic pole includes a low-coercivity permanent magnet 5 and three high-coercivity permanent magnets 7, and three high-coercivity permanent magnets 7 Set up a U-shaped structure symmetrically with the direct axis of the magnetic pole rotor as the line of symmetry, and the opening faces the radial air gap. A low-coerci...

Embodiment 2

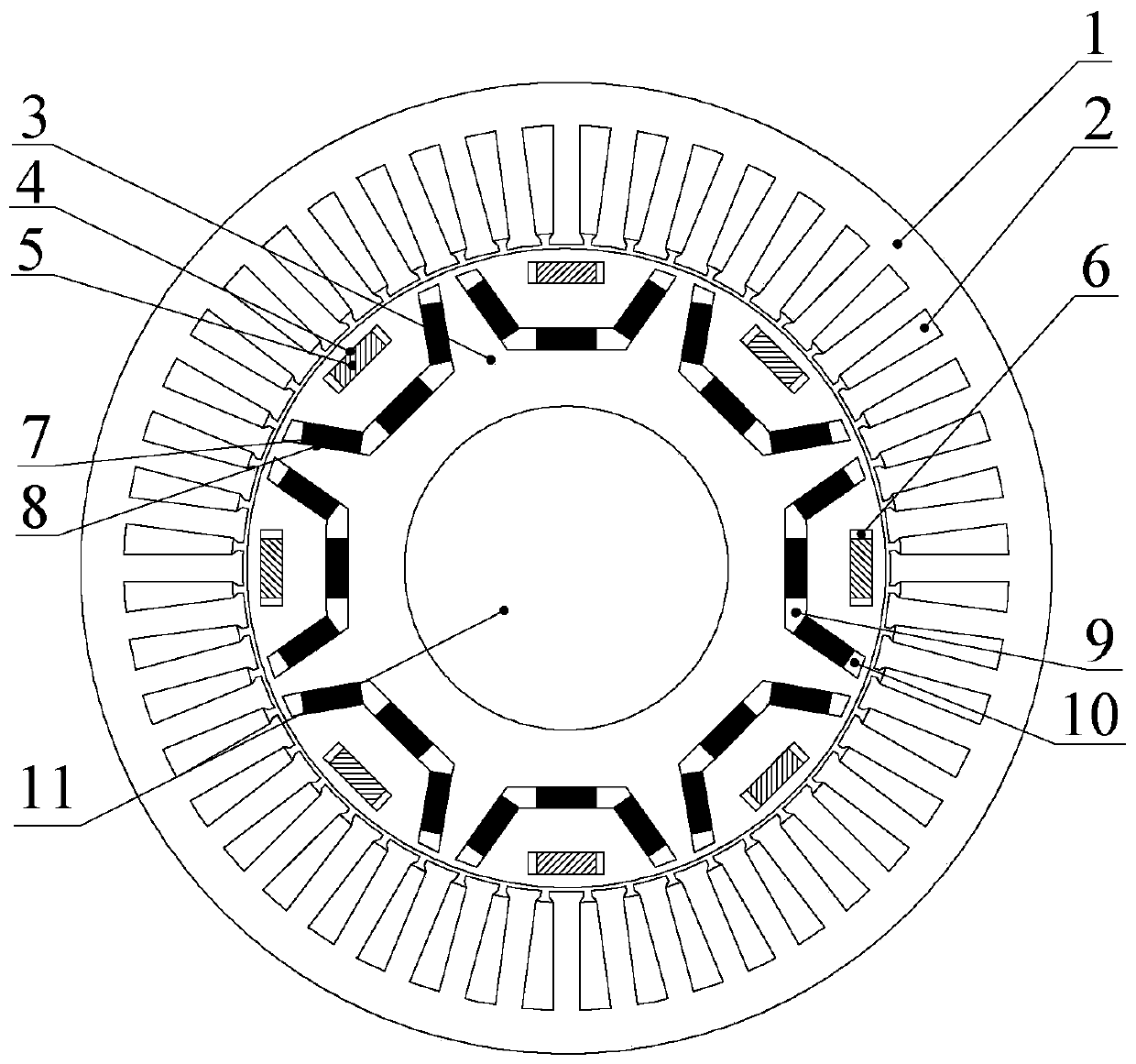

[0029] Example 2: see figure 2 , Improvement is made on the basis of Embodiment 1, the radial section of the third magnetic isolation slot 10 is trapezoidal.

[0030] The purpose of this embodiment is to form a magnetic bridge on the air gap side of the rotor to limit the magnetic flux passing through the magnetic bridge, which can not only reduce the magnetic flux leakage of the high coercivity permanent magnet 7 caused by its own short circuit, but also reduce the adjacent The flux leakage between the high-coercivity permanent magnets 7 between the two magnetic poles improves the air-gap magnetic density, and the power density of the motor increases.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com