Spiral-rail vertical farm electric material broadcasting and sowing all-in-one machine

A technology of spiral track and integrated machine, which is applied in the direction of seeder parts, fertilizers, planting equipment, and sowing, can solve the problems of easy dust, environmental pollution, uneven and inaccurate application, etc., so as to improve the dust problem and improve the application rate. The effect of spreading efficiency and improving the uniformity of spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

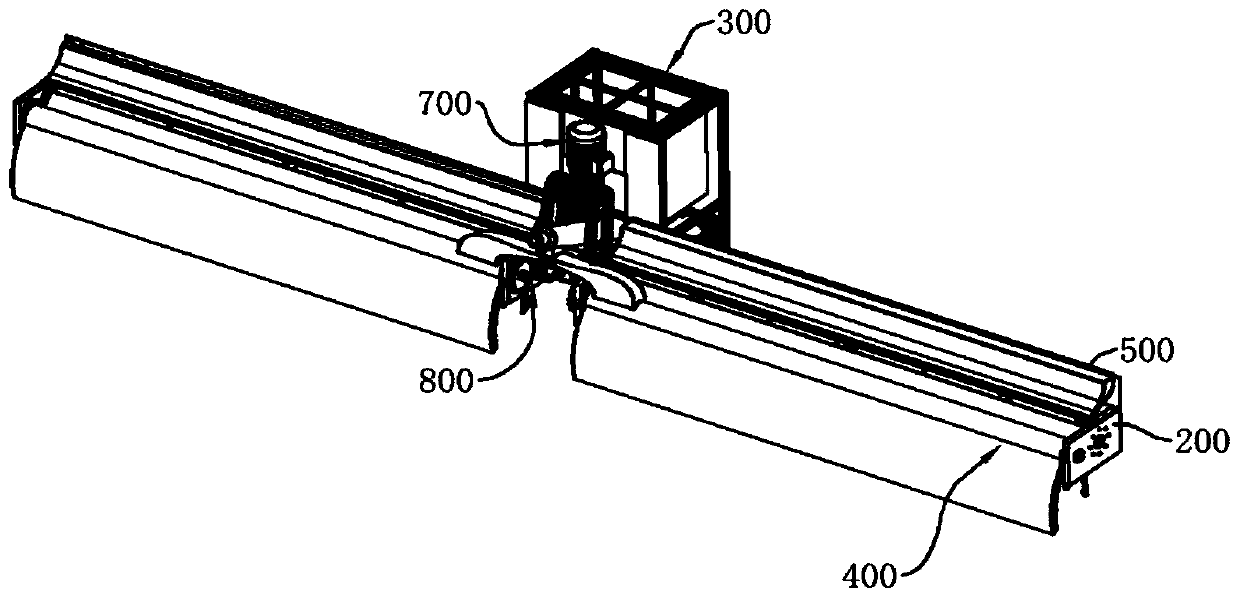

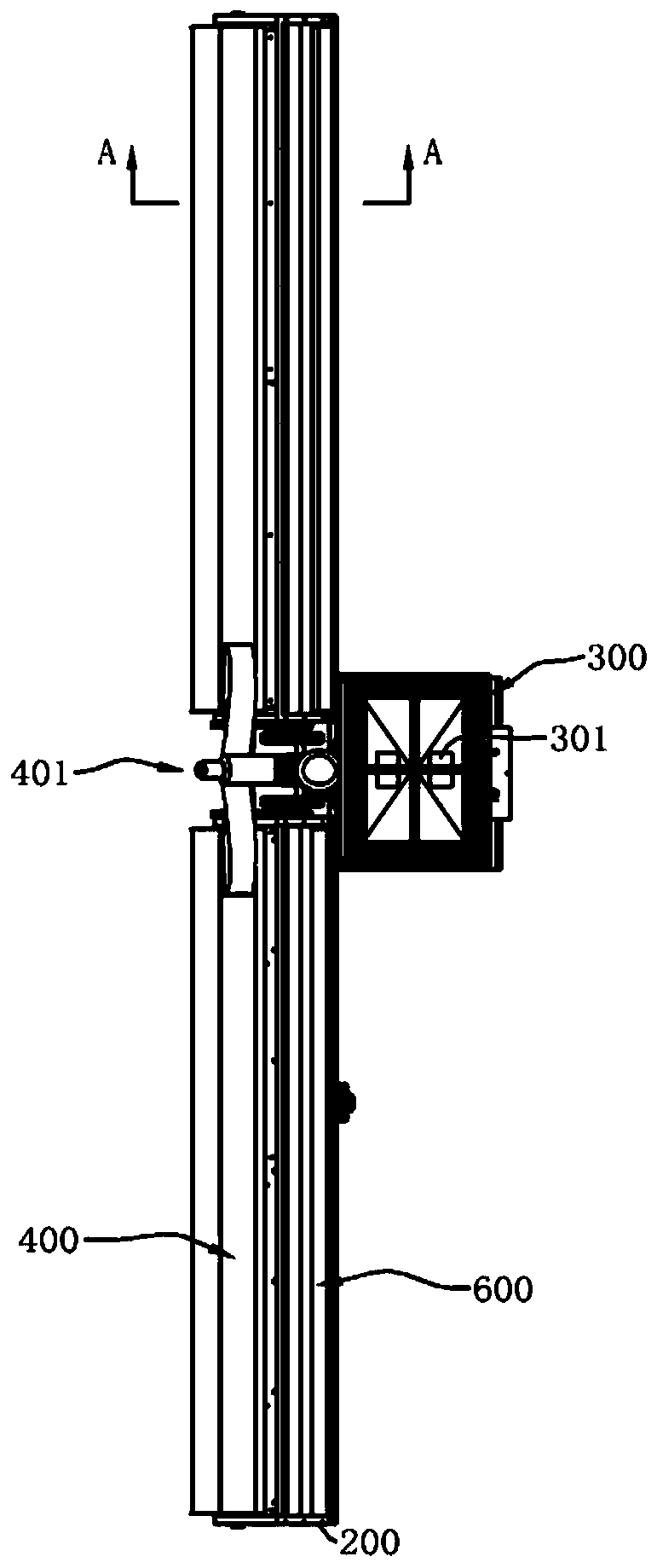

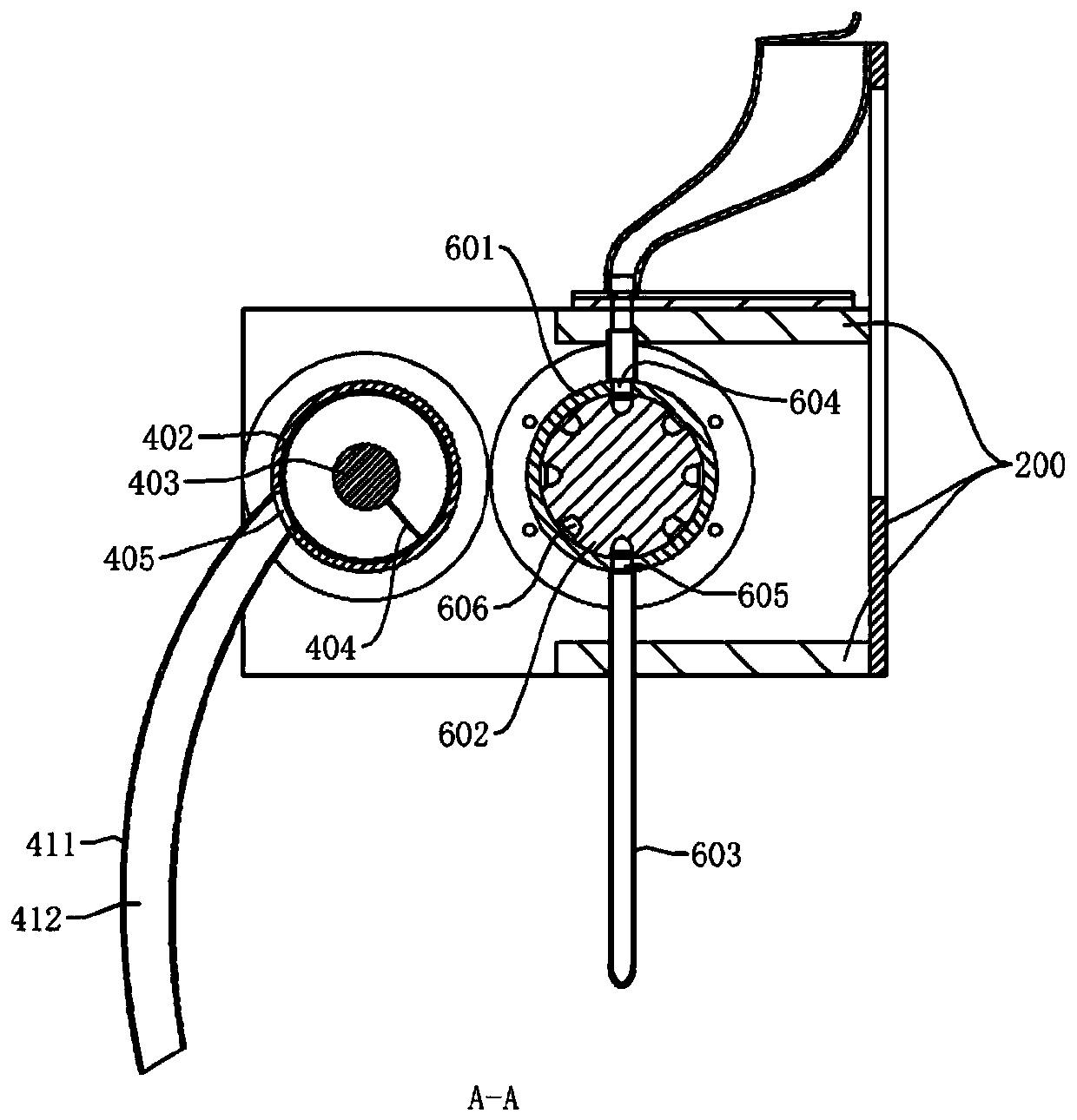

[0068] An electric material spreading and seeding integrated machine for spiral track vertical farms, refer to figure 1 , figure 2 , image 3 and Figure 12 , including a transport vehicle 100, a fixed frame 200, a solid material box 300, a solid material spreading device 400, a seed storage tank 500, a seed spreading device 600, a driving device 700 and a transmission assembly 800; the solid material box 300 is connected to the fixed frame 200 , the fixed frame 200 is fixedly connected with the transport vehicle 100; the solid material spreading device 400 includes a feeding channel 401, a feeding pipe 402, a transmission shaft 403 and a screw blade 404; the solid material box 300 passes through the feeding channel 401 and the feeding pipe 402 Connected, there is a feeding port 405 on the feeding pipe 402, and the feeding port 405 is arranged along the feeding pipe 402; the transmission shaft 403 and the spiral blade 404 are inserted inside the feeding pipe 402, and the fe...

Embodiment 2

[0081] An electric material spreading and seeding integrated machine for spiral track vertical farms, the difference from Embodiment 1 is that the seeds are stored in the seed storage tank 500, and the seeds enter the feeding port 604 and the quantitative transfer tank in sequence during the working process 606, the discharge port 605 and the sowing tube 603, and finally drop from the sowing tube 603 to the planting surface.

[0082] Such as Figure 13 As shown, an adjustment plate 414 is slidably connected to the feed pipe 402, a linear module 415 is fixedly connected to the feed pipe 402, the guide rail of the linear module 415 is fixedly connected to the feed pipe 402, and the slide block of the linear module 415 is connected to the feed pipe 402. The adjustment plate 414 is fixedly connected, the sliding direction of the adjustment plate 414 relative to the feed pipe 402 is perpendicular to the central axis of the feed pipe 402, and the sliding direction of the slide block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com