Powder extractor

An extractor and powder technology, which is applied in chemical instruments and methods, solid solvent extraction, solvent extraction, etc., can solve the problems of low economic return rate, decreased effluent flow, blocked effluent pipe valves, etc., and can extend the extraction process. , the solid-liquid mixing is sufficient, and the effect of improving the mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In the following description of the present invention, the orientation or positional relationship indicated by the terms "upper", "lower", "front", "rear", "left", "right", "inner", "outer" etc. are based on the attached The orientation or positional relationship shown in the figure is only for the convenience of describing the present invention and simplifying the description, and does not mean that the device must have a specific orientation.

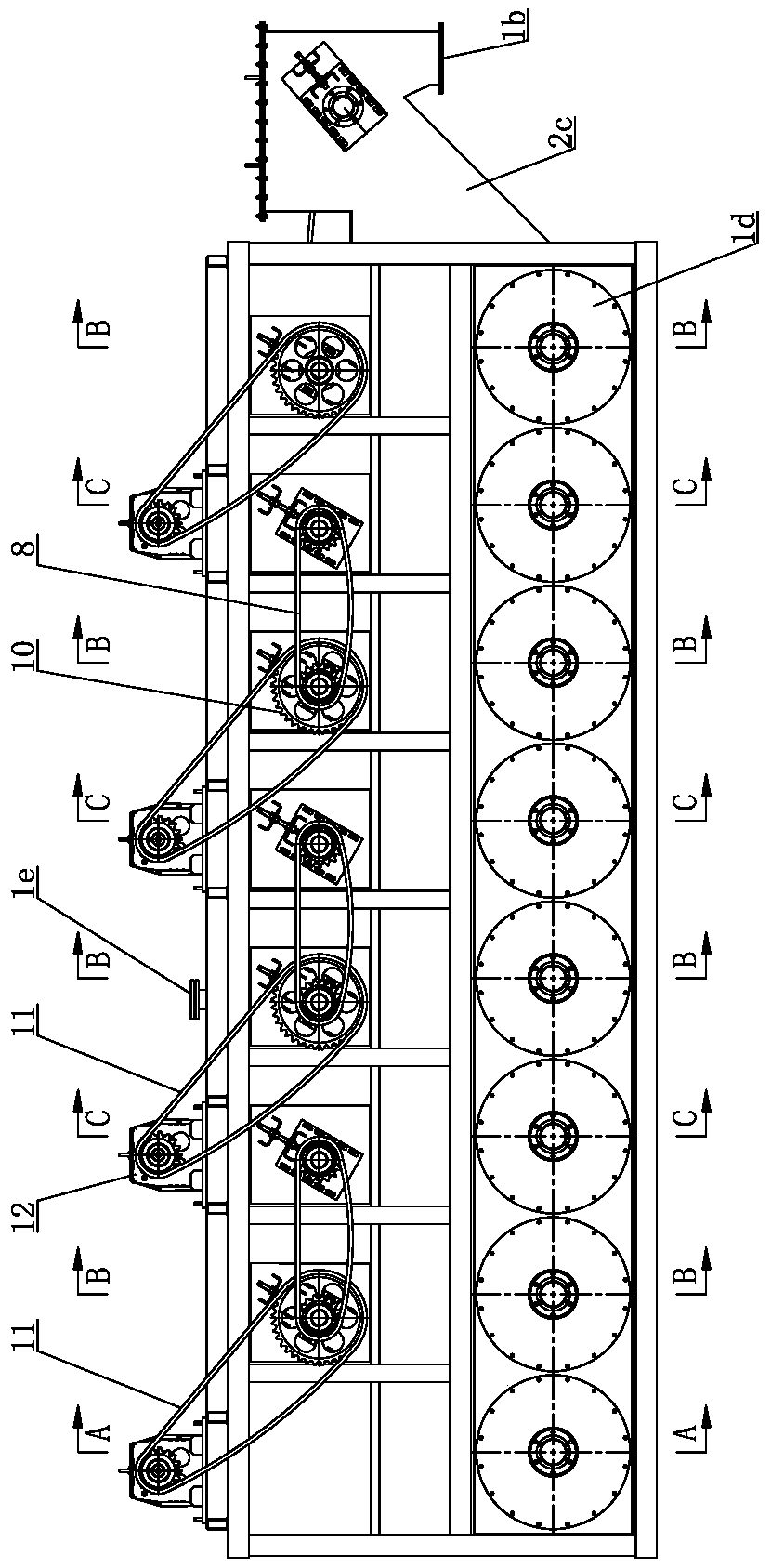

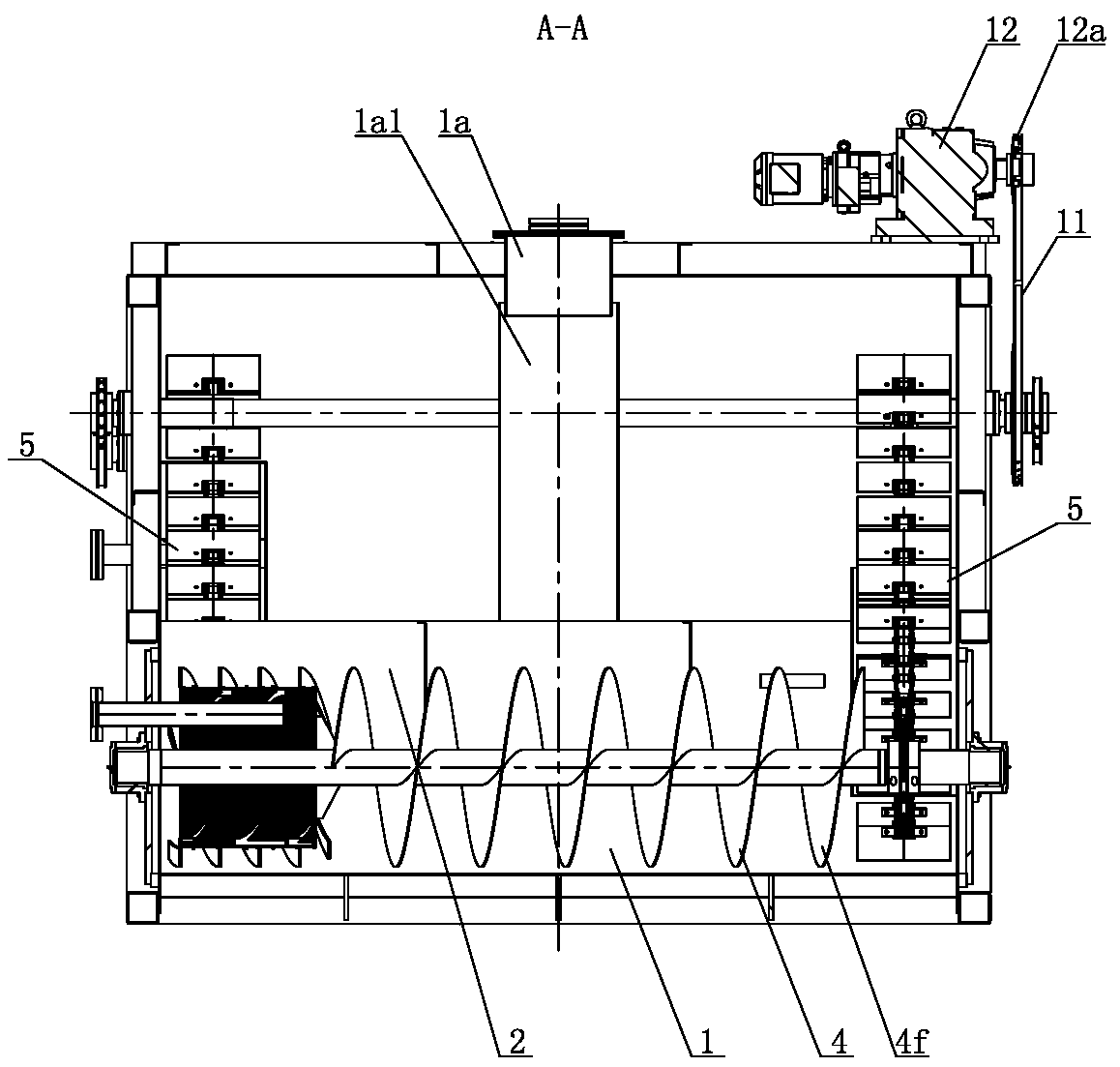

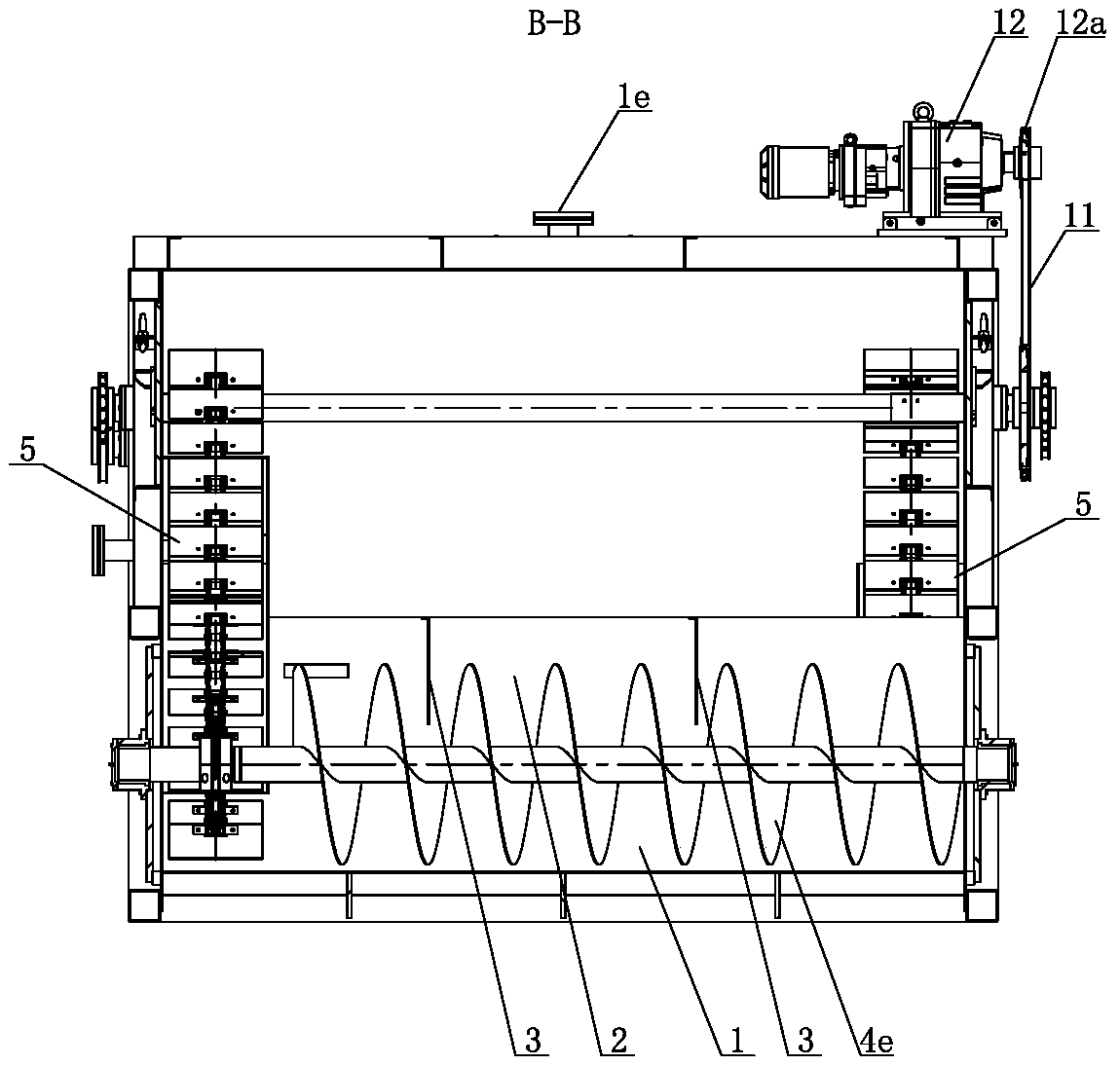

[0035] Such as Figure 1 to Figure 13 As shown, the powder extractor of the present invention includes a rectangular box, and the top of the box is provided with an exhaust hole 1e and a manhole. The front and rear wallboards of the box are connected with multiple parallel tank partitions 2, and each tank partition 2 divides the inner cavity of the cabinet into a plurality of soaking tanks 1, and the upper part of each tank partition 2 is respectively equipped with The overflow ports 2a, the overflow ports 2a on the adjacent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com