Grinding wheel dresser

A grinding wheel dresser and grinding wheel technology are applied in abrasive surface adjustment devices, parts of grinding machine tools, metal processing equipment, etc., which can solve problems such as low correction efficiency, poor product stability, and low product accuracy, and achieve high machining accuracy. Good stability and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

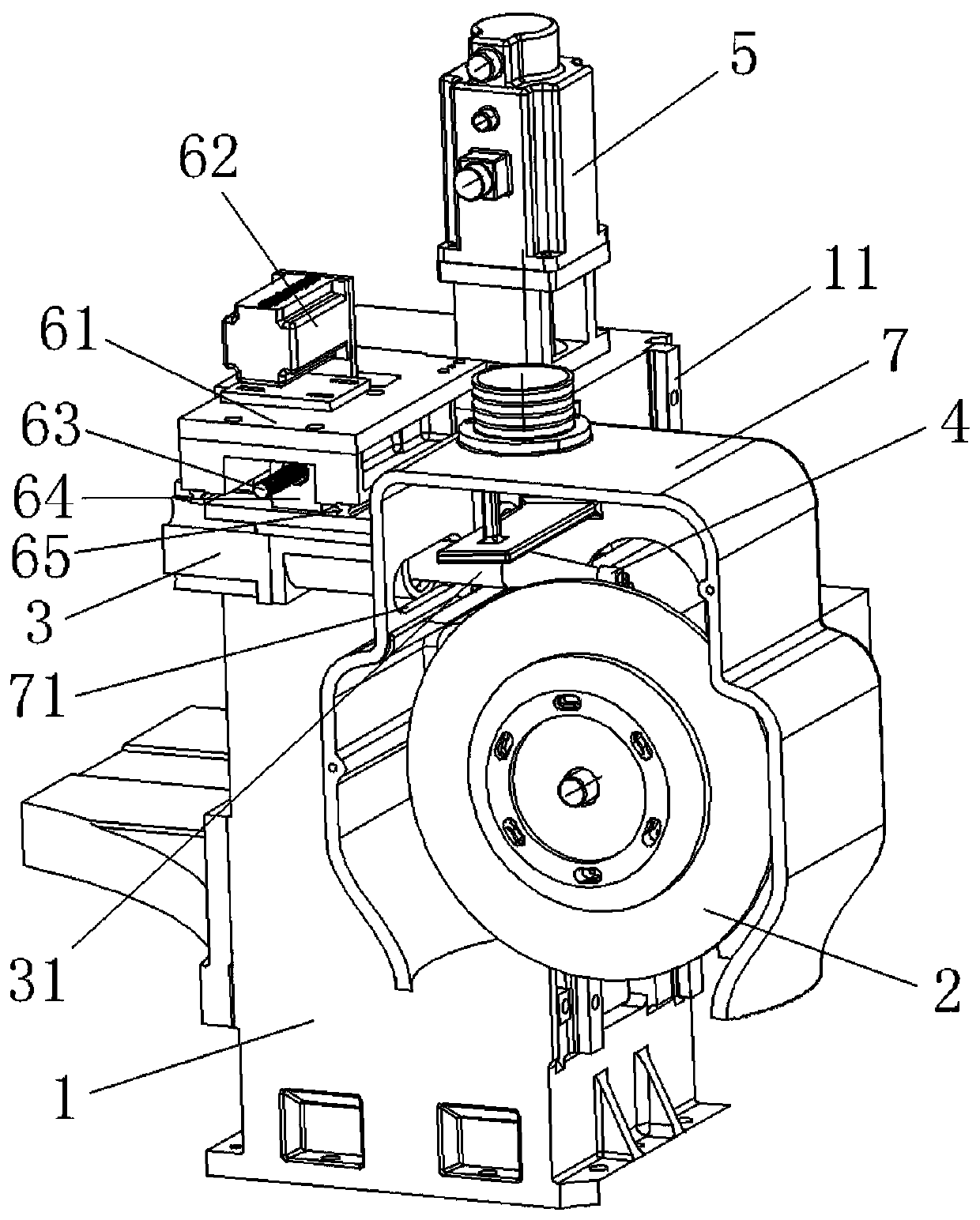

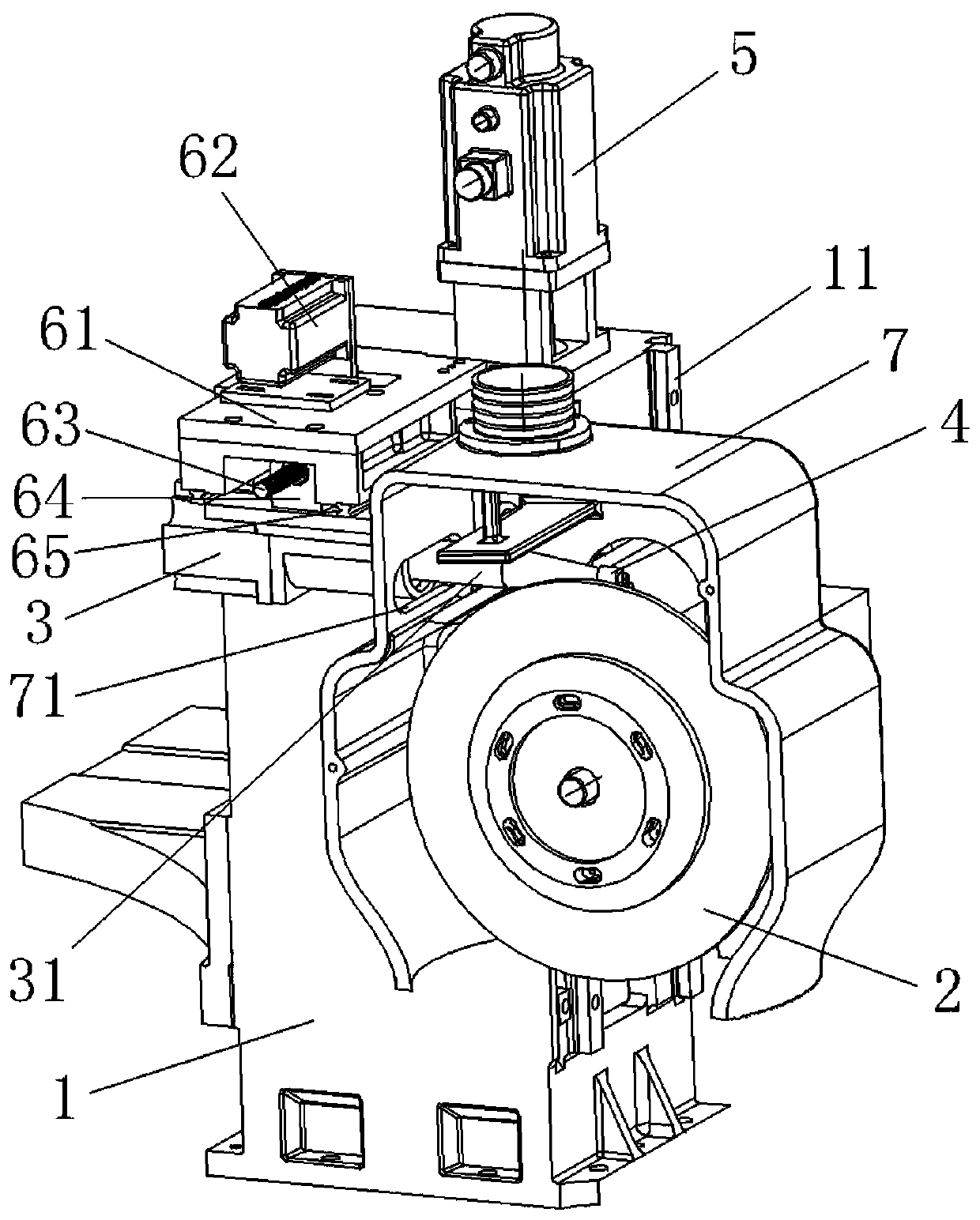

[0016] Such as figure 1 The shown grinding wheel dresser includes a stand 1, a grinding wheel 2 arranged on the stand 1, and a diamond roller 4 driven by a roller rotary shaft motor 3 above the grinding wheel 2. The axis of the diamond roller 4 is aligned with the axis of the grinding wheel 2. vertical. Such as figure 1 As shown, there is a linear guide rail 11 vertically arranged on the first side of the stand 1, and the grinding wheel 2 is arranged on the linear guide rail 11. The top surface of the stand 1 has a Z-axis servo that drives the grinding wheel 2 to move up and down along the linear guide rail 11 The motor 5 and the diamond roller 4 are arranged on the adjacent side perpendicular to the first side, and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap