A side-mounted case separation system

A separate system and side-mounted technology, applied in the field of transportation and logistics, can solve the problems of high initial investment, technical requirements, maintenance costs, and large occupied space, and achieve the effect of small track beam width, reduced cost, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

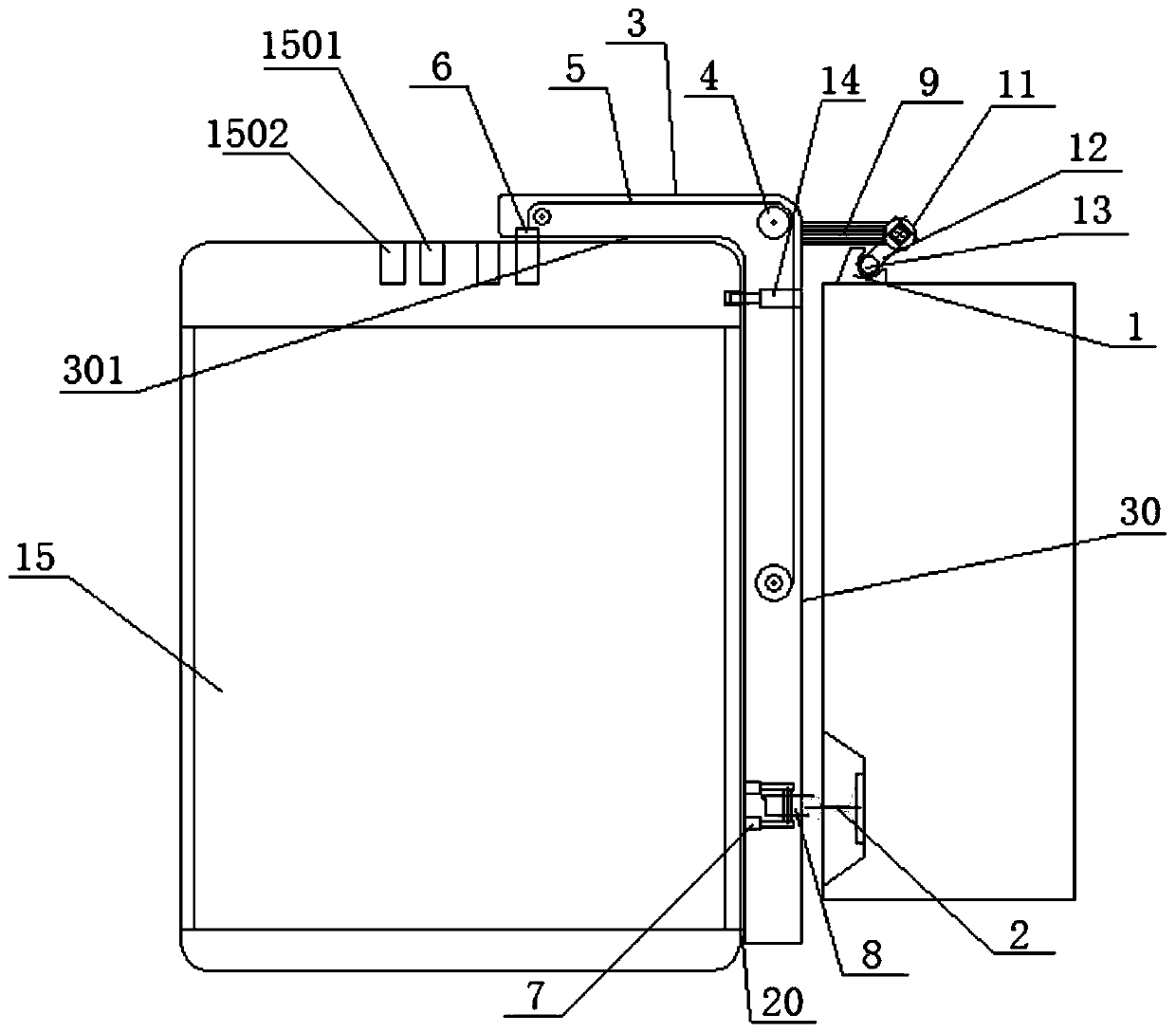

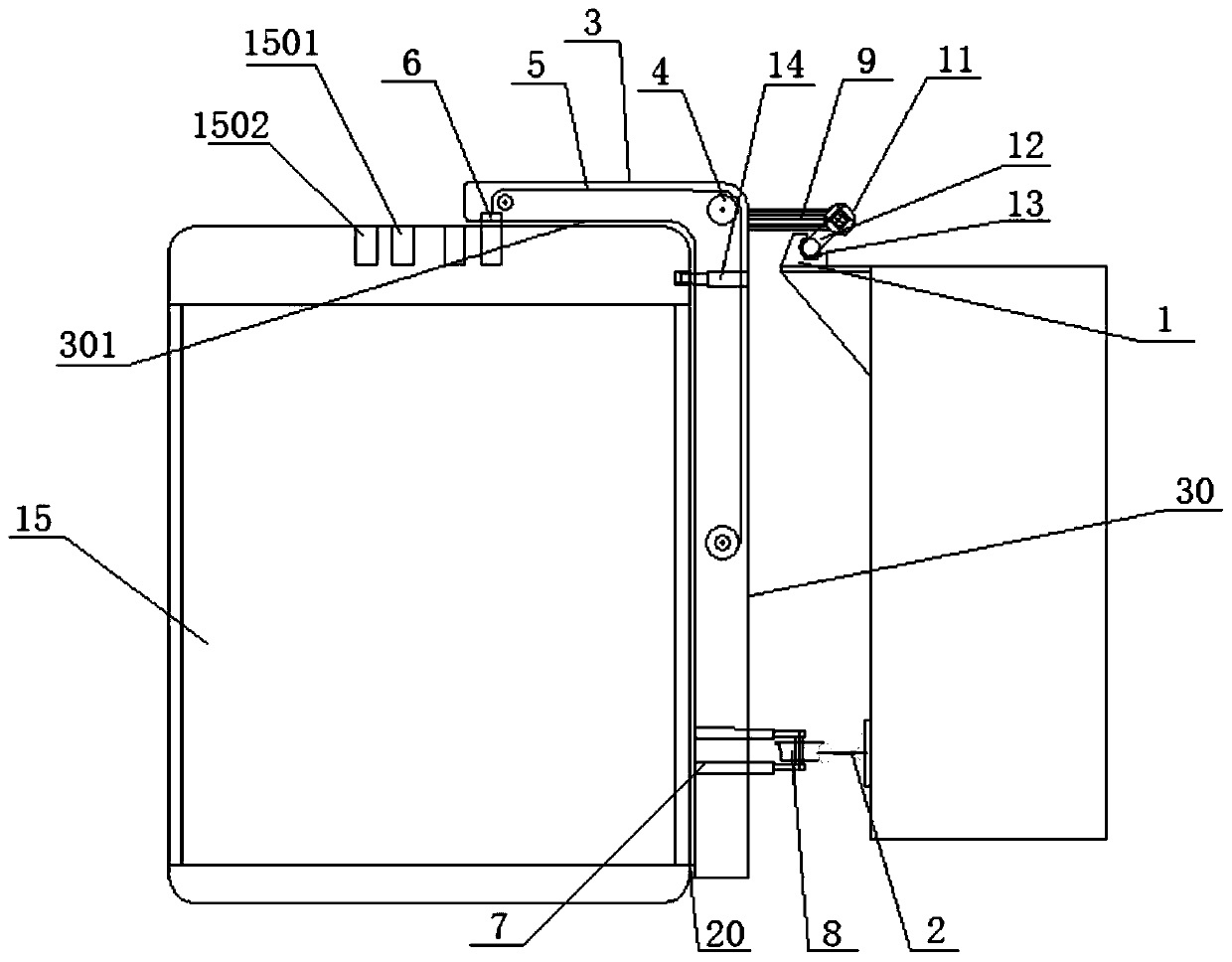

[0065] see Figure 1 to Figure 11 , a side-mounted case separation system is characterized in that it includes a track part, a transport part, a car part and a central control system.

[0066] The track portion includes a main vehicle track beam. A U-shaped track 1 is arranged on the top of the track beam of the main vehicle. A running rail 2 is provided on the side wall of the main vehicle track beam.

[0067] The transportation part is located on the side of the main vehicle track beam, and includes a hoisting system, a running system and a suspension system.

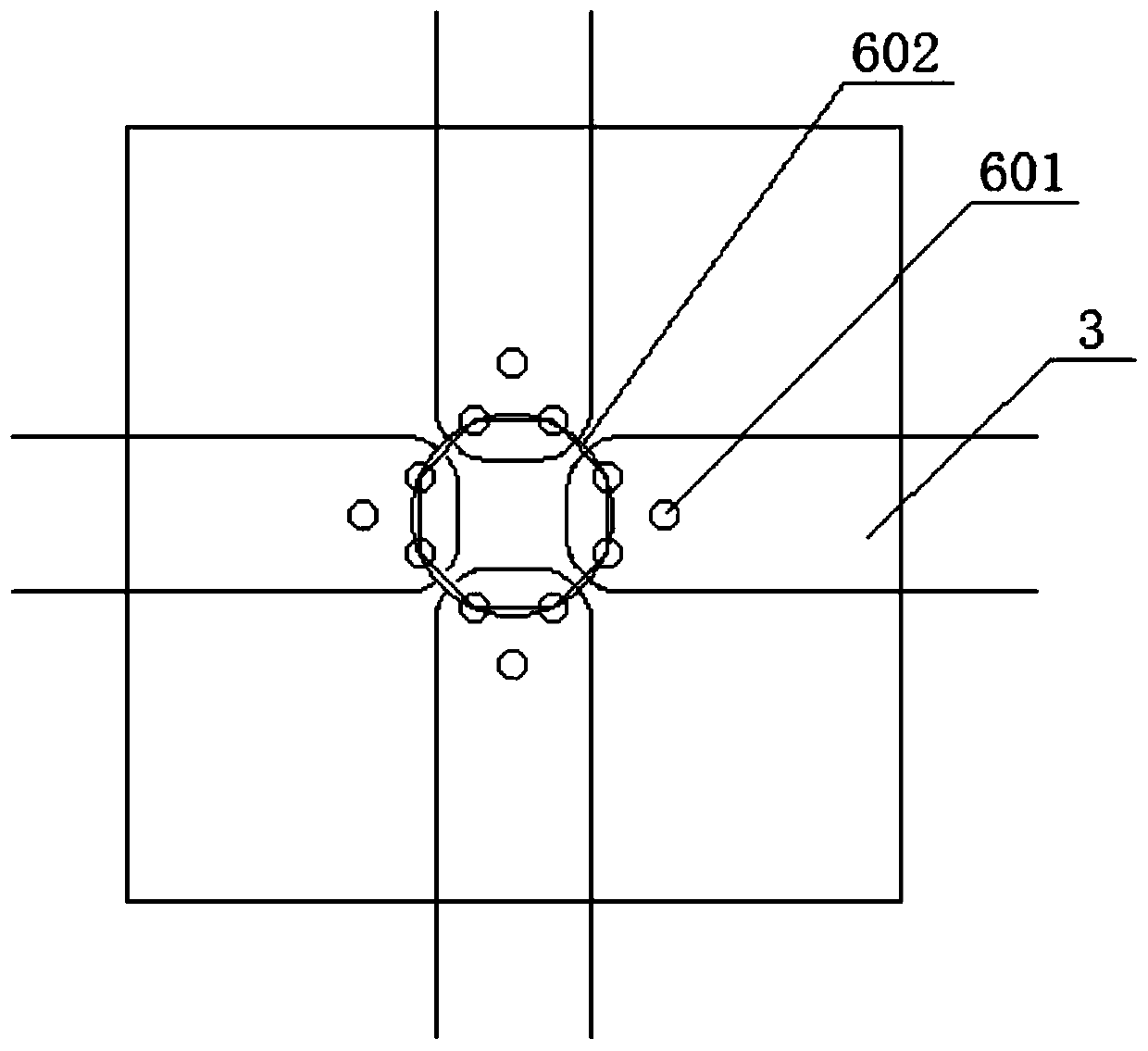

[0068] The hoisting system includes a suspension beam 3 , a rotating wheel 4 , a rope 5 and a hoisting part 6 .

[0069] The suspension beam 3 includes an upper beam 301 and a lower beam 302 .

[0070] The upper beam 301 and the lower beam 302 are connected in an inverted L shape.

[0071] A plurality of the rotating wheels 4 are mounted on the upper beam 301 and the lower beam 302 .

[0072] The rope 5 is wound...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com