An automatic palletizing fixture

A palletizing and jig technology, applied in the field of automatic packaging, can solve the problems of large packaging box, high reliability requirements of palletizing devices, and rigid impact of products, so as to improve the efficiency of palletizing and reduce product drop damage. , to ensure the effect of work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

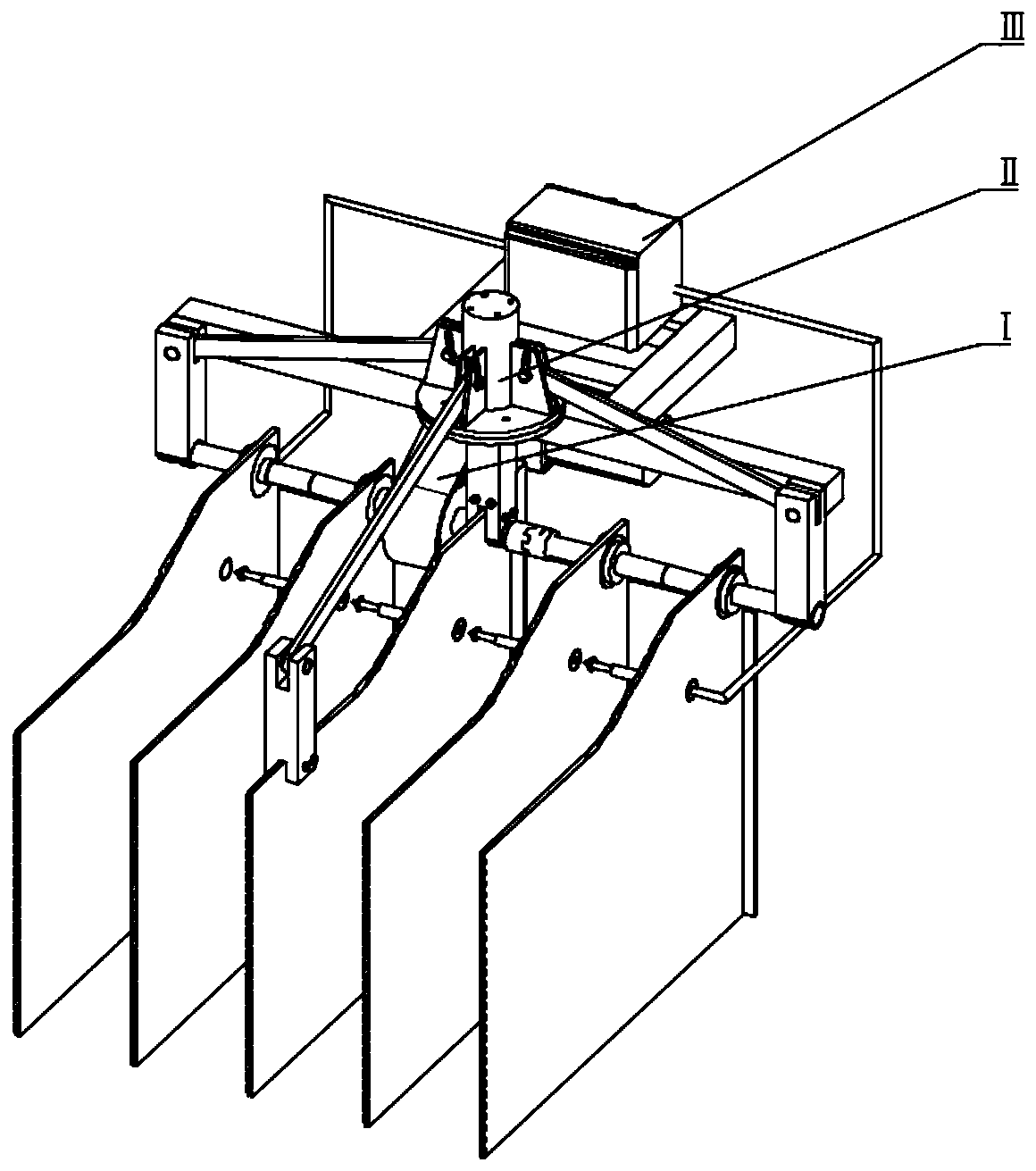

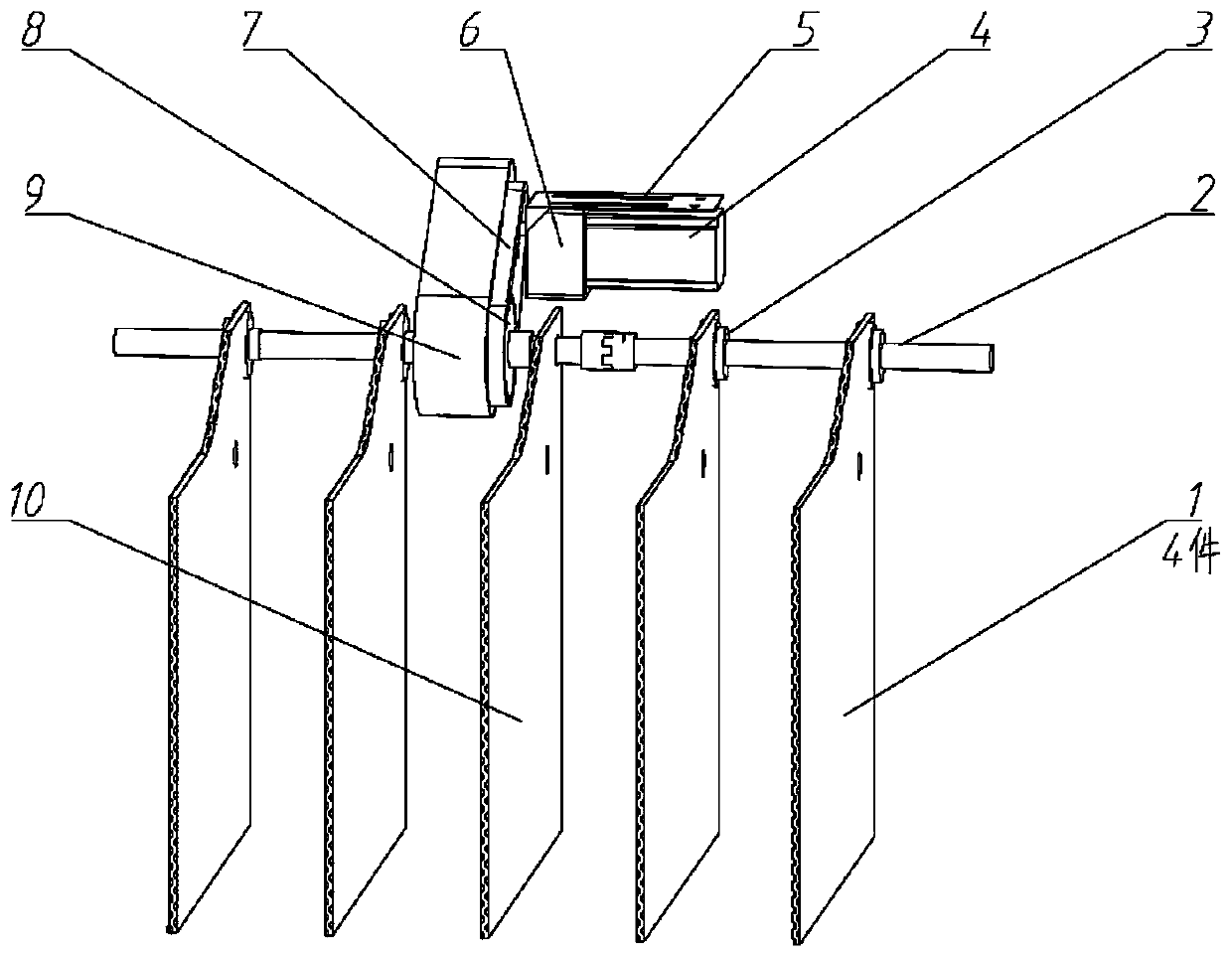

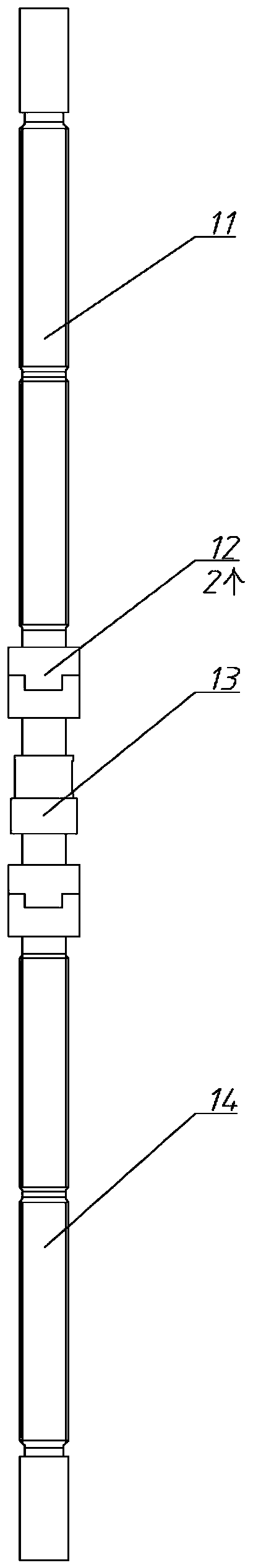

[0030] Embodiment 1: as Figure 1-15 As shown, an automatic palletizing fixture includes a clamping transmission device I, a fixing device II and a feedback device III; wherein, the clamping transmission device I is used to clamp and fix the items to be stacked according to the drive of the feedback device III The device II is used to fix the clamping transmission device I and the feedback device III, and the feedback device III is used to collect the quantity of items to be palletized and drive the clamping transmission device I to move.

[0031] Further, it can be provided that the clamping transmission device I is connected to the fixing device II through bolts, and is connected to the left and right hangers 33 on the fixing device II through the boom bearing 27; the feedback device III is connected to the fixing device II through threads.

[0032] Further, it can be set that the clamping transmission device I includes a movable clip 1, a clamping screw 2, a screw nut 3, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com