A temperature-sensitive ceramic with heat-resisting and cold-avoiding functions, its production method and application

A production method and functional technology, which can be used in applications, clay products, household appliances, etc., can solve the problems of limited application range, insufficient compactness, low strength, etc., and achieve good heat and cold resistance, meet load, and excellent The effect of physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Example 1: Porcelain temperature-sensing ceramics with the function of resisting heat and avoiding cold

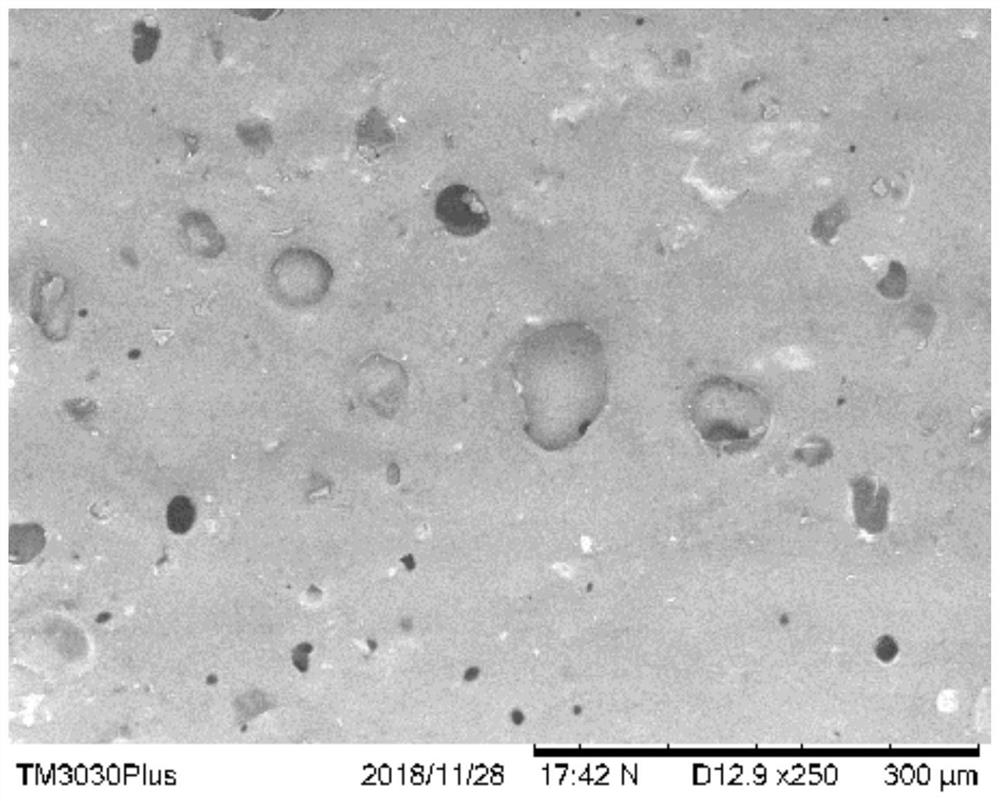

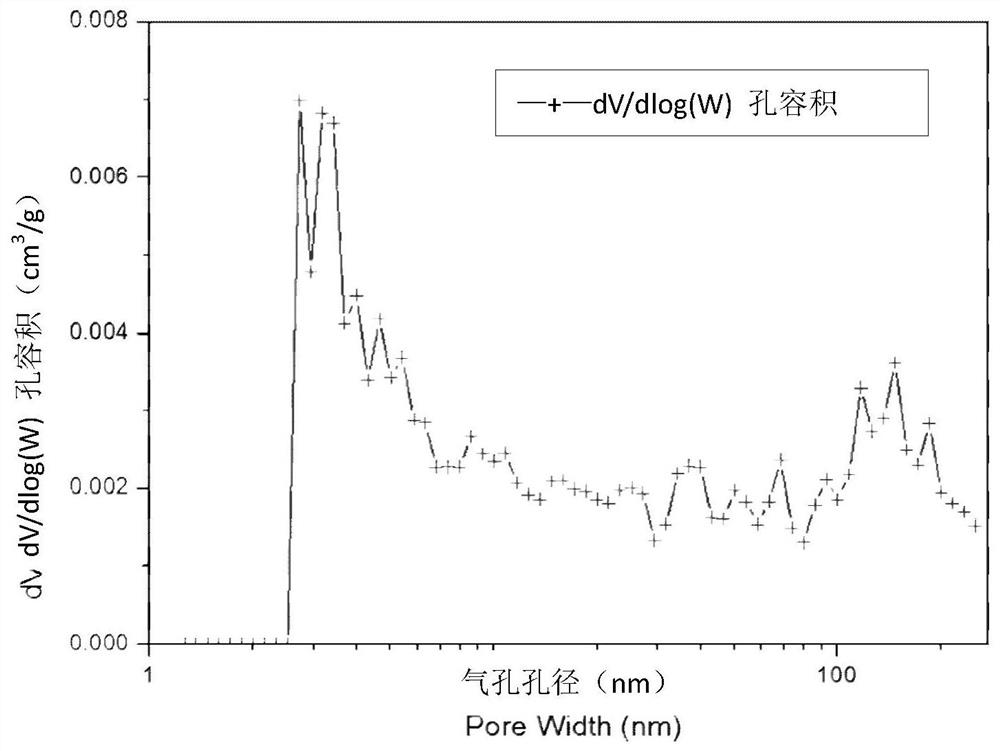

[0064] A porcelain temperature-sensing ceramic with functions of resisting heat and cold, comprising a conventional ceramic body layer, a functional layer compounded on the surface of the conventional ceramic body layer with functions of resisting heat and cold, and a decorative layer compounded on the surface of the functional layer; The functional layer is a ceramic glaze layer with a porous structure; the pores of the porous structure are micro closed pores; the temperature-sensitive ceramics have physical and chemical properties consistent with those of the existing ceramics without the functional layer.

[0065] The functional layer includes the following components in parts by weight: 30 parts of ceramic waste powder, 10 parts of stone waste powder, 45 parts of feldspar, 10 parts of kaolin, 5 parts of quartz and 0.2 parts of quartz pore former.

[0066] The p...

Embodiment 2

[0070] Example 2: A stoneware-like temperature-sensing ceramic with the function of resisting heat and avoiding cold

[0071] A stoneware porcelain temperature-sensing ceramic with heat resistance and cold avoidance functions, comprising a conventional stoneware porcelain ceramic body layer, a functional layer with heat resistance and cold avoidance functions compounded on the surface of the conventional ceramic body layer, and a functional layer compounded on the surface of the functional layer The functional layer is a ceramic glaze layer with a porous structure; the pores of the porous structure are micro closed pores; the physical properties and chemical properties of the temperature-sensitive ceramics are consistent with those of the existing ceramics without the functional layer applied .

[0072] The functional layer comprises the following components in parts by weight: 40 parts of ceramic waste powder, 10 parts of stone waste powder, 30 parts of feldspar, 12 parts of ka...

Embodiment 3

[0077] Embodiment 3: A kind of fine stoneware temperature-sensing ceramics with the function of resisting heat and avoiding cold

[0078] A fine stoneware temperature-sensing ceramic with heat resistance and cold avoidance function, comprising a conventional fine stoneware ceramic body layer, a functional layer with heat resistance and cold avoidance function compounded on the surface of the conventional ceramic body layer, and a functional layer compounded on the surface of the functional layer The functional layer is a ceramic glaze layer with a porous structure; the pores of the porous structure are micro closed pores; the physical properties and chemical properties of the temperature-sensitive ceramics are consistent with those of the existing ceramics without the functional layer applied .

[0079] The functional layer includes the following components in parts by weight: 30 parts of ceramic waste powder, 15 parts of stone waste powder, 30 parts of feldspar, 12 parts of k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com