Pretreatment method for improving natural aging stability of 6000 series aluminum alloy material

A technology of aluminum alloy materials and natural aging, which is applied in the field of pretreatment of aluminum alloy materials, can solve the problems of high cost, achieve the effects of increasing stamping yield, reducing production costs, and prolonging the retention time of bake hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

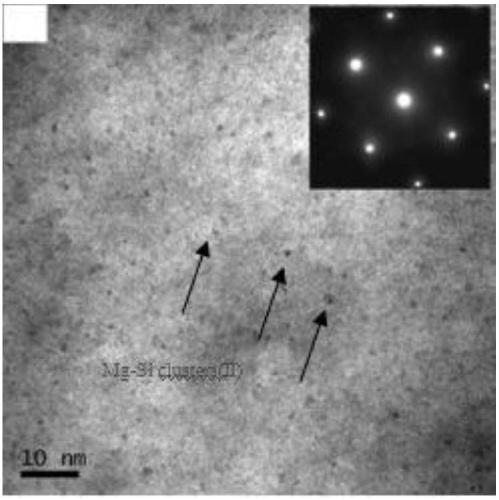

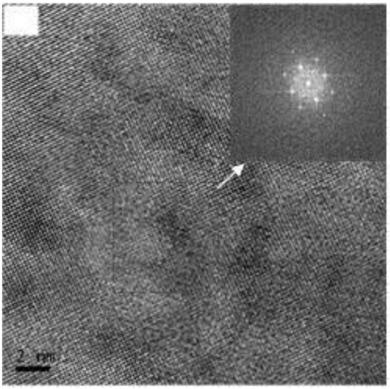

Image

Examples

Embodiment 1-6 and comparative example 1

[0037] In the various embodiments and comparative examples of this case, the 6000 series aluminum alloy ingot is subjected to homogenization heat treatment, hot-rolled and cold-rolled into a cold-rolled plate with a thickness of 1mm, and then it is subjected to the pretreatment shown in each embodiment and comparative example. Process, preprocessing steps include (the specific parameters of each embodiment and comparative example are listed in Table 2):

[0038] (1) Solution quenching treatment: solid solution for 10-50 minutes, the solution temperature is 500-560°C, and then cooled to room temperature at a cooling rate of 30-150°C / s, and the cooling method is water cooling;

[0039] (2) Low-temperature pre-aging treatment within 24 hours: control the temperature at 50-70°C and keep warm for 0-72 hours;

[0040] (3) Pre-stretch deformation within 24 hours: the deformation amount is 2-5%;

[0041](4) Perform high-temperature pre-aging treatment within 168 hours: control the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com