Parking brake device for rail transit vehicle and manual mitigation method thereof

A rail transit vehicle, parking braking technology, applied in the direction of brake actuators, gear transmission mechanisms, mechanical equipment, etc., can solve the problems of many parts, high processing and assembly requirements, complex structure, etc., and achieve high reliability and durability High performance, convenient engineering operation, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

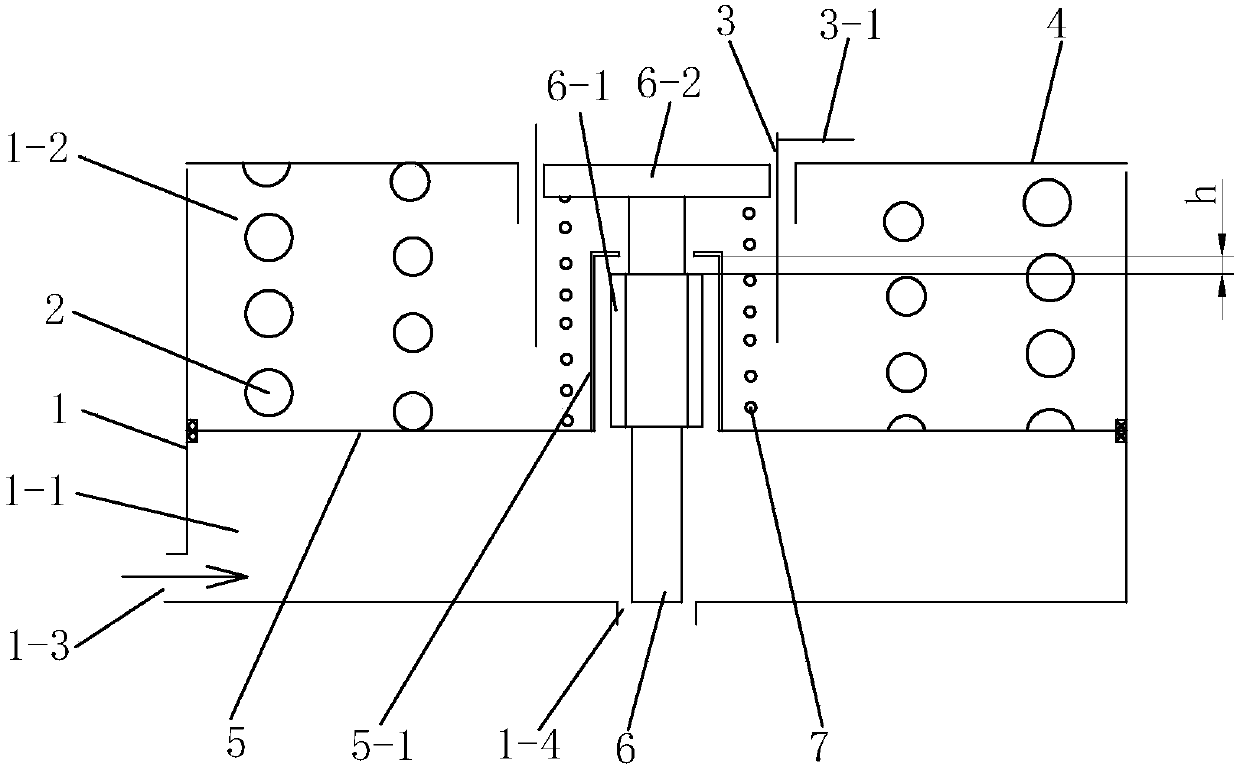

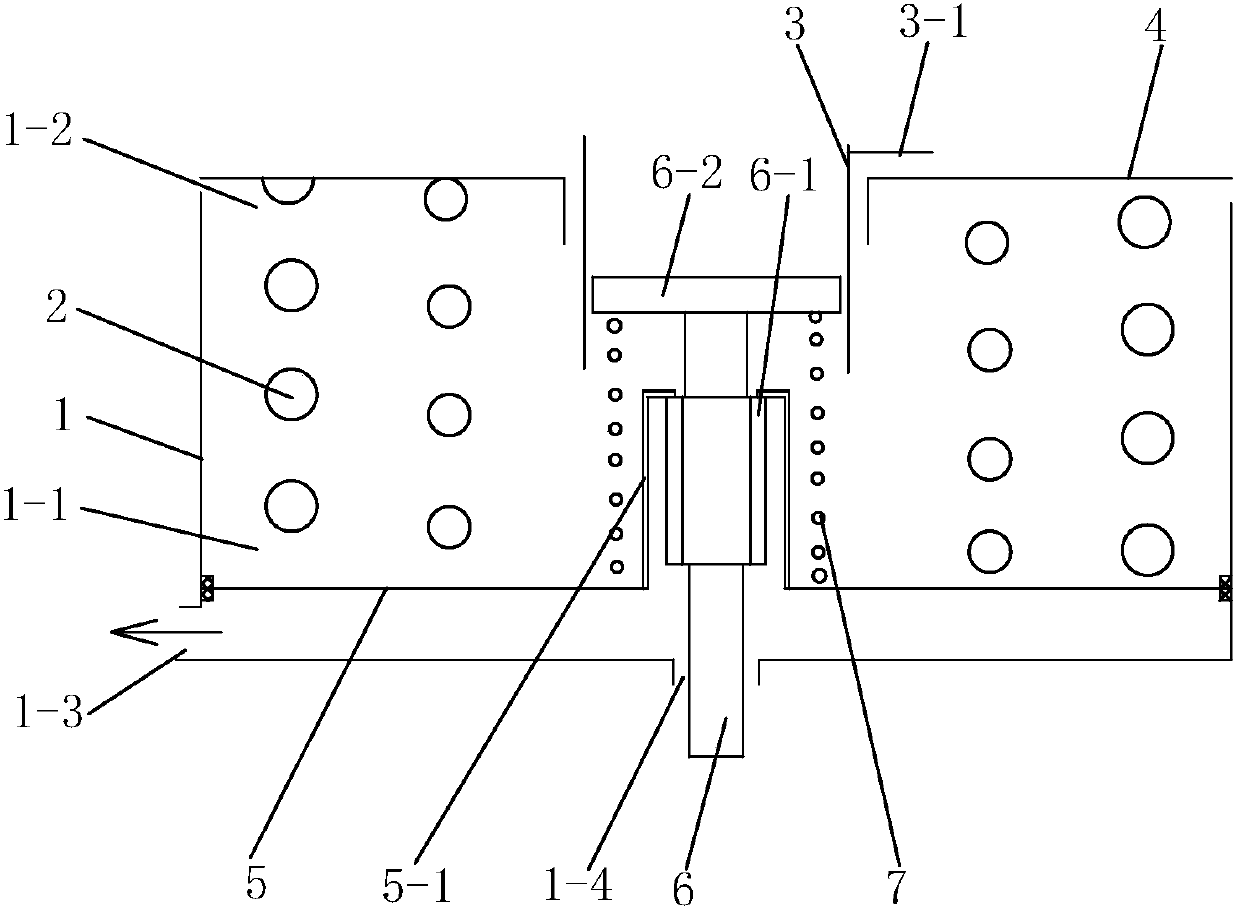

[0037] See Figure 1 to Figure 14 , this embodiment includes a cylinder body 1, a cylinder head 4, a parking piston 5 and a brake lever 6, the parking piston 5 divides the cylinder cavity into a first cavity 1-1 below and a second cavity 1-2 above, Corresponding to the first chamber 1-1, the cylinder body 1 is provided with an air inlet 1-3 and a brake lever outlet 1-4, and a parking spring 2 is arranged in the second chamber 1-2, and the upper end of the parking spring 2 is in contact with the cylinder. Cover 4 is offset, and the lower end is offset with parking piston 5 .

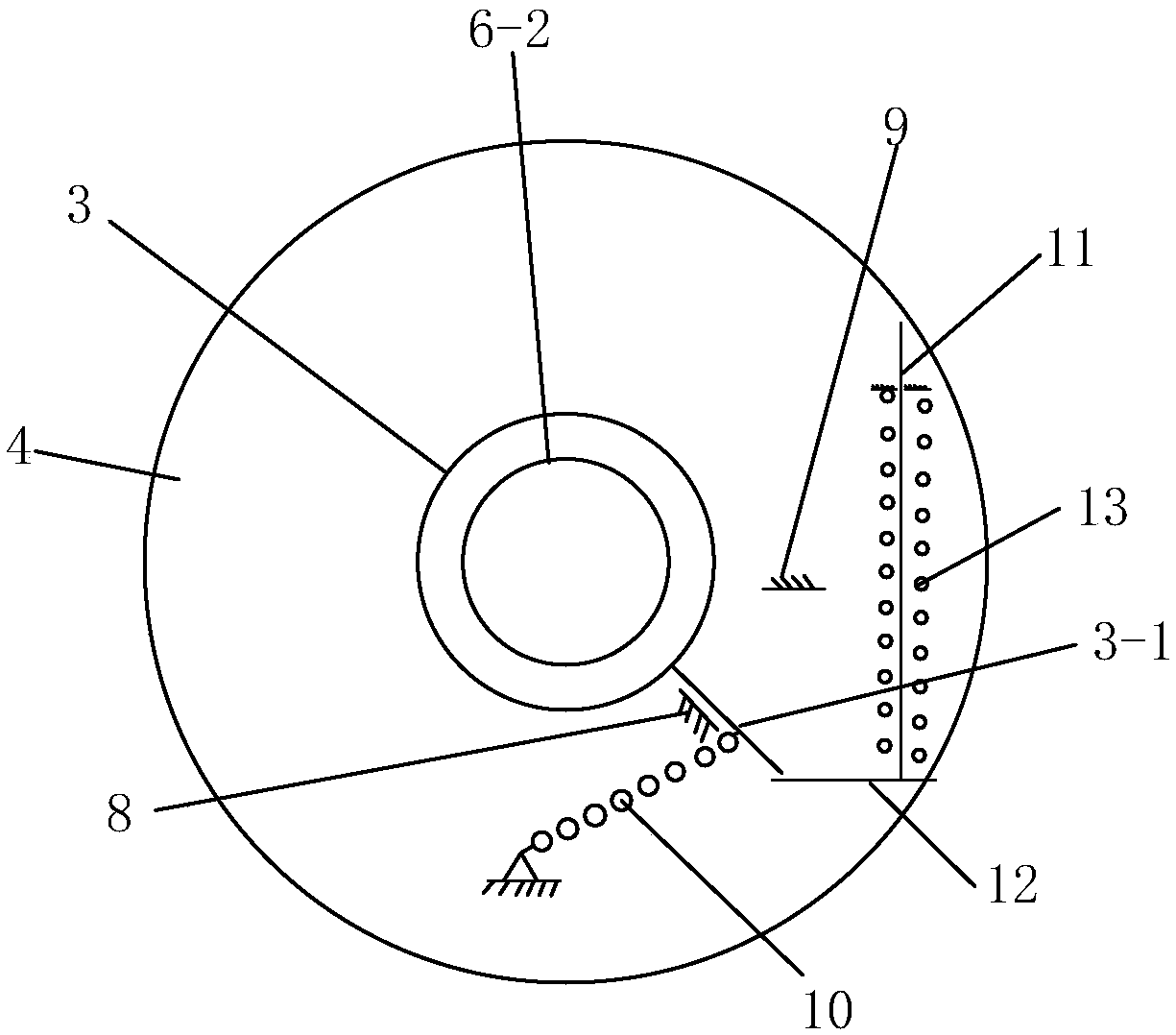

[0038] The center of the parking piston 5 is provided with an upwardly protruding limit cover 5-1, the middle part of the brake lever 6 is provided with a spline body 6-1, and the teeth of the spline body 6-1 of the brake lever 6 There are at least 4 teeth. In the accompanying drawings, the spline body 6-1 of the brake lever 6 has 6 teeth, and the tooth ends are arc-shaped. The top of the limit cover 5-...

Embodiment 2

[0046] Figure 15 and Figure 16 As shown, the spline body 6-1 of the brake lever 6 in this embodiment is provided with 12 teeth, and the top of the piston limit cover 5-1 is provided with 12 teeth that match the spline body 6-1 of the brake lever 6. A spline groove 5-1a. See embodiment 1 for others.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com