A bilateral flat permanent magnet linear motor

A permanent magnet linear motor, flat-plate technology, applied in electromechanical devices, electrical components, electric components, etc., can solve the problems of low thrust density and low acceleration, and achieve the effects of improving reliability, improving utilization, and easy fault-tolerant control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

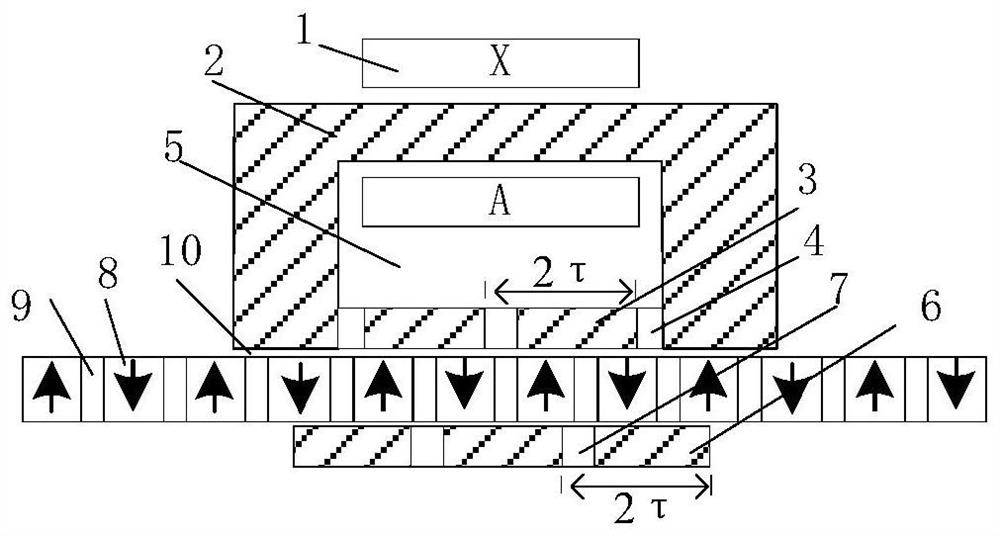

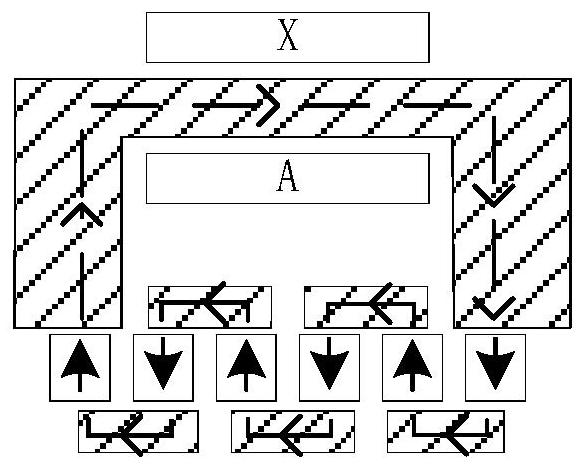

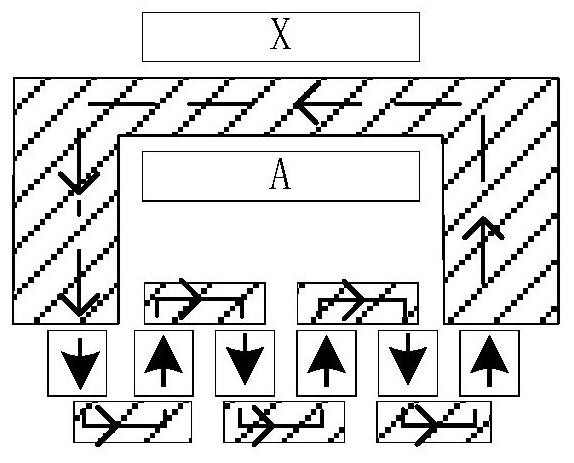

[0023] Such as figure 1 As shown, this embodiment is a single-phase motor, including primary, secondary and two air gaps. The upper primary is composed of an armature winding (1), a permeable core (2), an array of slotted permeable cores (3) and a gap (4) between the permeable cores. The permeable core (2) has an annular opening structure, and a large open slot (5) structure is formed inside, and the armature winding (1) is arranged in the slot, and is wound on the yoke of the permeable core (1). An array of permeable magnetic cores (3) is arranged in the notch along the horizontal direction. The distance between the magnetically permeable cores (3) in the array is 2τ, with a gap (4) in the middle. The lower primary is composed of permeable cores (6) with a salient pole structure and gaps (7), and the distance between adjacent permeable cores (6) is 2τ. The midpoint of the upper primary notch permeable core (3) corresponds to the midpoint of the lower primary gap (9). Cons...

Embodiment approach 2

[0028] Such as Figure 4 As shown, the difference between this embodiment and the first embodiment is that the first embodiment is a single-phase motor, and the third embodiment is a three-phase motor. This embodiment is a three-phase motor. The structures of the B-phase motor and the C-phase motor are exactly the same as that of the A-phase motor. It is (k±2 / 3)τ, K is a natural number. The winding adopts three-phase power supply, which can be sine wave or square wave power supply. The motor adopts a modular design, there is no electrical coupling between the phases, and the magnetic coupling is very small. When a winding failure of a certain phase does not affect other phases, it is easy to implement fault-tolerant control and is conducive to improving the reliability of the motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com