Feeding method and system of surface mounting machine

A technology of placement machine and feeding, applied in the direction of electrical components, electrical components, etc., can solve the problems of increasing control pins, complex circuit of placement machine feeding system, high cost, reducing usage, simple and practical structure, accurate The effect of feeding operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] refer to Figure 1 ~ Figure 4 , a feeding method for a placement machine, comprising the following steps:

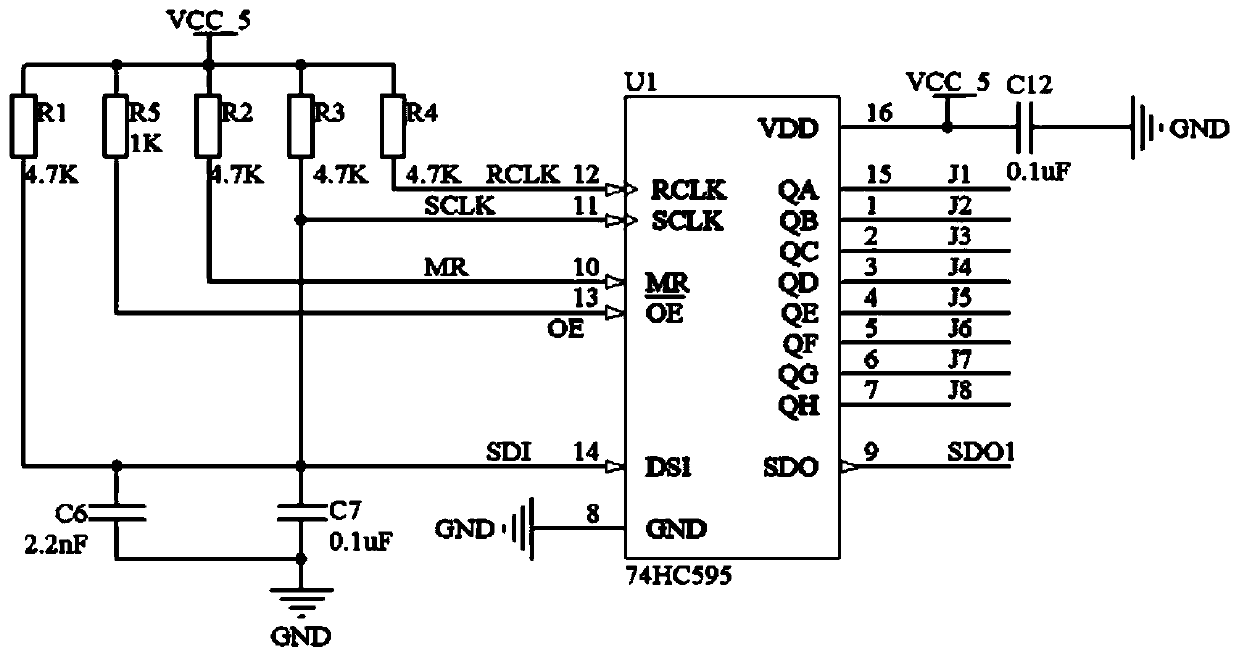

[0026] 1) Enable the 74HC595 chip, and move the bit data to be input into the 74HC595 data input terminal;

[0027] 2) The bit data is moved into the chip bit by bit. The bit controller sends the low bit first and then the high bit at the chip data input pin, that is, pin 11. After a rising edge is generated, the data on the serial data input pin SDI is moved into the 74HC595 In the shift register, if there is cascading, serial input can be performed;

[0028] 3) Output data in parallel, the bit controller sends the rising edge signal to the output memory latch pin of the chip, and sends the data on the serial data input pin SDI to the output latch;

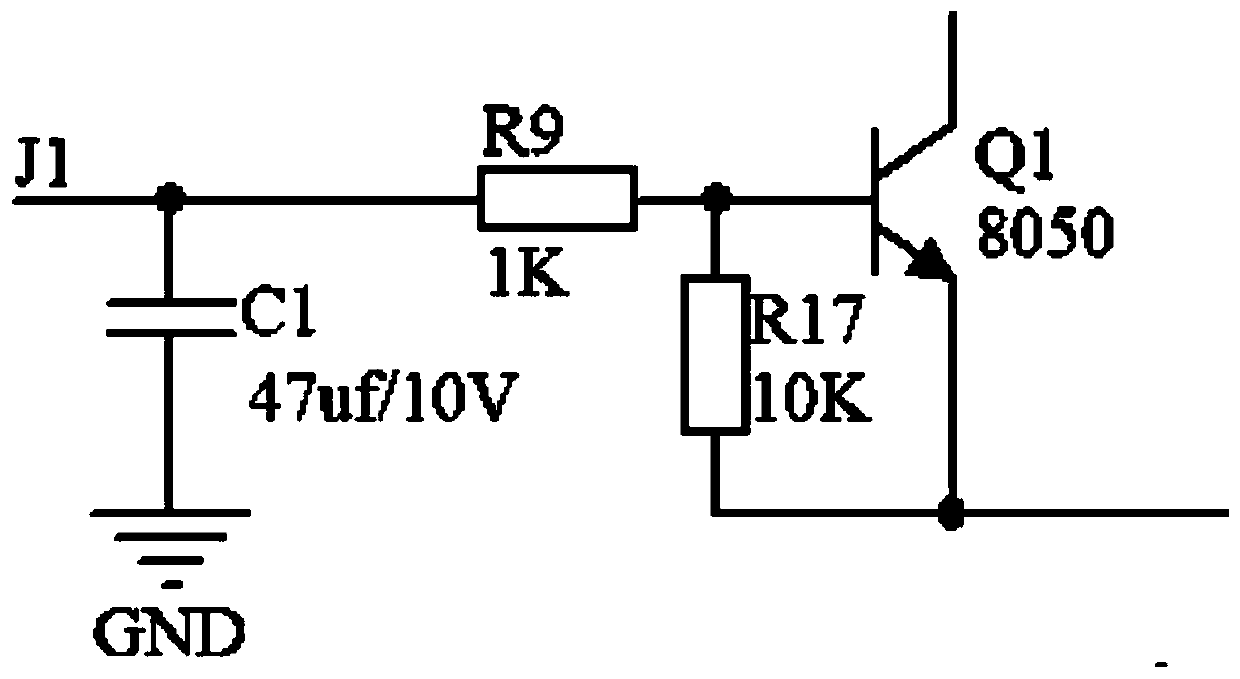

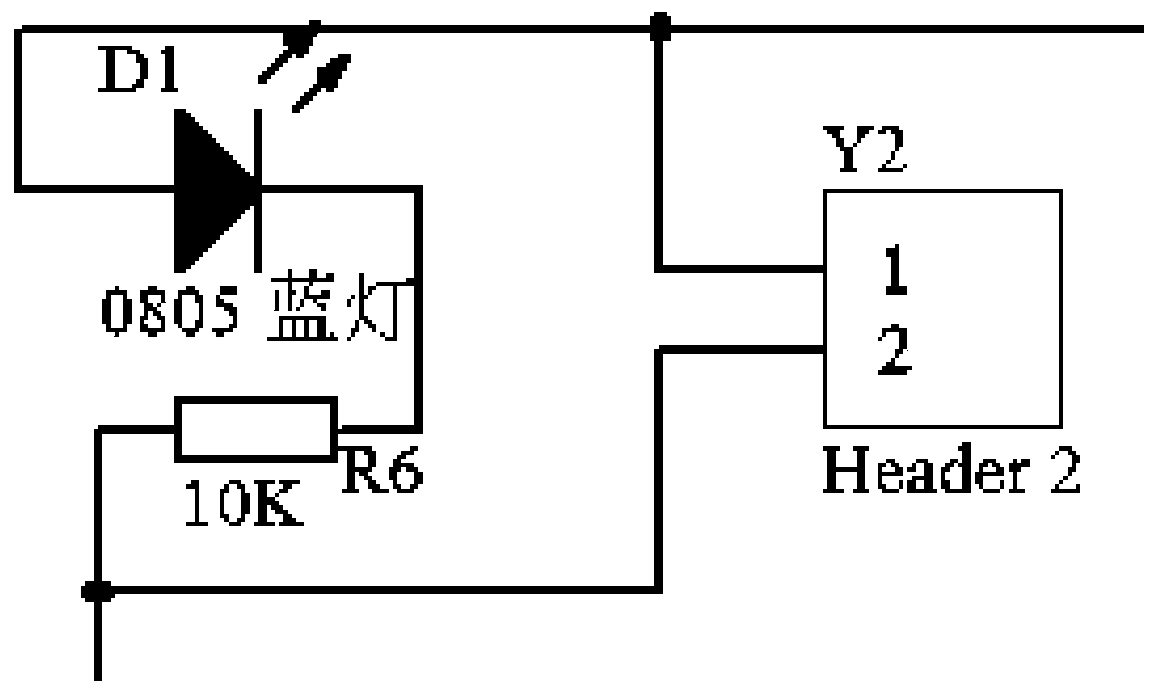

[0029] 4) After the data is sent in, input a high level to the chip enable pin OE, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com