High-voltage switching device and switching system having a high-voltage switching device and method for producing a high-voltage switching device

A high-voltage switch and switch technology, which is applied in the field of switchgear and high-voltage switchgear, can solve the problems of large space and long insulation distance, and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

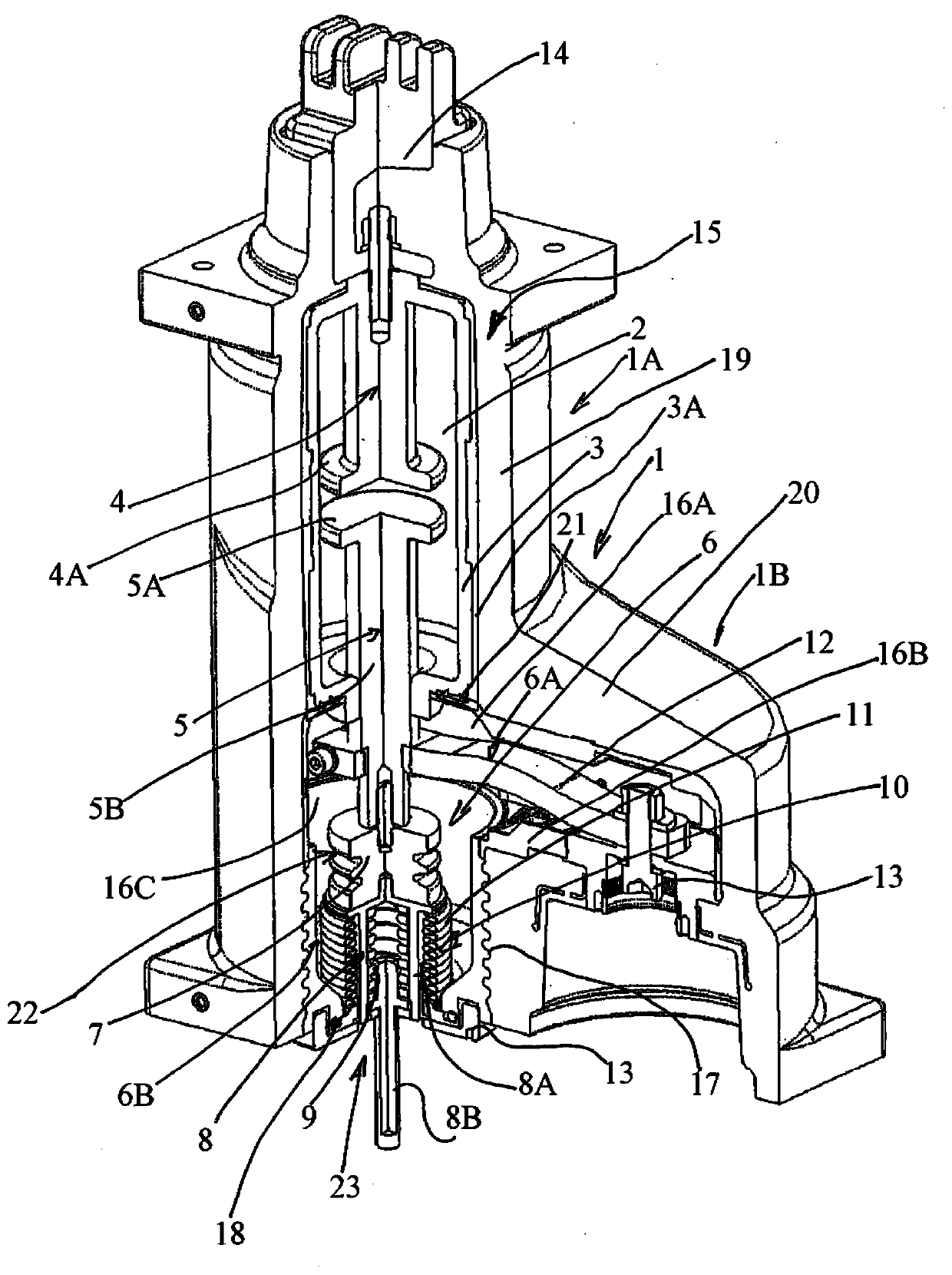

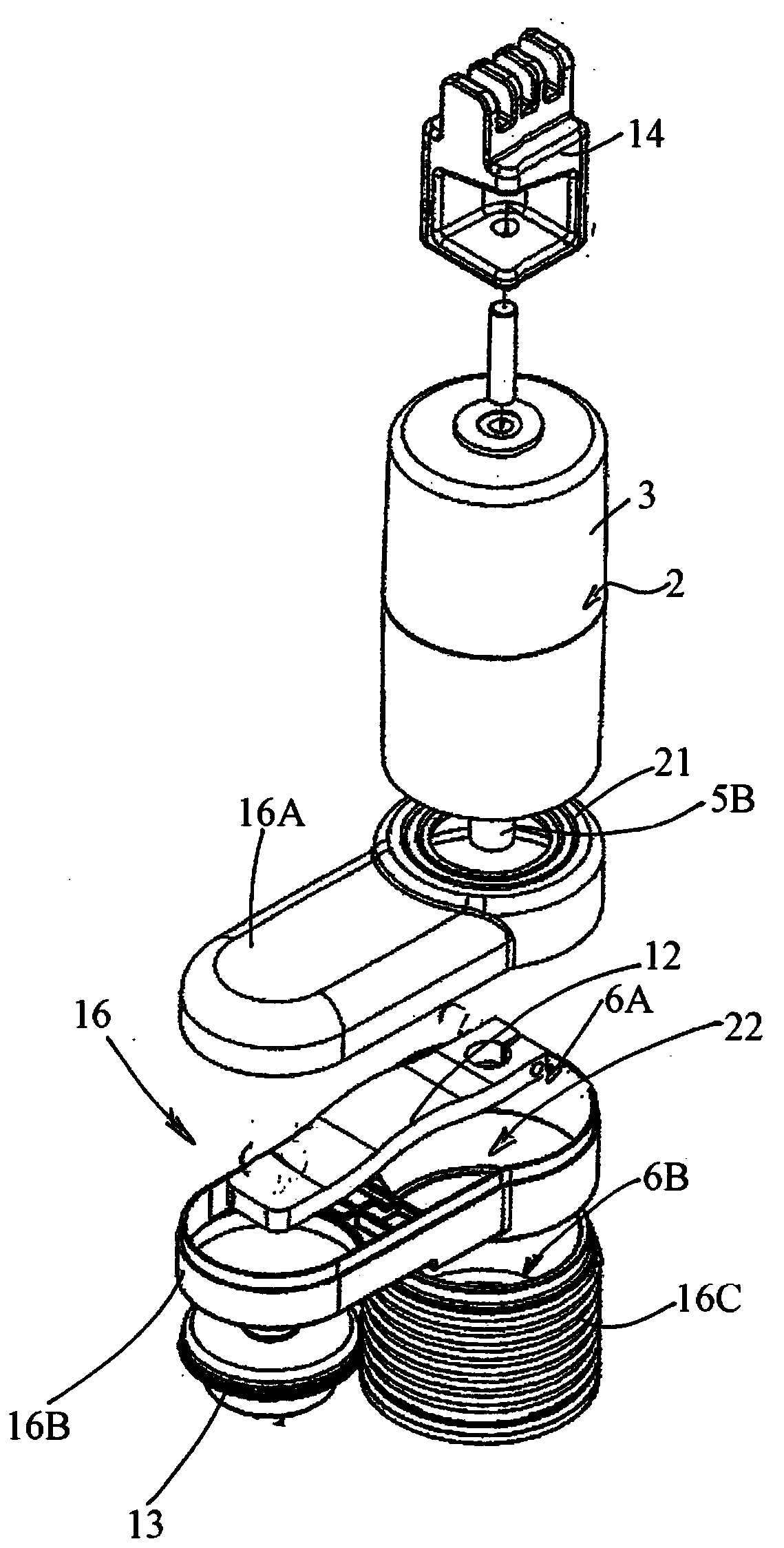

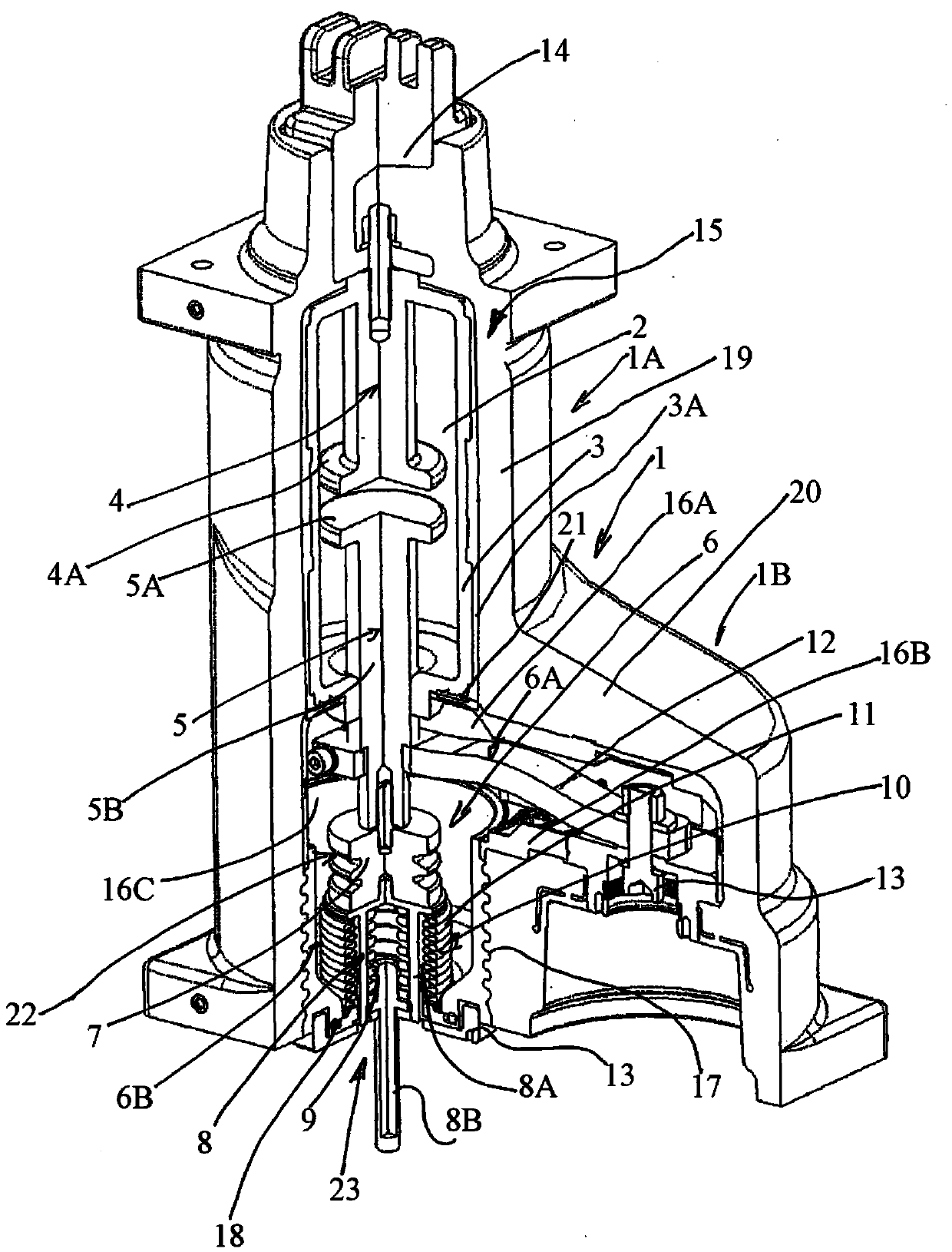

[0029] figure 1 The components of the high voltage switchgear that are critical to the invention are shown, while figure 2 Only the individual components of the switching device are shown in an exploded perspective view. Mutually corresponding parts have the same reference numerals in the figures.

[0030] The high-voltage switchgear has a housing 1 comprising several parts or components, which in the normal installed position has an upper half-housing 1A and a lower half-housing 1B. Inside the upper half-housing 1A there is a vacuum switching chamber 2 with a cylindrical housing 3 which accommodates a fixed upper switching contact element 4 and a movable lower switching contact element 5 . The two switching contact elements 4 , 5 have disc contacts 4A, 5A which are located in the housing 3 of the vacuum switching chamber 2 . The closing and opening of the contacts 4A, 5A can close or interrupt the current path, that is, switch the load current and the short-circuit curren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com