Manufacturing method of counterweight block easy to weld

A manufacturing method and technology for weights, which are applied to rackets, golf clubs, golf balls, etc., can solve the problems of limiting the effective application of welded weights, the color difference between the welding surface and the ball head body, etc., so as to save mold development and cost. The cost of consumption, the effect of ensuring firmness and accuracy, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

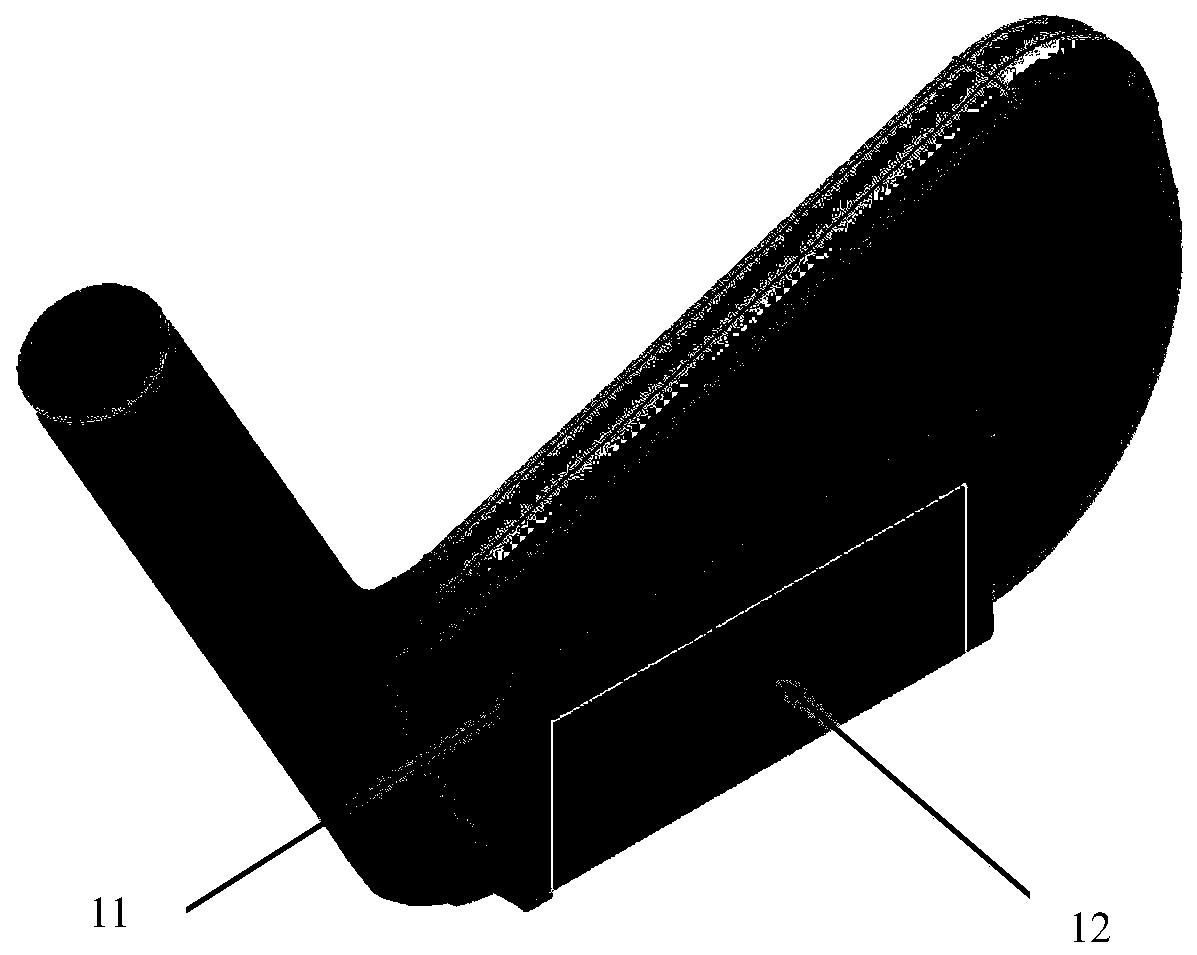

[0040] like Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 and Figure 9 Shown, the manufacture method of easy-to-weld counterweight of the present invention comprises steps:

[0041] A1. Select a metal material or alloy material with a melting point similar to that of the golf head material, and use the metal material or alloy material to cast the outer thin shell of the counterweight;

[0042] A2, the outer thin shell is filled with tungsten-based alloy;

[0043] A3. Sintering the outer thin shell and the tungsten-based alloy in a vacuum furnace.

[0044] According to an embodiment of the present invention, the step A1 includes the step of: selecting 17-4PH stainless steel, precision casting the outer thin shell at a furnace temperature of 1650°C and a shell temperature of 1250°C.

[0045] In another embodiment of the present invention, the step A1 includes the step of: selecting 304 stainless steel, precision casting the outer thin shell at a furnace temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com