A fully automatic assembly equipment for inductors

It is an assembly equipment and fully automatic technology, which is applied in mechanical equipment, metal processing equipment, and devices for coating liquid on the surface. It can solve problems such as condensation at the end of the core, easy overflow of glue, and impact on product quality. The effect of improving quality, reducing scrap rate and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

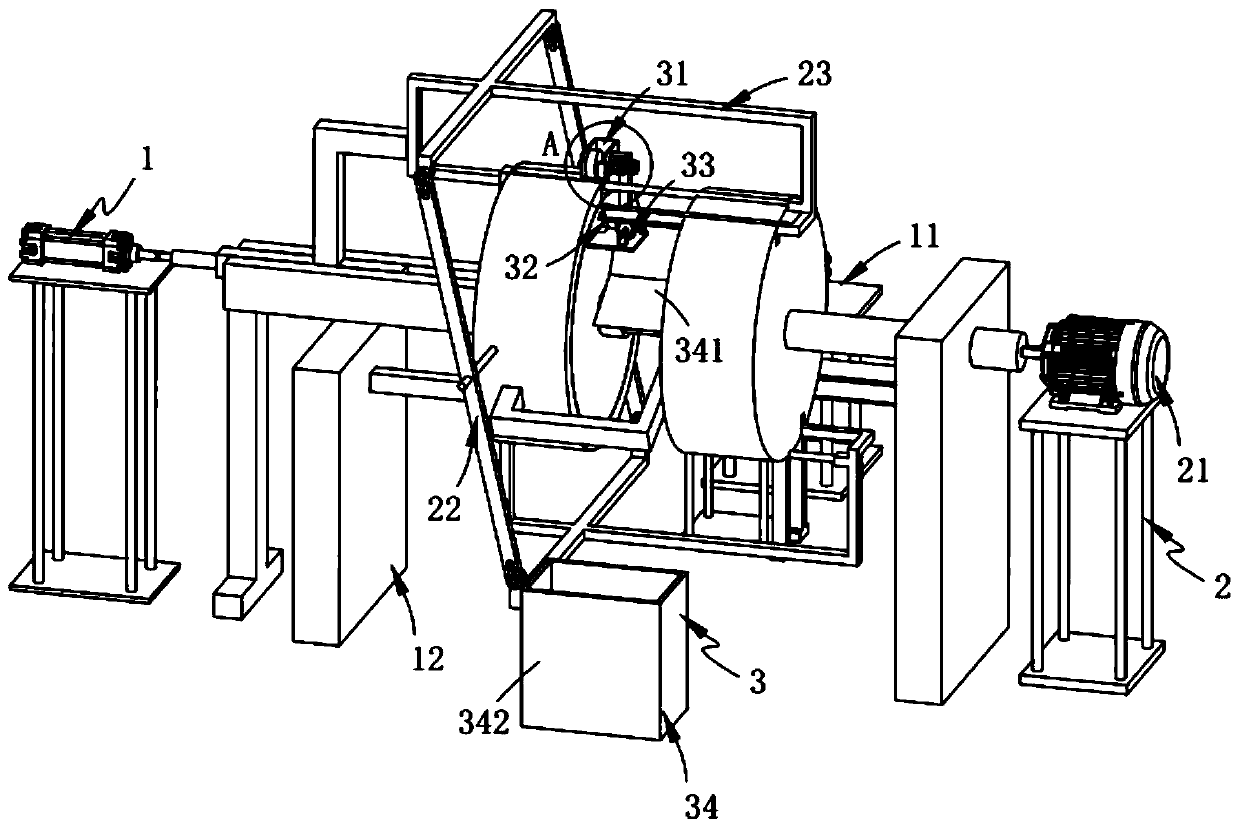

[0070] Such as figure 1 , Figure 11 with Figure 12 As shown, a fully automatic assembly equipment for inductors, including:

[0071] A feeding mechanism 1, the feeding mechanism 1 includes a coil upper assembly 11 and a magnetic core upper assembly 12 arranged perpendicularly to the coil upper assembly 11;

[0072] The station switching mechanism 2, the station switching mechanism 2 includes a rotating assembly 21 rotatably arranged on the magnetic core upper assembly 12, a transmission assembly 22 fixedly arranged on the rotating assembly 21 and symmetrically arranged, and the transmission assembly 22 connected with the transmission a reciprocating assembly 23 that is rotatably connected to the assembly 22 and slides horizontally along said rotating assembly 21; and

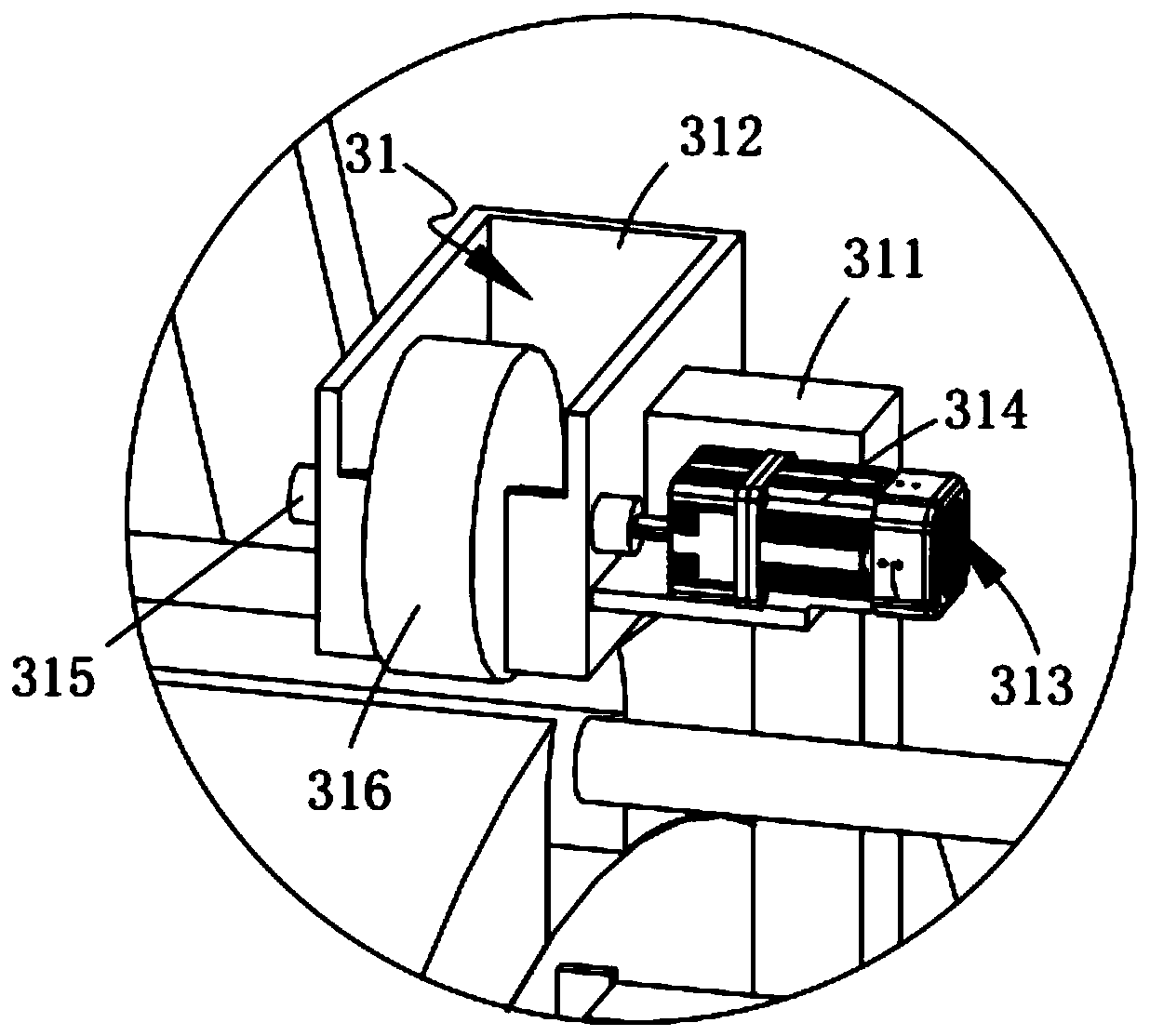

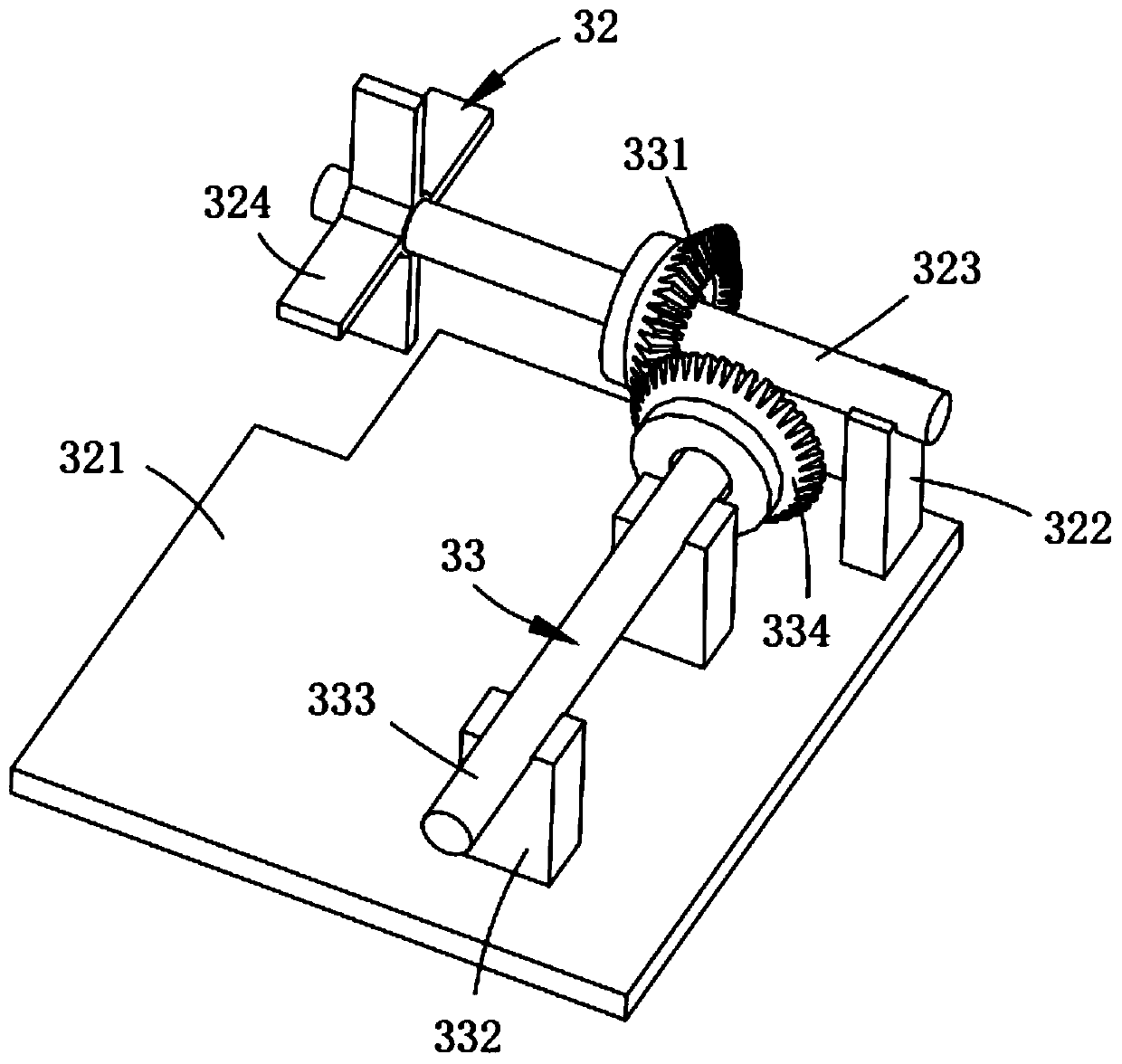

[0073] Forming and assembling mechanism 3, the forming and assembling mechanism 3 includes a gluing assembly 31 fixedly arranged on the magnetic core upper assembly 12 and located above the rotating assembl...

Embodiment 2

[0133] Such as figure 1 As shown, the parts that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below. The difference between this embodiment two and embodiment one is:

[0134] further, such as figure 1 As shown, the discharge plate 341 is arranged obliquely downward.

[0135] In this embodiment, by setting the output assembly 34, the fully assembled inductance coil is discharged to the material receiving bucket 342 in time along the inclined downwardly disposed discharge plate 341 for storage, and the whole device is continuous and complete.

[0136] work process:

[0137] First put the coils on the conveyor belt 1114 in turn, the coils are pushed onto the push plate 1123, start the cylinder a1121, and the coils are pushed to the front of the receiving shaft b2324; at this time, put the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com