Polishing equipment for end socket

A technology of equipment and grinding wheels, applied in grinding/polishing equipment, metal processing equipment, machine tools suitable for grinding workpiece edges, etc., can solve the problems of uneven grinding, long processing time, raised incision, etc. Structure, solve the effect of inaccurate grinding and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

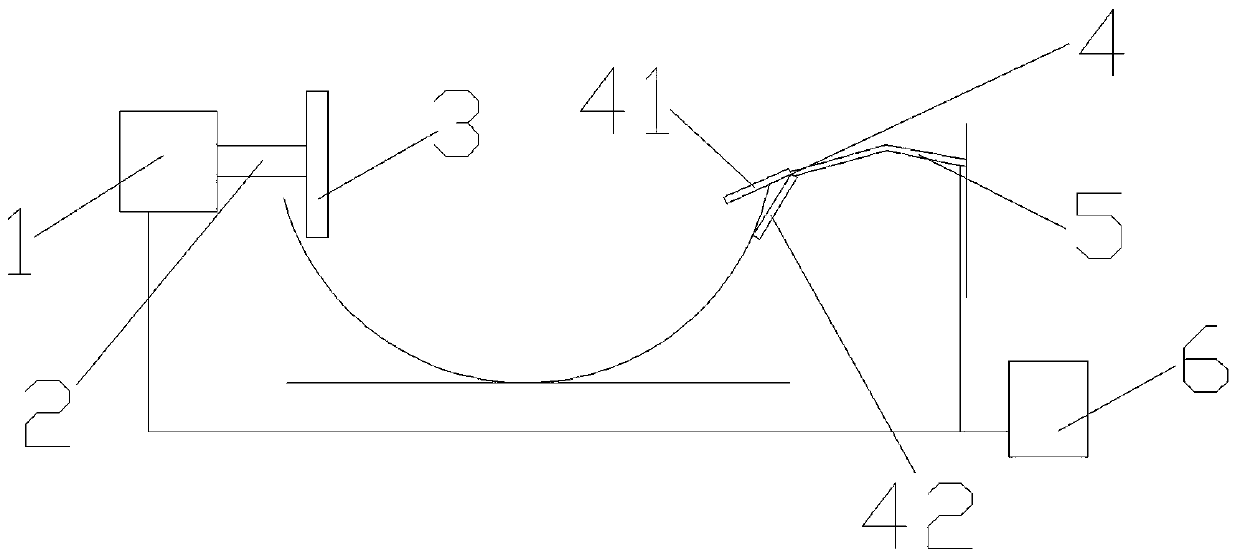

[0008] Embodiment: A kind of grinding equipment for sealing heads, including a driving device 1, a driving shaft 2, a grinding wheel 3, and a movable caliper 4; the driving device 1 is connected to the driving shaft 2, and the driving shaft 2 is connected to the grinding wheel 3; the movable caliper 4. Connect the hydraulic support 5. The movable caliper 4 includes a first caliper clip 41 and a second caliper clip 42 and is arranged on the same bearing. The clamping surfaces of the first caliper clip 41 and the second caliper clip 42 are made of rubber.

[0009] The driving device 1 and the movable caliper 4 are connected to the controller 6 at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com