A kind of inverted separation bucket type material spreading device

A material spreading device and a separation type technology, which is applied in the field of flip-chip separation type barrel type material spreading device to achieve the effects of reduced workload, simple mechanism structure, and easy maintenance and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

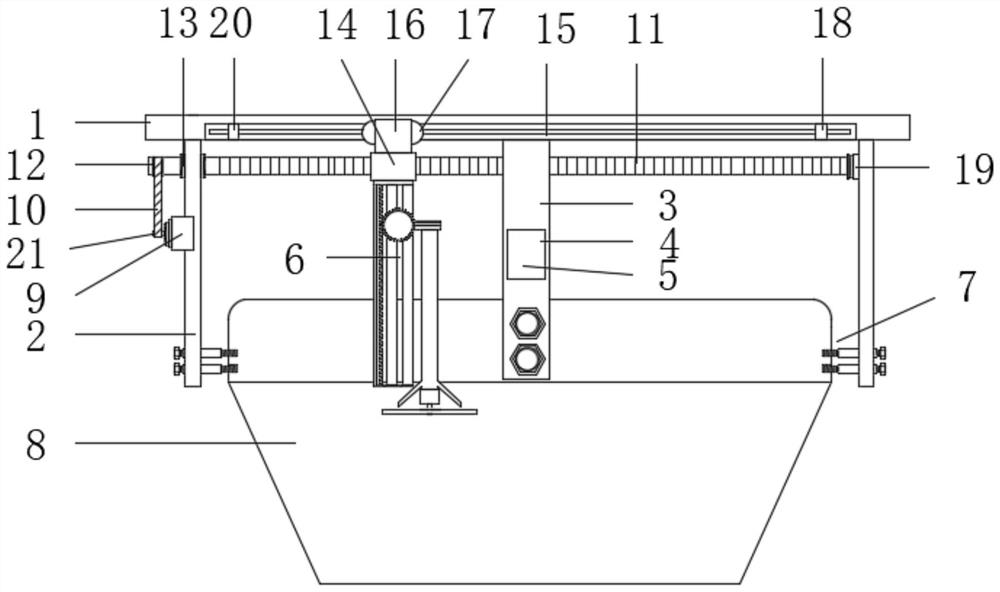

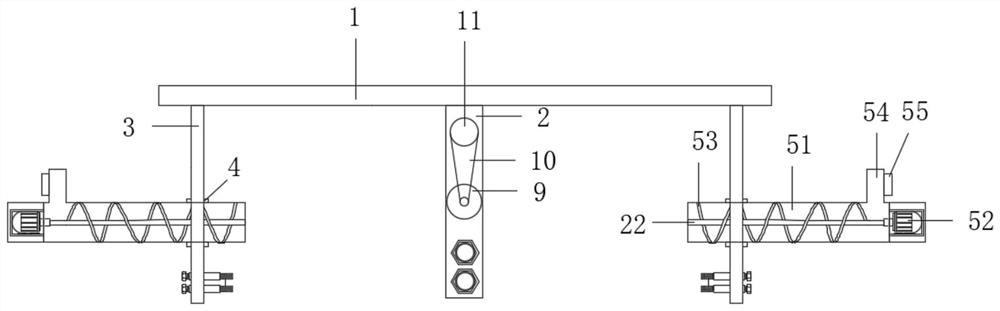

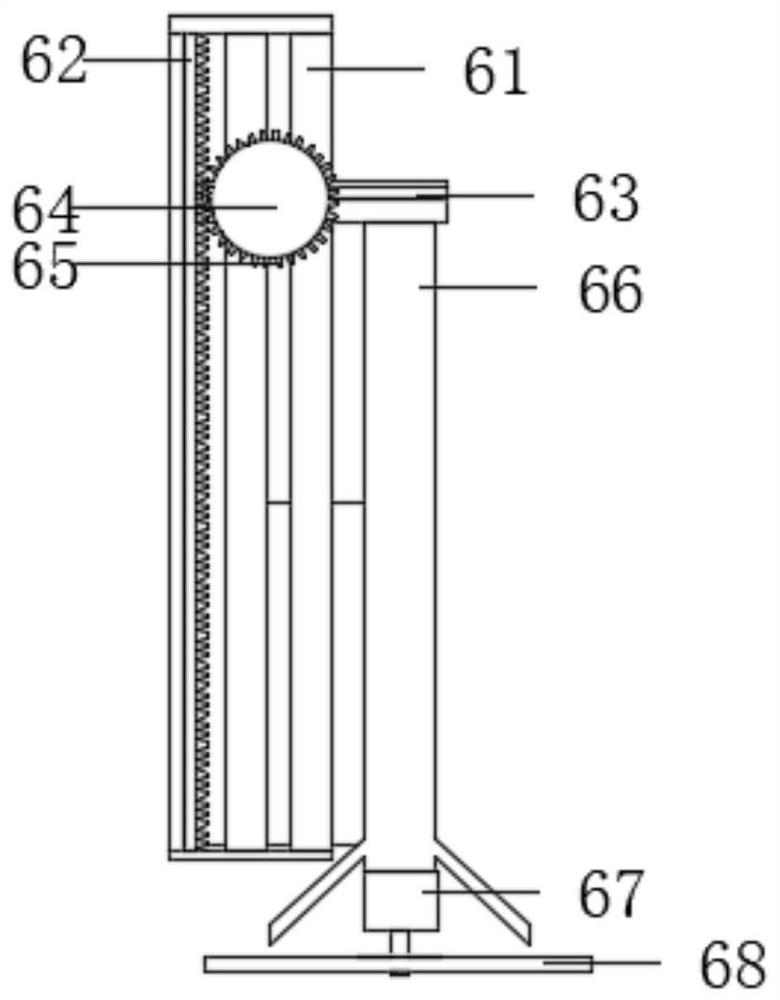

[0024] Such as Figure 1-4 As shown, this specific embodiment adopts the following technical solutions: an inverted separation bucket type material spreading device, including a cross top frame 1, and the lower end of the cross top frame 1 is respectively connected to a No. 1 fixing frame 2 and a No. 2 fixing frame 3 , the No. 1 fixed frame 2 and the No. 2 fixed frame 3 below are provided with material spreading bucket 8, and the both sides of described No. 1 fixed frame 2 and No. 2 fixed frame 3 are all provided with fixed frame limit mechanism 7, so The No. 1 fixed mount 2 and the No. 2 fixed mount 3 are all connected with the material spreading bucket 8 by the fixed mount limit mechanism 7, and a threaded rod 11 is arranged between the two side walls of the No. 1 fixed mount, and the threaded rod One end of 11 is connected with No. 1 fixed frame 2 through No. 2 bearing 19, and the end of said threaded rod 11 away from No. 2 bearing 19 is connected with No. 1 fixed frame 2 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com