Integrated formwork system for cast-in-place of cantilever window sill in secondary structure and formwork supporting method

A secondary structure and window sill technology, which is applied in the field preparation of building components, formwork/formwork/work frame, building construction, etc., can solve the problems of secondary structure wall damage and low formwork reuse rate , to achieve the effect of easy construction, convenient assembly, and reduced quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with accompanying drawing:

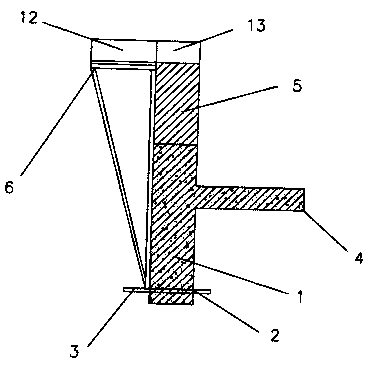

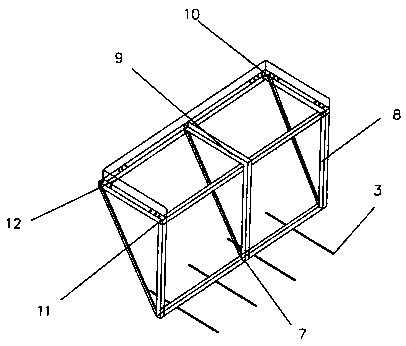

[0020] An integrated formwork system for cast-in-place cantilevered window sills with a secondary structure, including the window openings of the secondary structural wall of this floor, the primary structural concrete floor 4 of this floor and the primary structural concrete wall 1 of the lower floor, and the secondary structural wall of this floor The primary structure concrete wall 1 of the lower layer directly below the window opening of the main body is provided with a reserved hole 2 for the screw, and a screw 3 is arranged in the reserved hole 2 for the screw, and a triangular bracket is provided outside the window opening of the secondary structure wall of this layer 6. The horizontal beam 7 at the bottom of the triangular bracket 6 is crimped on the screw 3, and the inner rectangular vertical frame 8 of the triangular bracket is attached to the secondary structure wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com