Solenoid valve and digester thereof

A technology of solenoid valves and cookers, applied in steam cooking utensils, lifting valves, valve details, etc., can solve the problems of magnetic core and valve core separation failure, low reliability, unsafe use, etc., and achieve simple structure setting and improved reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

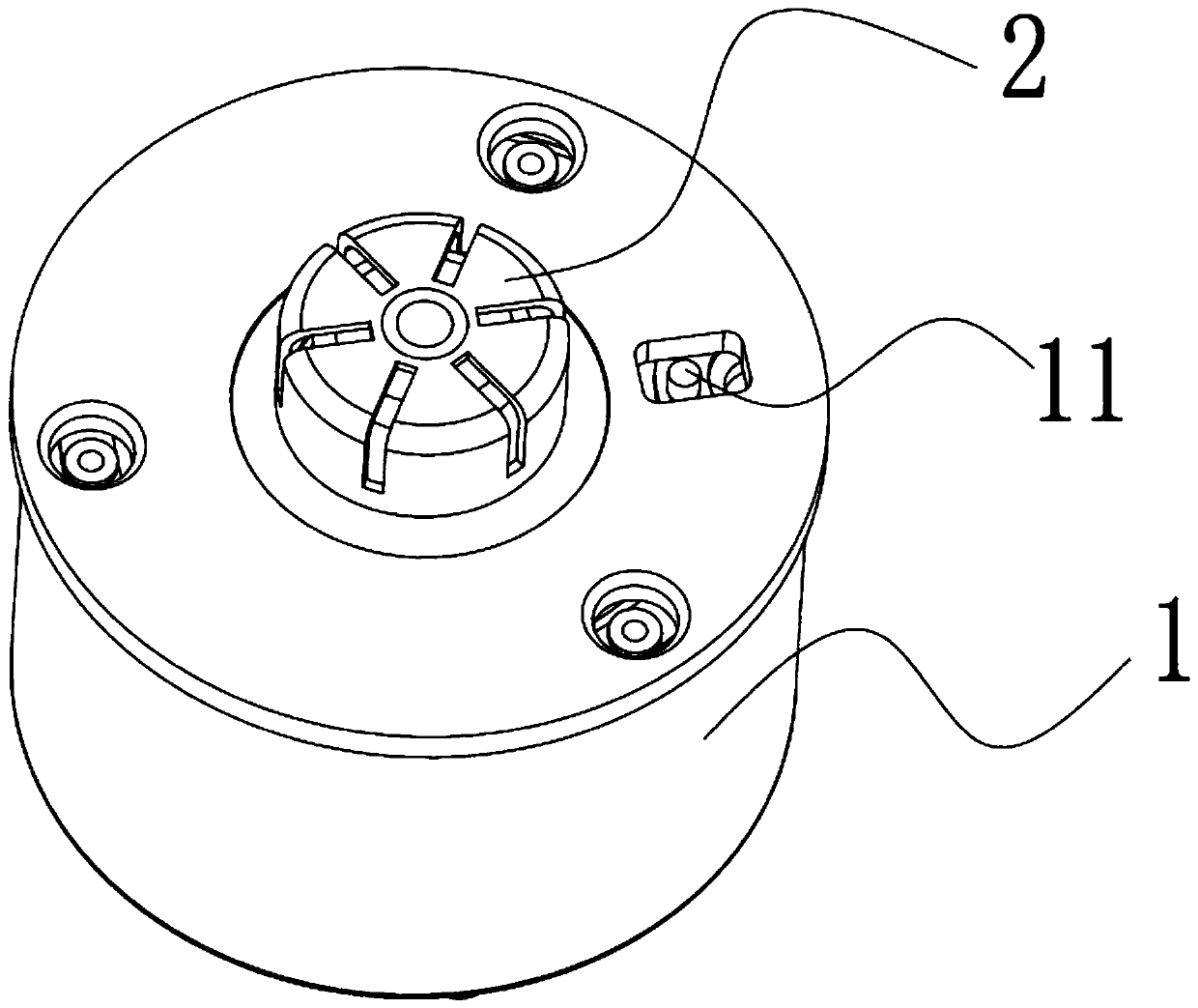

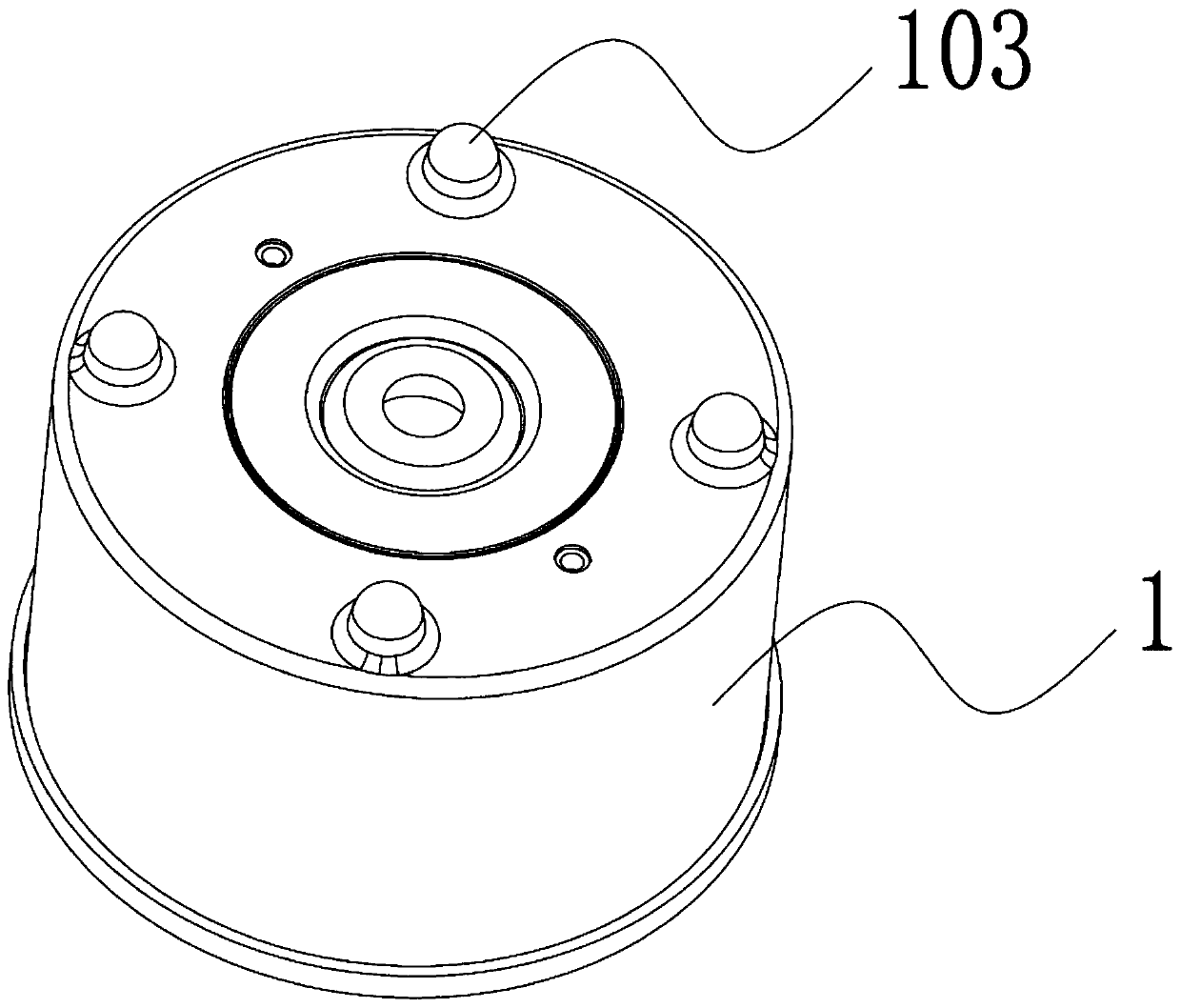

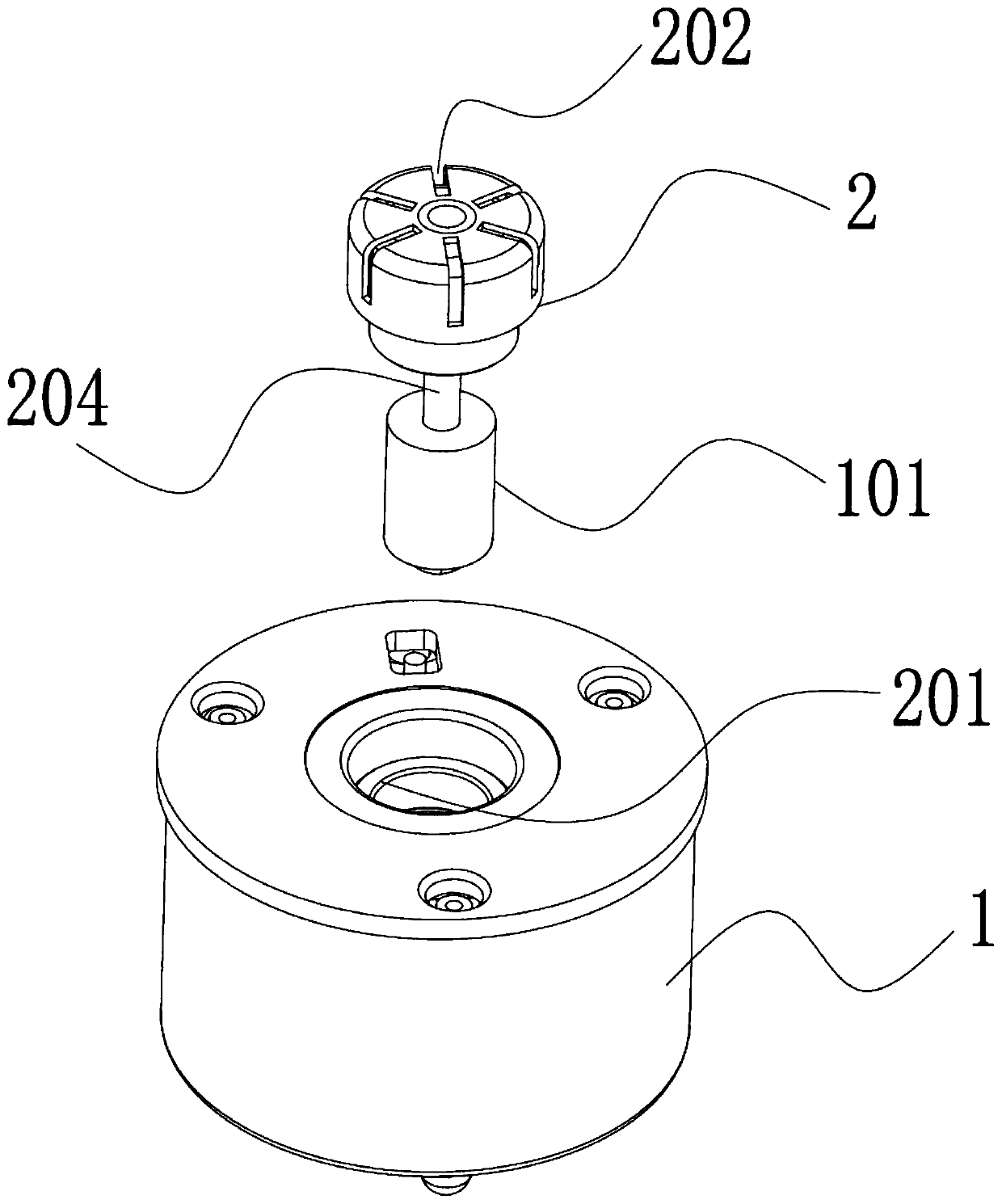

[0049] Embodiment: a kind of electromagnetic valve of the present invention and digester thereof, as Figure 1 to Figure 23As shown in the composition, this solution involves a solenoid valve and its digester. The solenoid valve sets the magnetic core 101 and the valve core 201, and the magnetic core 101 does not directly contact the valve core 201 to drive the valve core 201 to move to realize the interior of the solenoid valve. Action, when the solenoid valve is used on the digester to realize the effect of opening and closing the drain port 501 on the inner pot 5 of the digester, the movement of the valve core 201 can realize the effect of opening and closing the drain port 501, and the power module 8 is used For supplying power to the solenoid valve, the coil 3 inside the solenoid valve can make the valve core 201 and the magnetic core 101 generate a certain magnetic force, and the magnetic core 101 can drive the valve core 201 to move through the magnetic force, mainly the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com