Vehicle weighing state detection system and method

A state detection and detection method technology, applied in the direction of weighing equipment testing/calibration, weighing, measuring devices, etc., can solve the problems of unable to locate faulty sensors, weight loss of weighing system, and unable to detect analog signal values of weighing sensors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

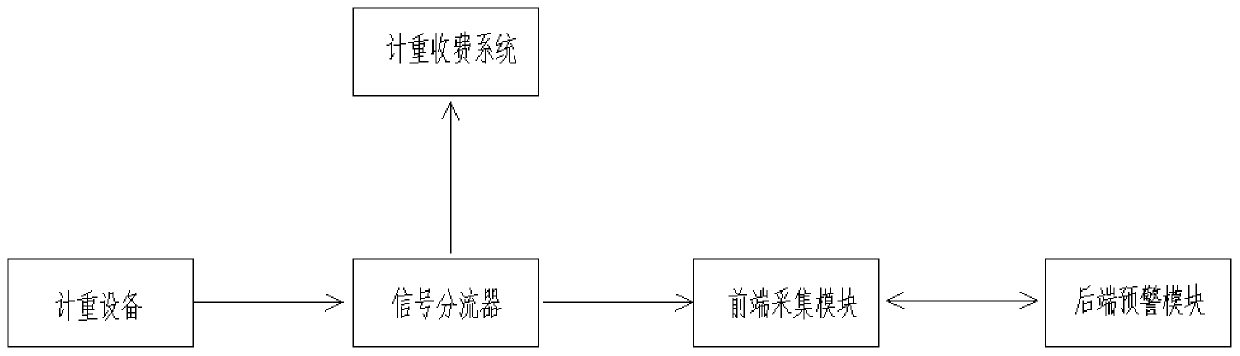

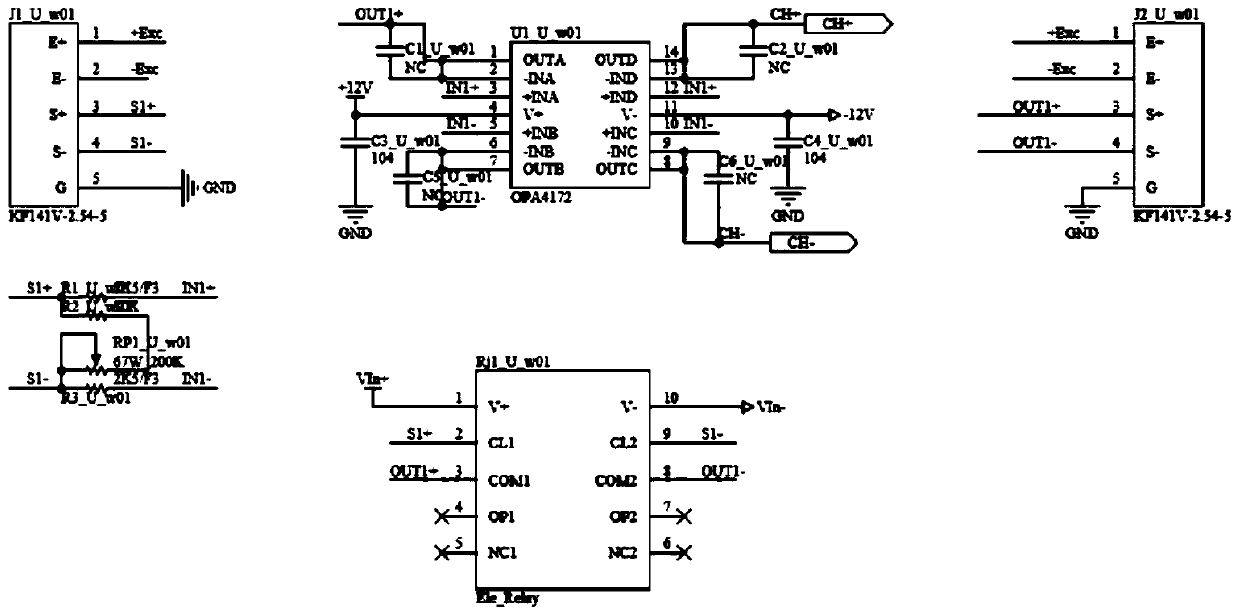

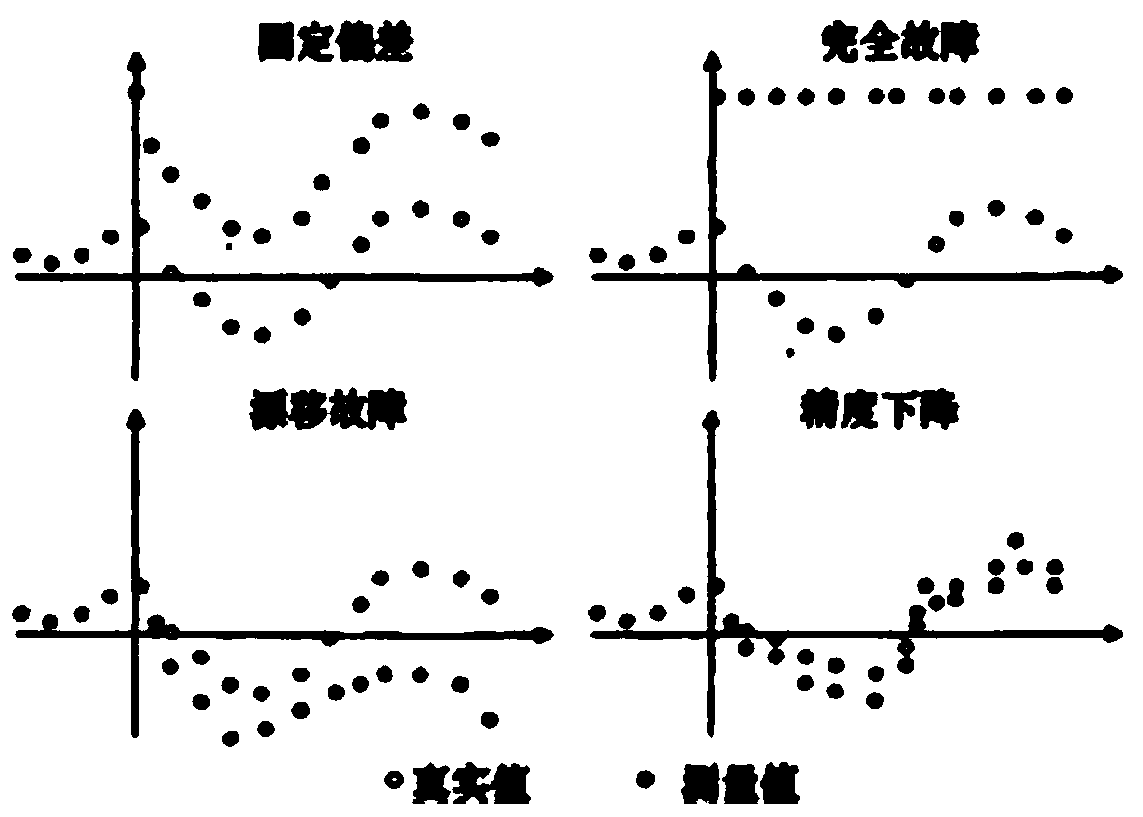

[0032] Such as Figure 1 to Figure 5 As shown, a truck scale weighing state detection system, the detection system includes weighing equipment, weight charging system, signal shunt, front-end acquisition module and back-end early warning module; the signal shunt from the weighing The analog signal is collected on the device, and these analog signals are mirrored by the emitter follower in the signal splitter into two signals with the same size as the original signal, and one of the signals is returned to the weight charging system to ensure the normal operation of the weight charging system Running, the other signal is sent to the front-end acquisition module for data analysis; the front-end acquisition module calculates the weighing result after data analysis of each signal, and returns the calculation result to the back-end early warning module; the back-end early warning module is built with complex The damage of a weighing equipment is a mathematical model based on the wro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com