Axial load and rotary load loaded loading device

A loading device and axial loading technology, which is applied in the direction of measuring devices, elastic testing, mechanical bearing testing, etc., can solve problems such as the inability to realize stepless loading, and achieve large rotational loads, large axial loads, and high precision high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

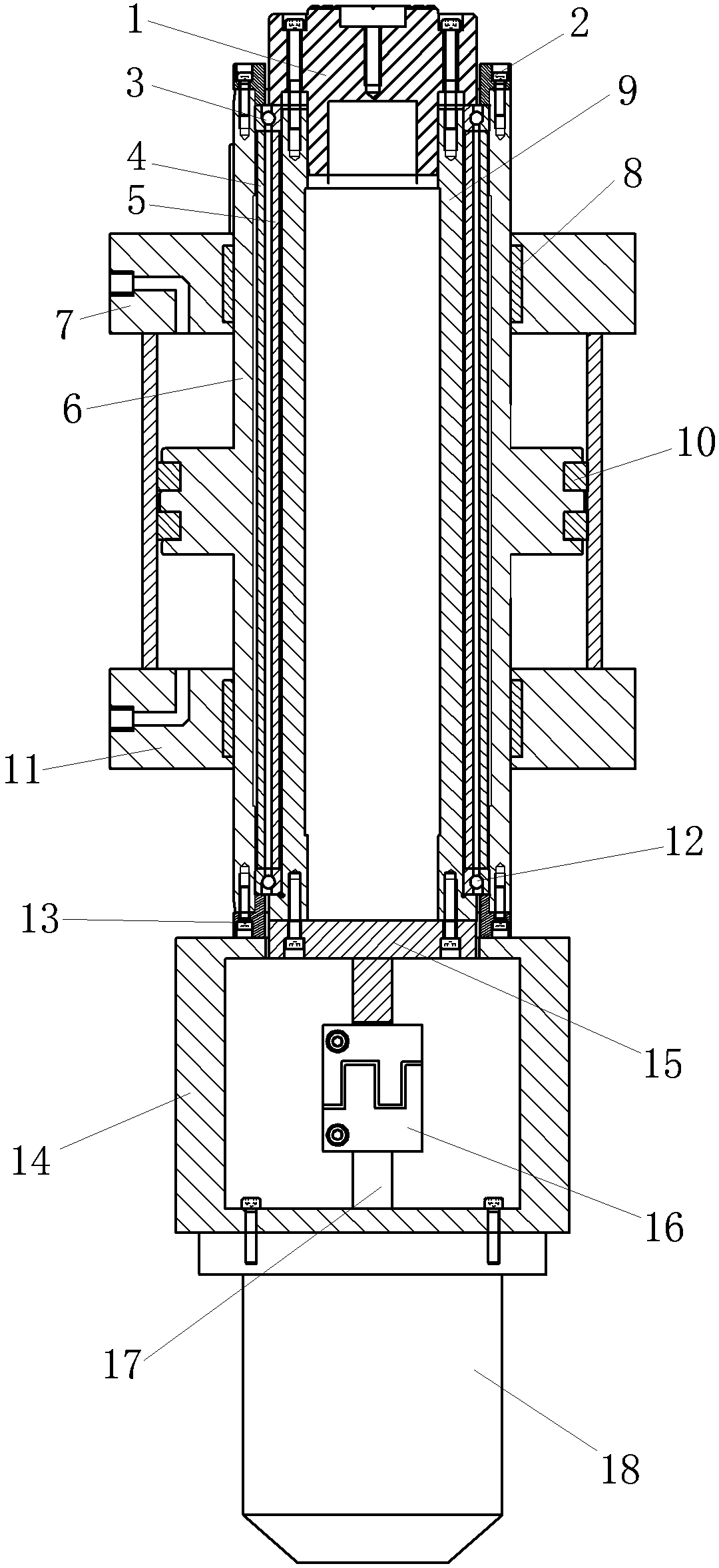

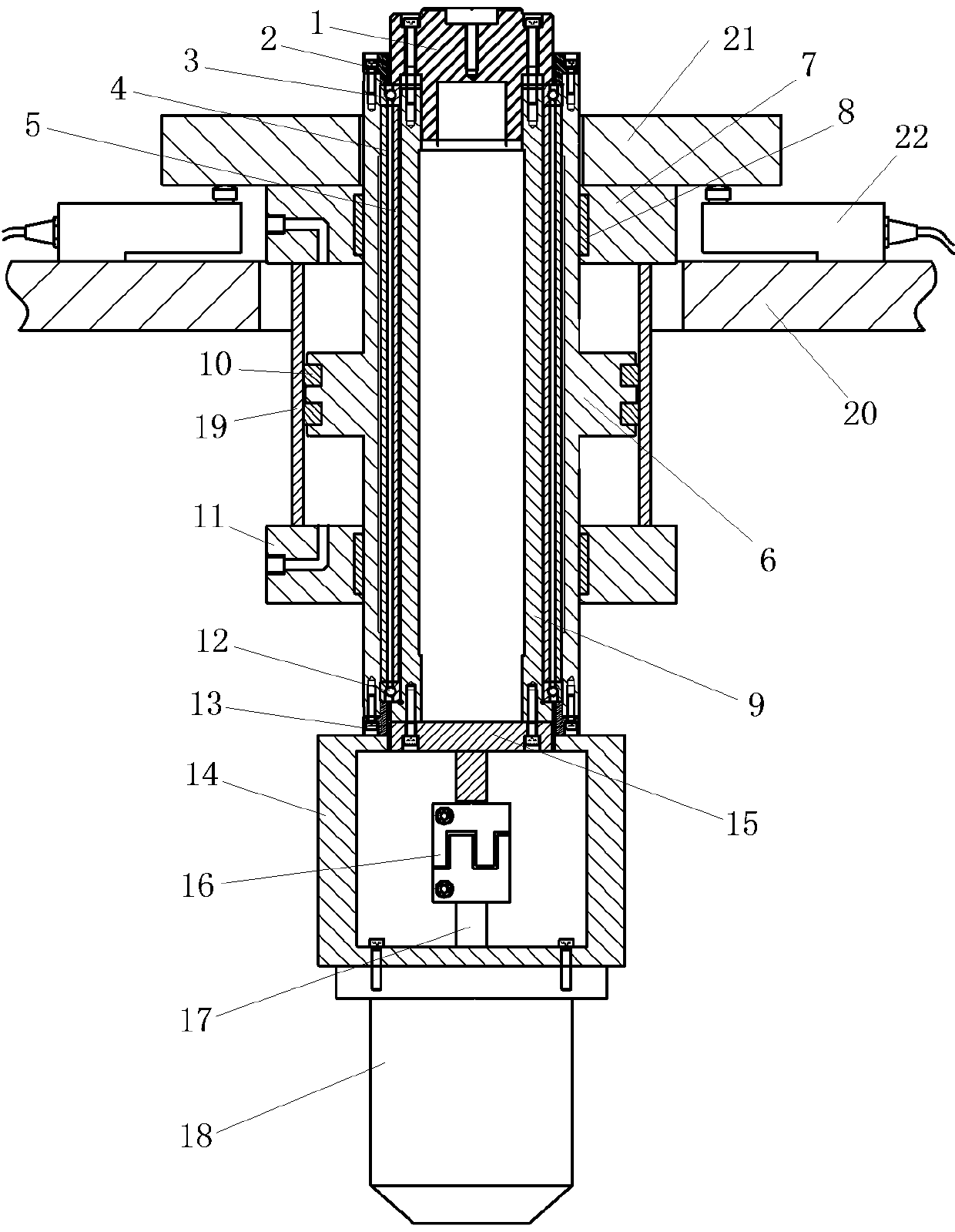

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] A specific embodiment of the loading device integrating axial load loading and rotational load loading of the present invention, such as figure 1 As shown, the loading device integrating axial load loading and rotational load loading includes a cylinder, the cylinder includes a hollow cylinder body and a hollow cylinder plunger 6 slidingly fitted with the cylinder body, and the two ends of the hollow cylinder plunger 6 protrude from the cylinder body respectively. In addition, a hollow rotating shaft 9 is installed in the inner cavity of the plunger, and a pair of angular contact ball bearings are arranged between the hollow air cylinder plunger 6 and the hollow rotating shaft 9, which are respectively the upper bearing 3 and the lower bearing 12, and between the two angular contact ball bearings There is an inner spacer 5 and an outer spacer 4 be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com