A Prediction Method of Fatigue Strength of Metal Materials

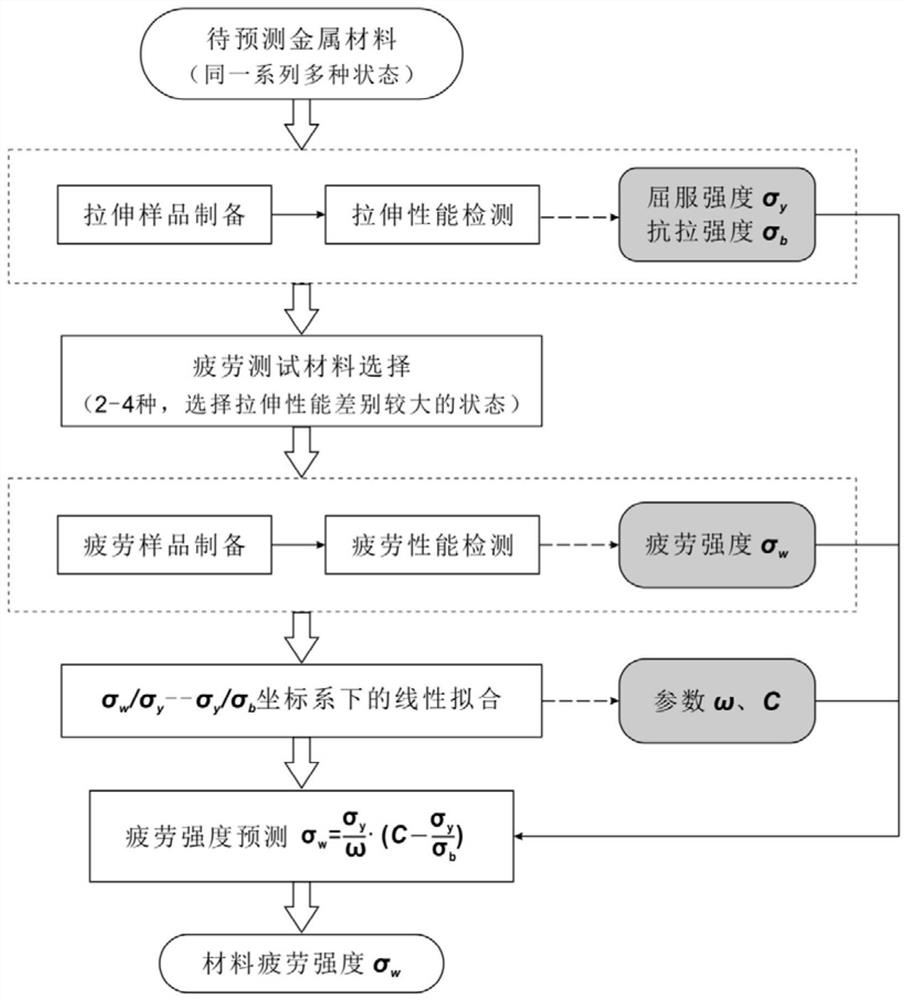

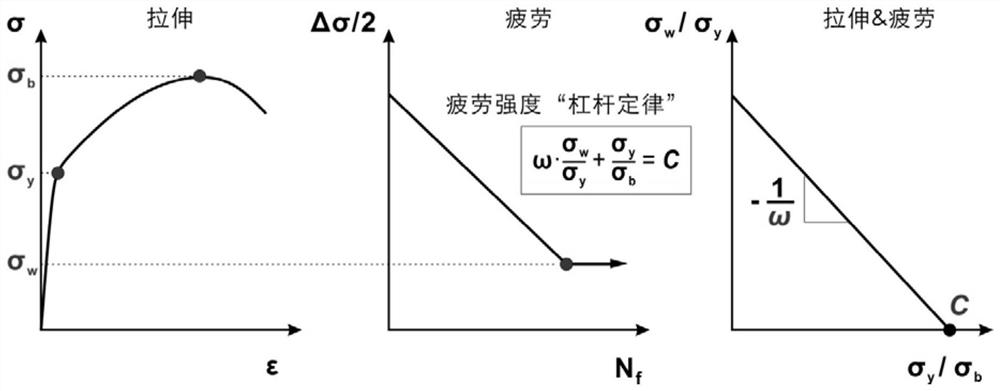

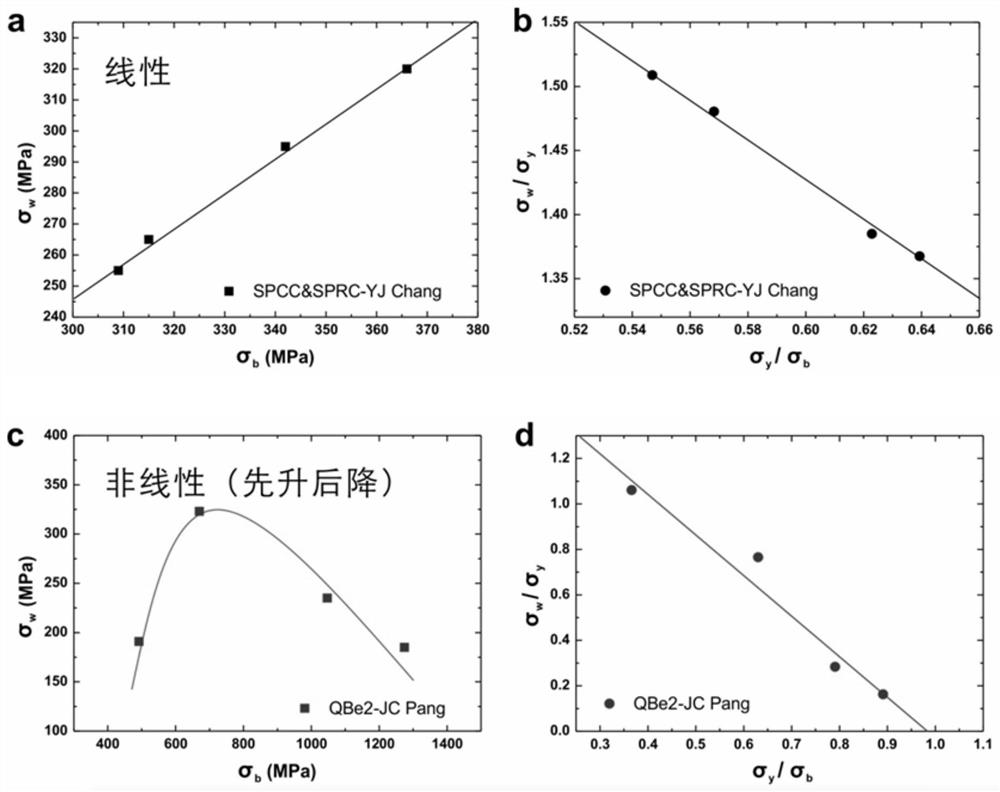

A fatigue strength, metal material technology, applied in the direction of applying stable tension/pressure to test material strength, etc., can solve the problems of high economic cost and time cost of fatigue testing, limited contribution, slow growth trend, etc., and achieve efficient prediction. , Development and selection are convenient, the effect of reducing the amount of fatigue testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment is the prediction of fatigue strength of aluminum alloy, and the specific process is as follows:

[0051] (1) Material:

[0052] 5052 aluminum alloy, different pre-deformation and heat treatment states (O, H32, H34, H36, H38).

[0053] (2) Process:

[0054] Step 1: Tensile performance test. The tensile samples of the above materials are uniformly processed, and the tensile performance test is carried out under the same experimental conditions to obtain the yield strength σ y and tensile strength σ b value (see Table 1 for specific data).

[0055] Step 2: Fatigue test sample selection. In order to minimize the amount of fatigue testing while ensuring the accuracy of the prediction results as much as possible, 2-4 materials with large differences in tensile properties should be selected for fatigue performance testing. Since there are few material states included in this example, only two materials are selected to test the fatigue strength, namely: 5...

Embodiment 2

[0063] This embodiment is the prediction of the fatigue strength of TWIP steel, and the specific process is as follows:

[0064] (1) Material:

[0065] Fe-30Mn-0.9C TWIP steel, different pre-stretching deformation states (original state, pre-stretching 30%, 60%, 70%).

[0066] (2) Process:

[0067] Step 1: Tensile performance test. The tensile samples of the above materials are uniformly processed, and the tensile performance test is carried out under the same experimental conditions to obtain the yield strength σ y and tensile strength σ b value (see Table 2 for specific data).

[0068] Step 2: Fatigue test sample selection. In order to minimize the amount of fatigue testing while ensuring the accuracy of the prediction results as much as possible, 2-4 materials with large differences in tensile properties should be selected for fatigue performance testing. Since there are few material states included in this example, only two materials are selected to test the fatigue ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap