Gas shielded welding machine

A gas shielding and welding machine technology, used in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of no product advantages, unsightly appearance, low efficiency, etc., to improve reliability and safety, and the overall structure is small Beautiful and rational use of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

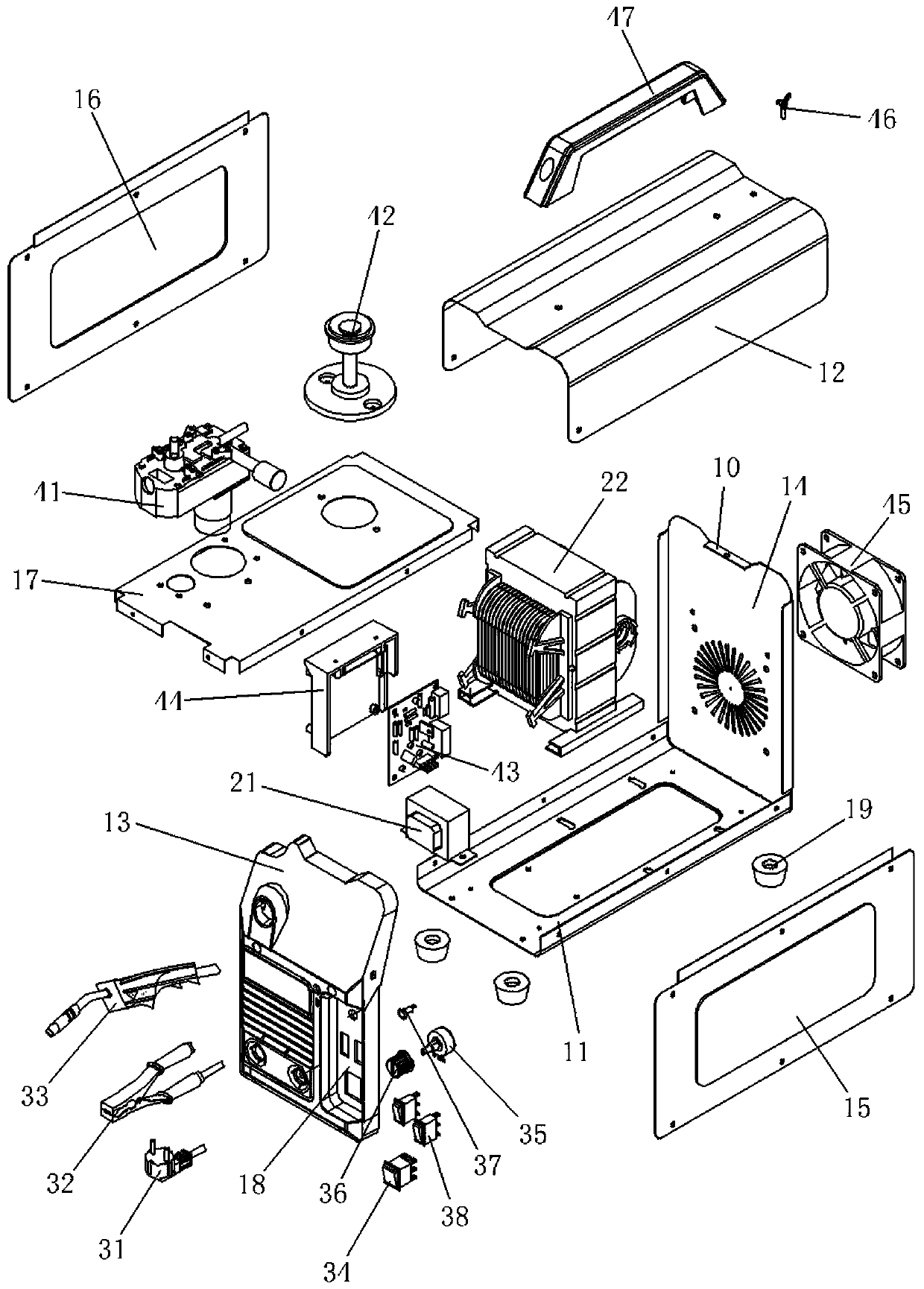

[0019] like figure 1 The gas shielded welding machine shown includes a bottom plate 11, an upper cover plate 12, a front panel 13, a rear panel 14, a left side panel 15 and a right side panel 16, and the front panel 13 is set opposite to the rear panel 14, and the front panel 13 is made of plastic It is made of materials, and the panel and the panel are set opposite to each other. like figure 1 As shown, there are four rubber feet 19 evenly distributed at the four corners of the bottom plate 11 under the bottom plate 11 .

[0020] like figure 1 As shown, a power transformer 21 and a main transformer 22 are provided on the base plate 11, and a power plug 31, a grounding clip 32, a welding torch 33, a power switch 34 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com