Open socket spanner for narrow and small space

A socket wrench and narrow space technology, which is applied in the direction of wrenches, screwdrivers, manufacturing tools, etc., can solve the problems of inability to pass through pipelines, inconvenient operation, and limited movement of open-end wrenches, so as to achieve convenient and efficient operation and increase the scope of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

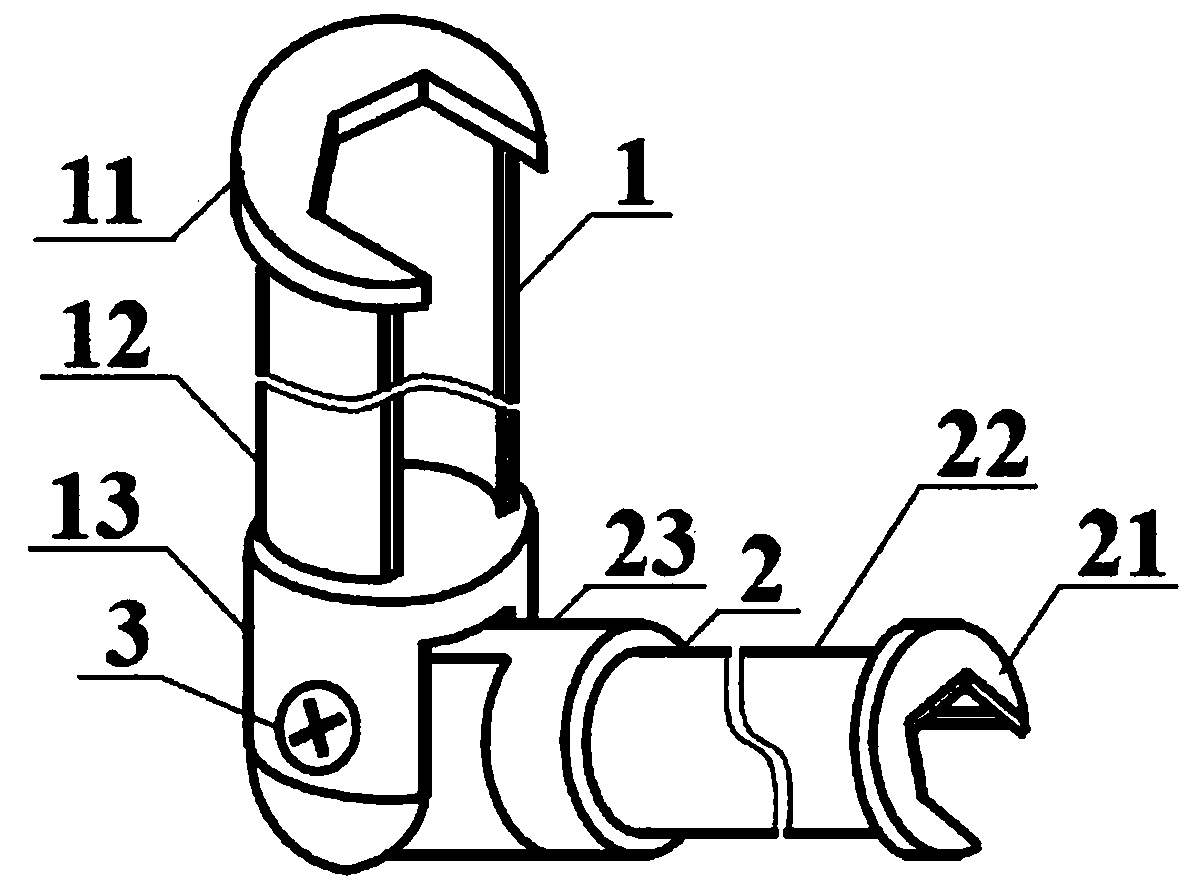

[0015] figure 1 It is a schematic diagram of the overall structure of the present invention. The present invention comprises main wrench 1, auxiliary wrench 2 and connecting shaft 3, as figure 1 As indicated, high carbon steel or alloy steel materials are preferred for quenching treatment. The main wrench 1 includes a main wrench head 11 , a main sleeve 12 and a main wrench handle 13 , which are connected and clamped with bolts or nuts to be disassembled for assembly and disassembly operations. The main wrench head 11 is preferably formed by stamping high carbon steel or alloy steel plate, and then ground and polished. The main sleeve 12 is a cylindrical structure, preferably high carbon steel or alloy steel plate is bent and formed, and then ground and polished. The rigid connection between one end of the main s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com