A method for preparing high-purity red lead by reclaiming waste lead plaster by wet method with filtrate circulation

A technology for waste lead paste and filtrate, applied in the field of preparing high-purity red dan, can solve the problems of high content of impurity elements, large dosage of leaching reagents, etc., and achieve the effects of high-efficiency leaching, enhanced complexing ability, and improved economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

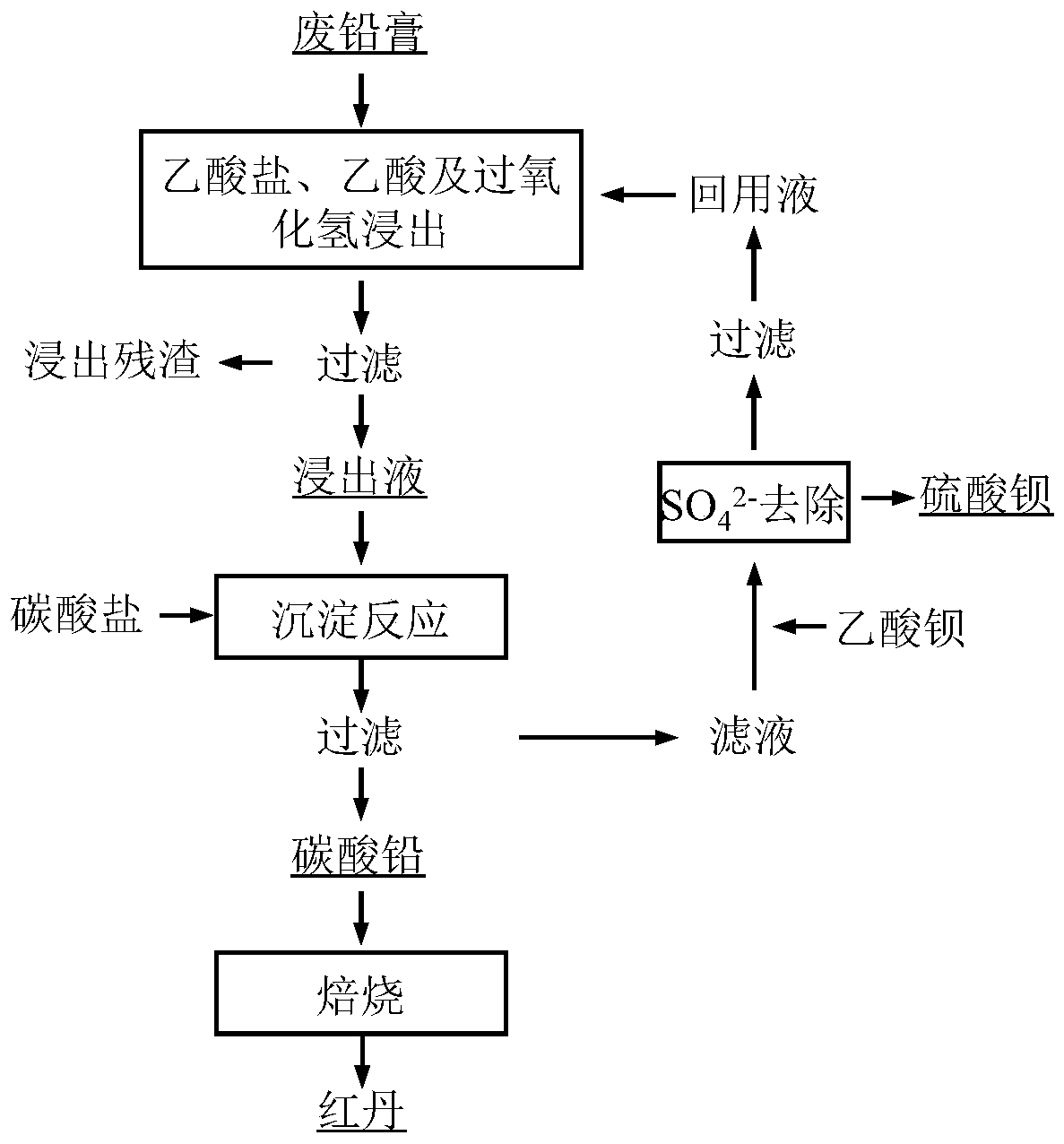

[0057] figure 1 A process flow chart for the preparation of high-purity red lead based on wet recovery of waste lead paste based on filtrate circulation provided by the present invention. Waste lead paste (SLP) raw material is 9g, the dosage of ammonium acetate in the wet leaching process is 64mmol / g SLP, the dosage of acetic acid is 3mmol / g SLP, the dosage of hydrogen peroxide is 3mmol / gSLP, and the solid-liquid ratio is controlled at 90g / L, the pH was adjusted to 7.6. After leaching for 2 hours, separate by filtration to obtain leachate and residue. The concentration of lead ions in the leaching solution is 0.30mol / L, the concentration of the ammonium carbonate reagent added is 2mol / L, the volume of the ammonium carbonate added is 15mL, the pH is adjusted to 8.6 with ammonia water, the cation of the reagent for adjusting the pH is the same as that in the organic acid The cations are kept consistent to avoid introducing other impurity elements. In this embodiment, the cati...

Embodiment 2

[0059] The waste lead paste raw material is 9g, the dosage of ammonium acetate in the wet leaching process is 70mmol / g SLP, the dosage of acetic acid is 6mmol / g SLP, the dosage of hydrogen peroxide is 2mmol / g SLP, and the solid-liquid ratio is controlled at 100g / L , the pH was adjusted to 7.0. After leaching for 1 hour, filter and separate to obtain leachate and residue. The lead ion concentration in the leaching solution is 0.35mol / L, the concentration of the ammonium carbonate reagent added is 4mol / L, the volume of the ammonium carbonate added is 8mL, the pH is adjusted to 8.0 with ammonia water, and the reaction is 0.5h, and the solid-liquid mixture after the reaction is Seal it and place it in an environment of 80°C for aging for 6 hours to improve the filtration performance of lead carbonate. Subsequently, the lead carbonate product and filtrate were obtained by filtration. The sulfate ion concentration in the filtrate is 0.16mol / L, and 4.55g barium acetate is added in ...

Embodiment 3

[0061] The raw material of waste lead paste is 9g. During the wet leaching process, the dosage of ammonium acetate is 50mmol / g SLP, the dosage of acetic acid is 1mmol / g SLP, the dosage of hydrogen peroxide is 8mmol / g SLP, and the solid-liquid ratio is controlled at 60g / L , the pH was adjusted to 8.0. After leaching for 6 hours, filter and separate to obtain leachate and residue. The concentration of lead ions in the leach solution is 0.20mol / L, the concentration of ammonium carbonate reagent added is 2mol / L, the volume of ammonium carbonate added is 14mL, the pH is adjusted to 8.5 with ammonia water, the reaction is 2h, and the solid-liquid mixture after the reaction is sealed. , aged at 40°C for 24 hours to improve the filtration performance of lead carbonate. Subsequently, the lead carbonate product and filtrate were obtained by filtration. The sulfate ion concentration in the filtrate is 0.16mol / L, and 4.55g barium acetate is added in the filtrate. After standing still f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com