Photographing robot mechanism capable of freely moving in plane

A technology of a robot and a driving mechanism, applied in the field of photographic robots, can solve problems such as inconvenience, and achieve the effect of improving working space, improving flexibility, and eliminating laying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The invention proposes a novel camera robot mechanism that can move freely in a plane, and is mainly used to adjust the spatial position of the camera and the terminal attitude adjustment system.

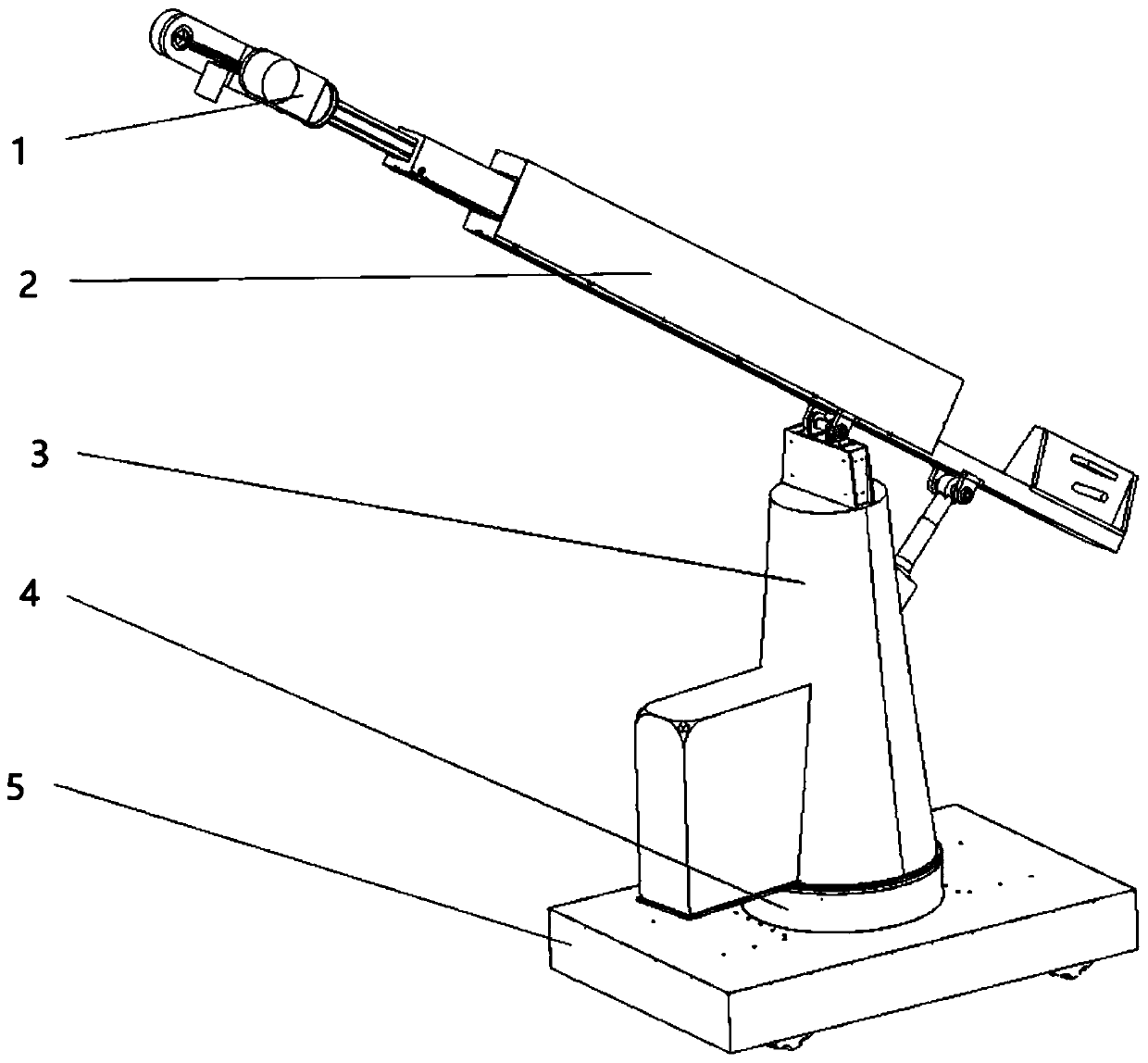

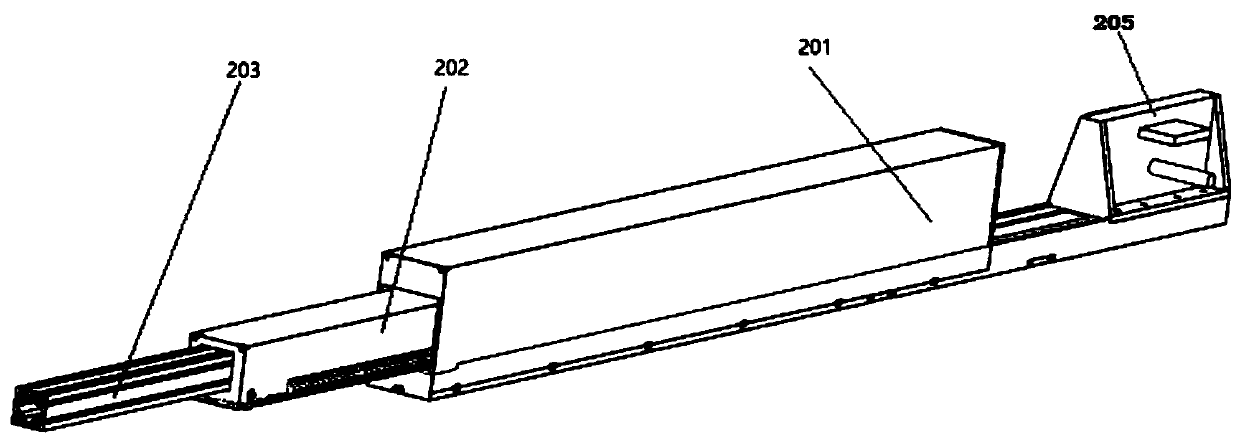

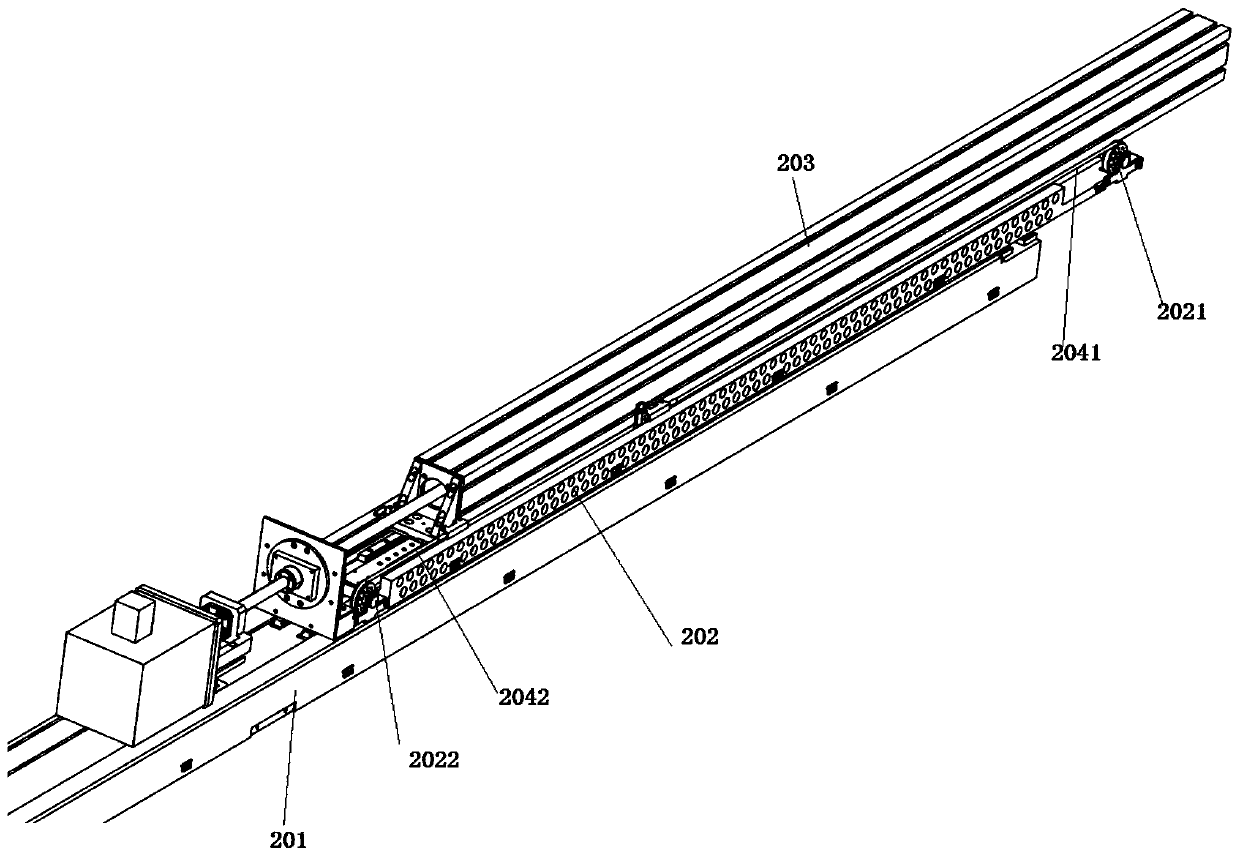

[0032] Such as figure 1 As shown, the camera robot mechanism that can move freely in a plane includes a top-level telescopic mechanism 2, a pitch mechanism 3, a rotating platform 4, and an AGV motion platform 5 that are sequentially connected from top to bottom. Also be connected with attitude control pan-tilt 1 on the telescoping mechanism 2 on the top layer.

[0033] The present invention uses the AGV motion platform 5 to replace the track axis in the prior art, so that the camera robot can move freely on the plane, improve the flexibility of on-site shooting, and eliminate the track laying time. Since the upper structure of the photography robot needs to be adjusted according to the photography requirements, in order to maintain the stable operation of the photography rob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com