Shedding detecting method and system of refrigerating system exhaust temperature sensor

An exhaust temperature and refrigeration system technology, applied in refrigeration safety arrangements, refrigerators, refrigeration components, etc., can solve the problem of low detection accuracy of exhaust temperature sensor shedding, avoid the risk of shedding or failure, and achieve accurate shedding detection. , to ensure the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

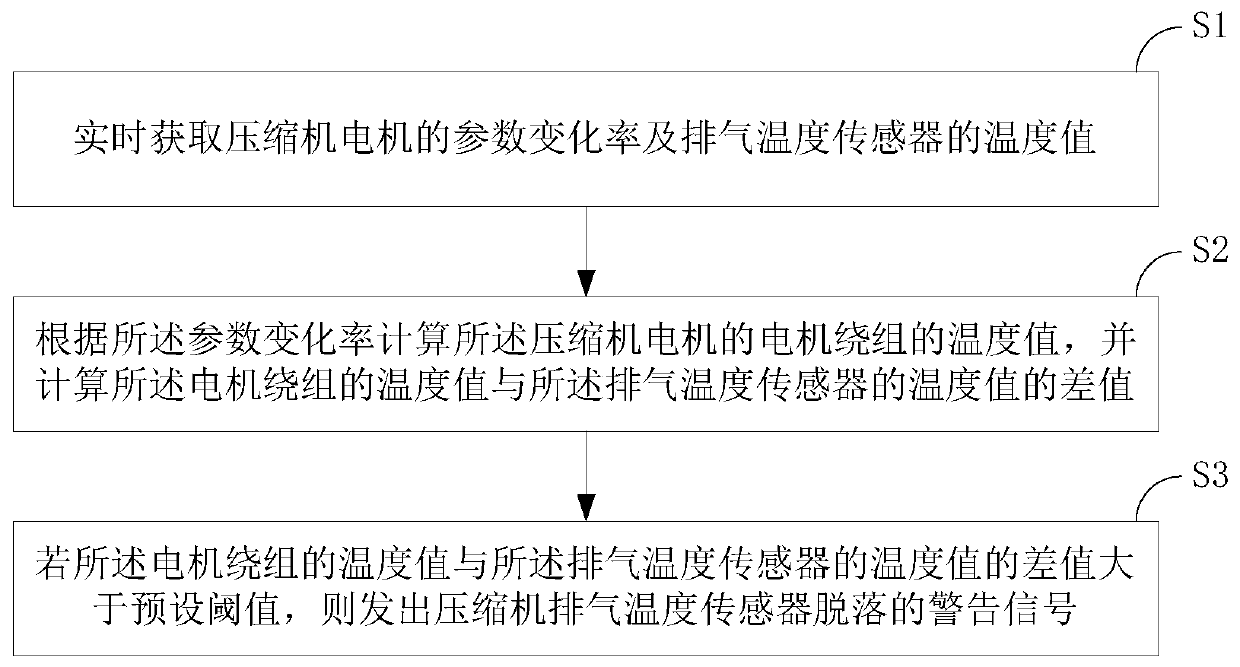

[0036] The embodiment of the present invention aims to provide a detection method for the drop-off of the exhaust temperature sensor of the refrigeration system, which is used to solve the problem that the detection accuracy of the discharge temperature sensor of the existing refrigeration system is not high, such as figure 1 As shown, the process of this method can be described as follows:

[0037] S1. Obtain the parameter change rate of the compressor motor and the temperature value of the exhaust temperature sensor in real time.

[0038] In the embodiment of the present invention, the refrigeration system may be a DC frequency conversion refrigeration system, such as a DC frequency conversion air conditioning system, a DC frequency conversion refrigerator system or other refrigeration systems. The compressor in the refrigeration system is driven by a motor to work, wherein the motor may be a A power source device that generates a rotating magnetic field and acts on the roto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com