Cerenkov terahertz radiation source based on cylinder graphene surface plasma wave

A surface plasmon and terahertz radiation source technology, applied in the field of radiation source engineering, can solve problems such as fragility, low energy conversion efficiency, and difficult realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] specific implementation plan

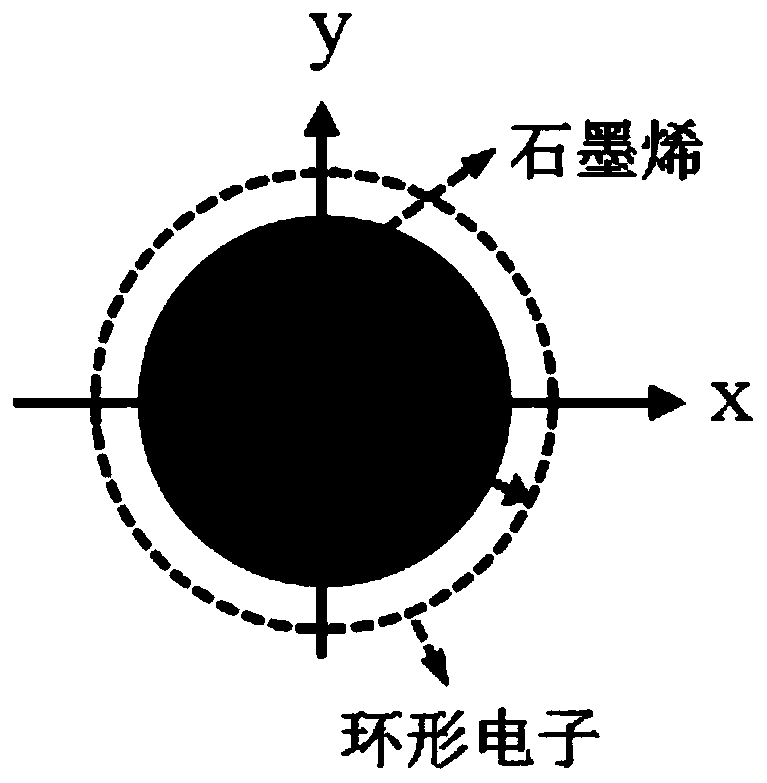

[0035] An example is a graphene fully wrapped cylindrical dielectric rod. figure 1A schematic diagram of the structure is given. From the inside to the outside are the internal dielectric rods, graphene and ring electronics. The fabrication and processing of this structure also follows the principle from the inside to the outside. First, stick the graphene ribbon grown by copper-based chemical vapor deposition with adhesive tape, cover it on the cylindrical dielectric rod, then dissolve the tape with a solution, and finally use nanosecond fiber laser from both sides of the cylindrical dielectric rod The graphene is cut so that a cylindrical graphene structure completely enveloping the dielectric rod is produced.

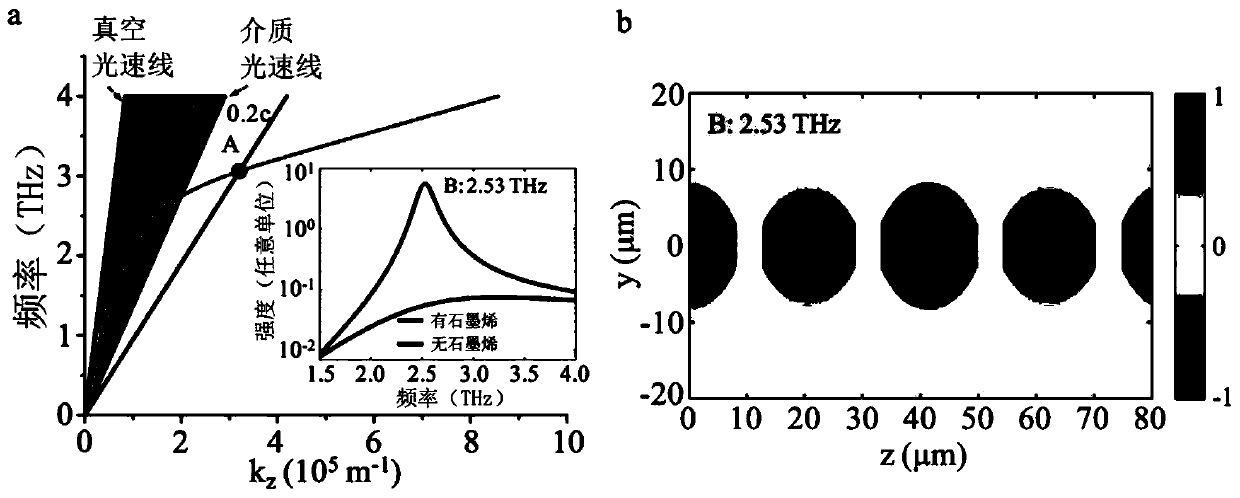

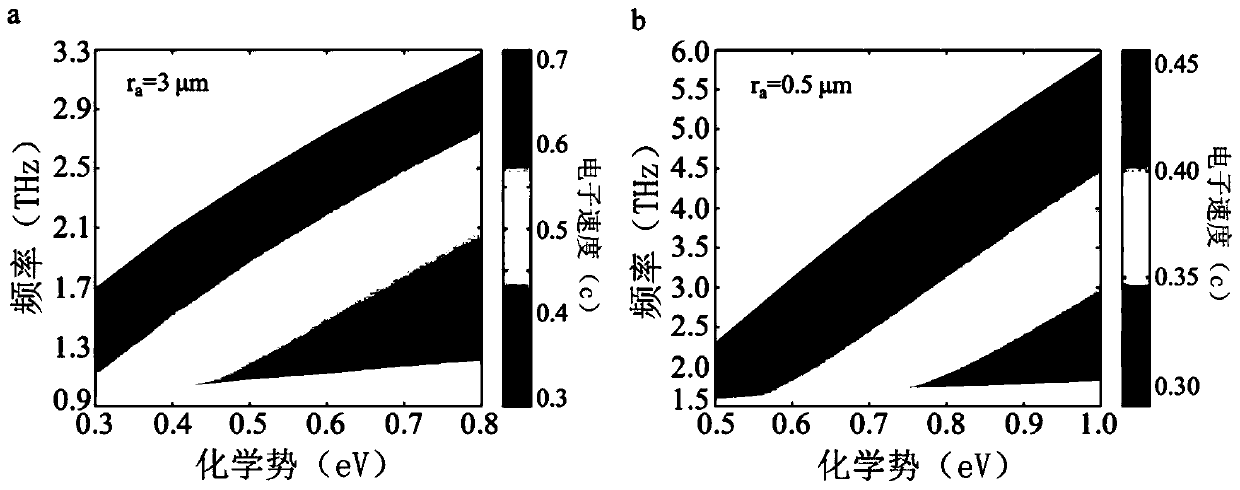

[0036] The graphene SPPs will be excited by ring electrons emitted from the ring cathode and skimming off the outer surface of the structure. Due to the 2π periodicity of the cylindrical graphene dielectric rod structure in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com