Automatic dewatering device for mine compressed air system

An air system and automatic technology, which is applied in the direction of steam condensation, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of reducing the service life of equipment, affecting the normal use of compressed air system, corrosion of valves and pipelines, and improving condensation effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0027] Example 1

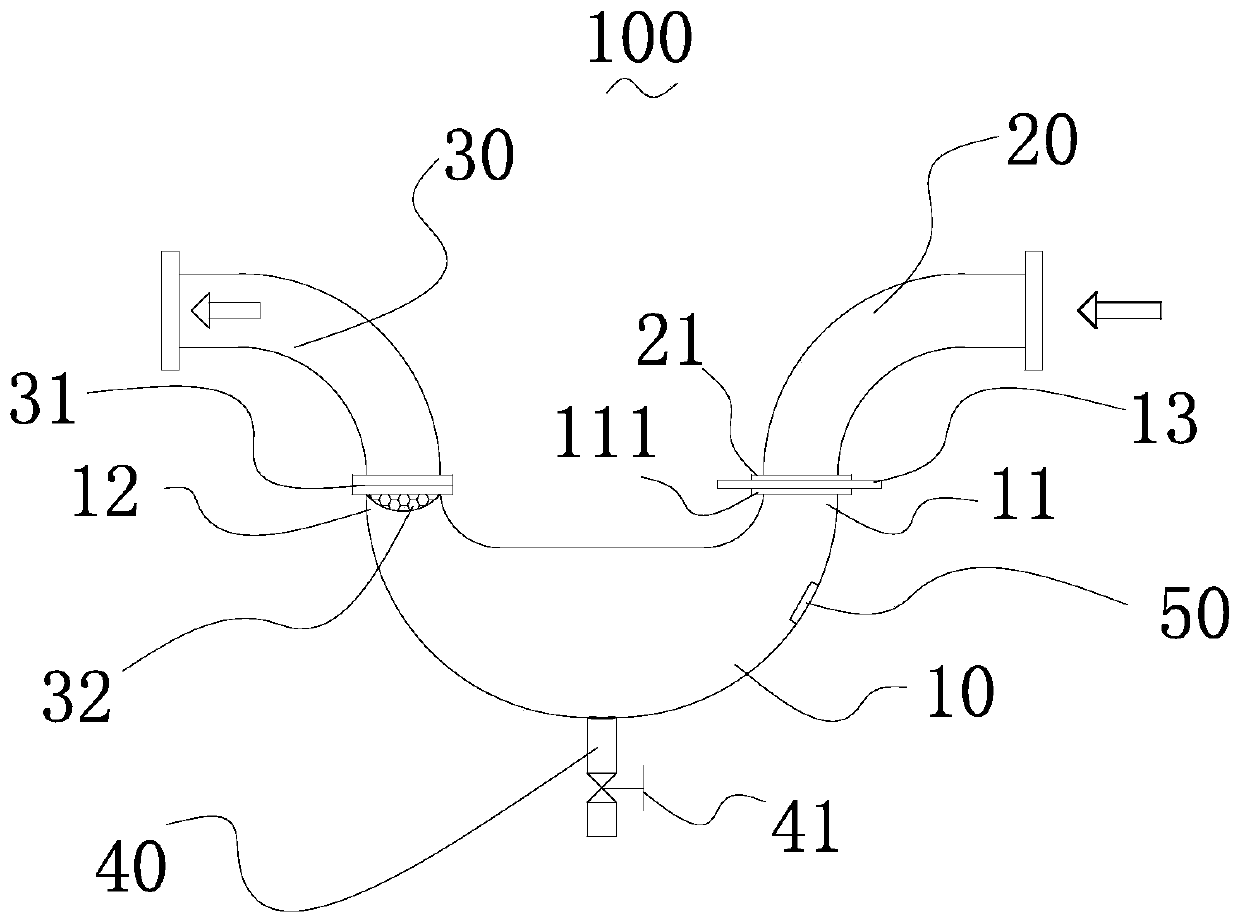

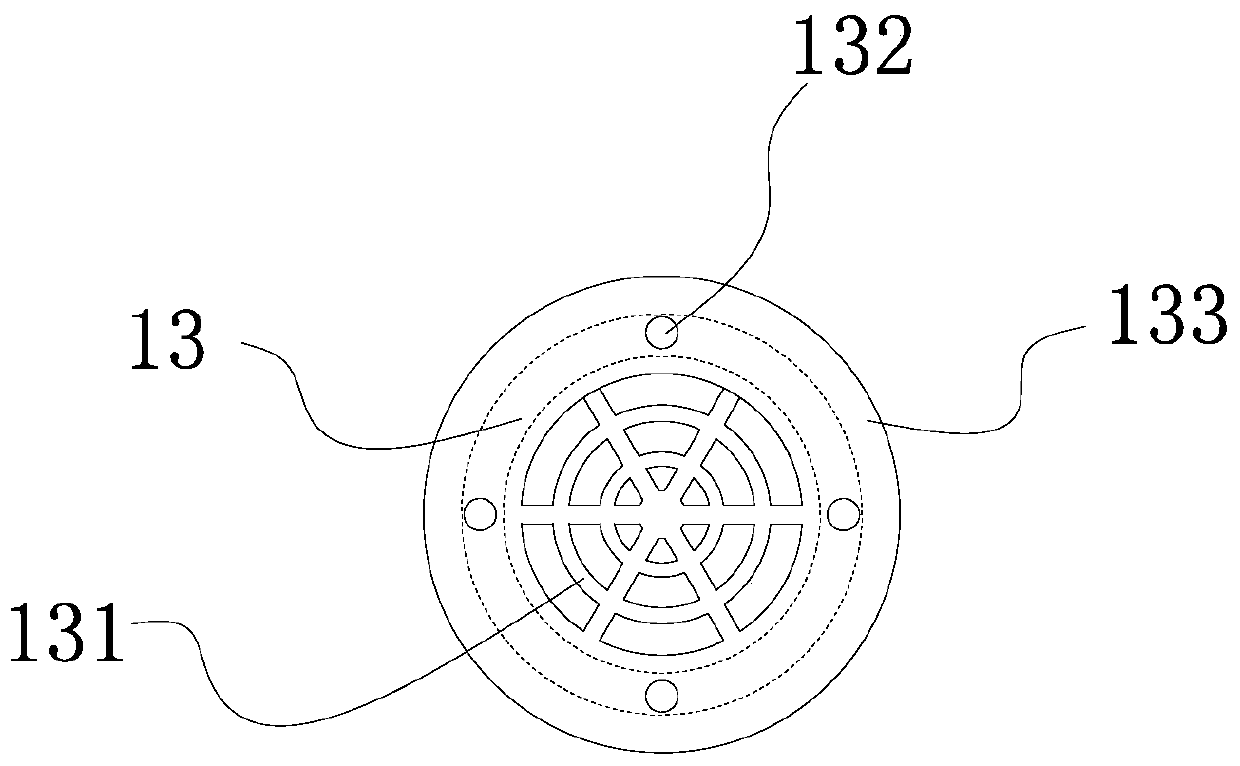

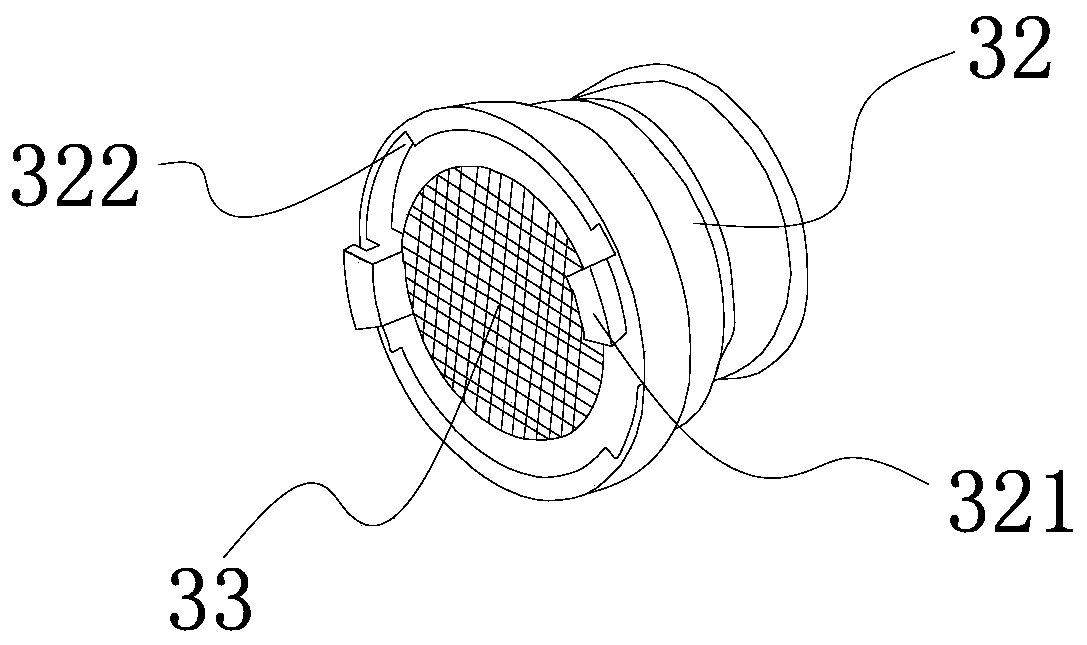

[0028] Please refer to Figure 1-3 As shown, an automatic water removal device 100 for a mine air pressure system includes a water removal cavity 10, an air inlet pipe 20, an air outlet pipe 30, and a drain pipe 40. The air inlet 11 above the water removal cavity 10 and the The air inlet pipe 20 is in communication, the air outlet 12 above the dewatering chamber 10 is in communication with the air outlet pipe 30, and the drain pipe 40 is provided below the dewatering chamber 10, and the inlet of the dewatering chamber 10 A condensing pan 13 is sealed between the tuyere 11 and the air inlet pipe 20. The condensing pan 13 has a mesh 131 in the middle, and the outer edge 133 of the condenser pan 13 extends to the outside of the air inlet 11.

[0029] In this embodiment, the dewatering cavity 10 is a closed hollow structure, the cavity at the bottom of the dewatering cavity 10 is oblate, and the interior and exterior of the dewatering cavity 10 are provided with ant...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap