Underglaze kiln-changing glaze pigment and method for preparing underglaze kiln-changing glaze ceramic products using it

A technology for ceramic products and kiln-changing glazes, which is applied in the field of underglaze kiln-changing glaze pigments and the preparation of underglaze kiln-changing glaze ceramic products. Reduce pinhole phenomenon, enhance appreciation, improve the effect of glaze transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

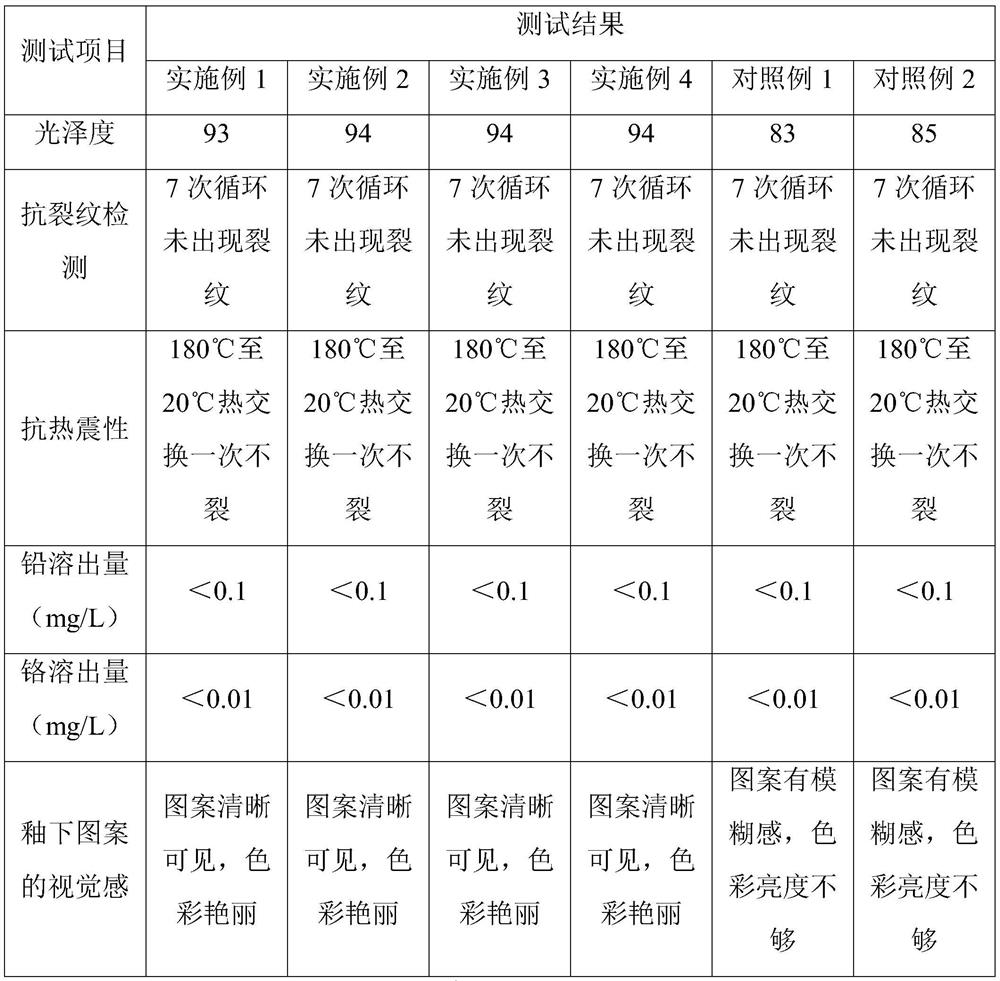

Examples

Embodiment 1

[0039] The underglaze kiln-changing glaze pigment includes the following components in parts by mass: 8 parts of kaolin, 32 parts of feldspar, 25 parts of quartz, 8-10 parts of rutile, 6-8 parts of lanthanum oxide, and 1-8 parts of glyceryl trioleate 2 parts, 1 part of dioctyl phthalate, 3 parts of lapis lazuli, 3 parts of fluorite, 3 parts of manganite, 6 parts of purple wood knot, 3 parts of pigment.

[0040] The method for preparing an underglaze kiln-changing glaze ceramic product by using the underglaze kiln-changing glaze pigment comprises the following steps:

[0041] Step 1, mixing materials:

[0042] After the kaolin, feldspar, quartz, rutile, lanthanum oxide, lapis lazuli, fluorite, manganese iron ore and purple wood knot are broken separately according to the mass parts, the crushed materials of each component are obtained, and then each The crushed material of the components is mixed and stirred evenly to obtain the mixed material;

[0043] Step two, ball milling...

Embodiment 2

[0064] The underglaze kiln-changing glaze pigment includes the following components in parts by mass: 9 parts of kaolin, 34 parts of feldspar, 28 parts of quartz, 9 parts of rutile, 7 parts of lanthanum oxide, 2 parts of triolein, phthalate 2 parts of dioctyl formate, 4 parts of lapis lazuli, 4 parts of fluorite, 4 parts of manganite, 7 parts of purple wood knot, 4 parts of pigment.

[0065] The method for preparing an underglaze kiln-changing glaze ceramic product by using the underglaze kiln-changing glaze pigment comprises the following steps:

[0066] Step 1, mixing materials:

[0067] After the kaolin, feldspar, quartz, rutile, lanthanum oxide, lapis lazuli, fluorite, manganese iron ore and purple wood knot are broken separately according to the mass parts, the crushed materials of each component are obtained, and then each The crushed material of the components is mixed and stirred evenly to obtain the mixed material;

[0068] Step two, ball milling:

[0069] Carry ou...

Embodiment 3

[0089] The underglaze kiln-changing glaze pigment includes the following components in parts by mass: 10 parts of kaolin, 38 parts of feldspar, 30 parts of quartz, 8 parts of rutile, 6 parts of lanthanum oxide, 2 parts of triolein, phthalate 1 part of dioctyl formate, 3 parts of lapis lazuli, 4 parts of fluorite, 4 parts of manganite, 8 parts of purple wood knot, and 5 parts of pigment.

[0090] The method for preparing an underglaze kiln-changing glaze ceramic product by using the underglaze kiln-changing glaze pigment comprises the following steps:

[0091] Step 1, mixing materials:

[0092] After the kaolin, feldspar, quartz, rutile, lanthanum oxide, lapis lazuli, fluorite, manganese iron ore and purple wood knot are broken separately according to the mass parts, the crushed materials of each component are obtained, and then each The crushed material of the components is mixed and stirred evenly to obtain the mixed material;

[0093] Step two, ball milling:

[0094] Carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com