Flame Retardant Pressure Sensitive Adhesive and Its Application

A technology of pressure-sensitive adhesives and inorganic flame retardants, applied in the direction of pressure-sensitive films/sheets, adhesives, non-polymer adhesive additives, etc., can solve the problems such as the complicated preparation process of carboxyl phosphorus-containing copolyesters, and achieve adhesion Good performance, the effect of improving flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] The preparation of embodiment 1 urushiol-based phosphorus-containing polymer D1

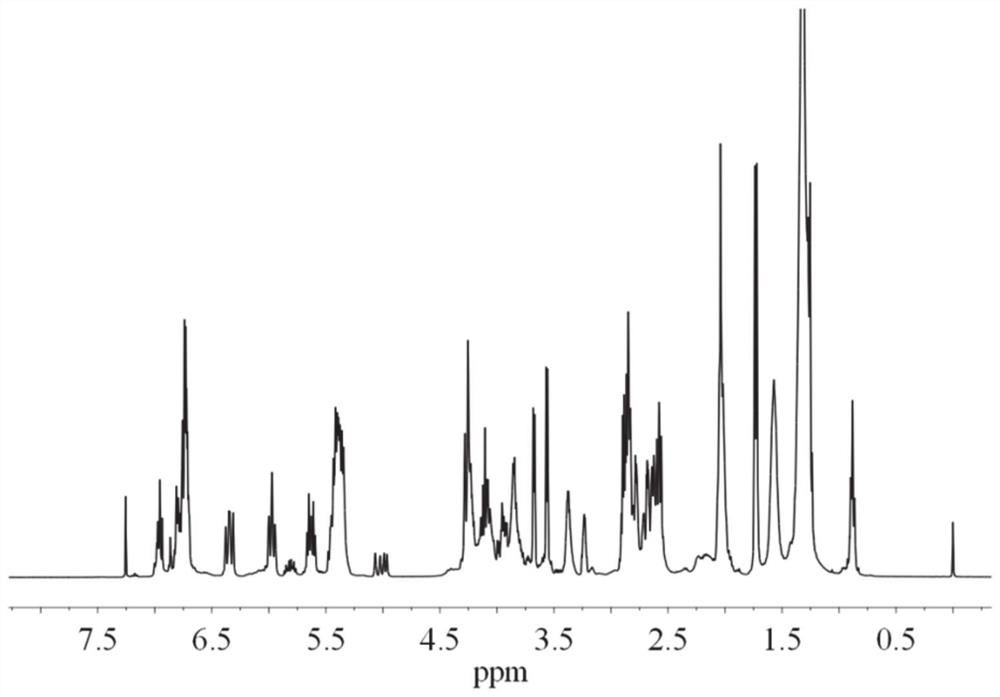

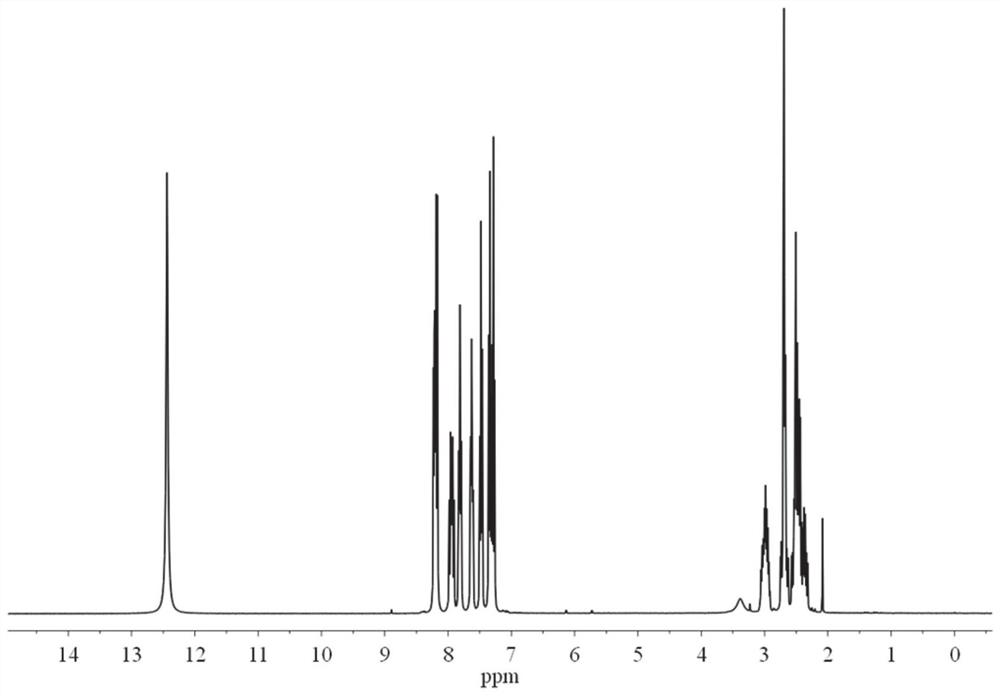

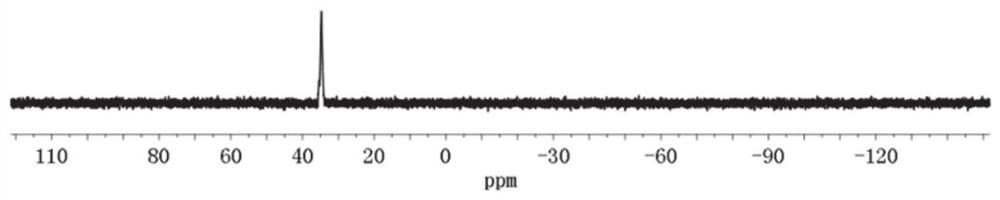

[0076] Synthesis and Characterization of a1 Urushiol-based Diglycidyl Ethers

[0077] Add 0.3 mol of urushiol and 0.6 mol of epichlorohydrin into a four-neck flask equipped with a stirrer, reflux condenser, thermometer, and dropping funnel, heat up to 55°C, and add 60 ml of 10 mol of / L NaOH solution for 1.5 hours. After the dropwise addition, the temperature was raised to 65° C., and the reaction was carried out at a constant temperature for 5 hours to obtain a mixture containing urushiol bis-shrunk oil ether, water, and sodium chloride. Add xylene and water to the mixture containing urushiol diglycidyl ether, water, and sodium chloride, wash with water, let stand overnight and separate layers, remove the inorganic matter in the water layer, wash repeatedly, and distill under reduced pressure to obtain urushiol-based diglycidol Ether compounds, denoted as r1-1 # .

[0078] Urushiol-bas...

Embodiment 2

[0100] The preparation of embodiment 2 urushiol-based phosphorus-containing polymer D2

[0101] Synthesis and Characterization of a2 Urushiol-based Diglycidyl Ethers

[0102] Add 0.3 mol of urushiol and 0.6 mol of epichlorohydrin into a four-necked flask equipped with a stirrer, reflux condenser, thermometer, and dropping funnel, heat up to 55°C, and add 30 ml of 10 mol of / L KOH solution for 2 hours, after the dropwise addition, the temperature was raised to 65°C, and the reaction was carried out at constant temperature for 4 hours to obtain a mixture containing urushiol bis-shrunk oil ether, water, and sodium chloride. Add xylene and water to the mixture containing urushiol diglycidyl ether, water, and sodium chloride, wash with water, let stand overnight and separate layers, remove the inorganic matter in the water layer, wash repeatedly, and distill under reduced pressure to obtain urushiol-based diglycidol Ether compounds, denoted as r2-1 # .

[0103] Urushiol-based di...

Embodiment 3

[0119] Embodiment 3 Preparation of Flame Retardant Pressure Sensitive Adhesive 1#

[0120] The preparation method of the flame-retardant pressure-sensitive adhesive is: mix 60.0g of urushiol-based phosphorus-containing polymer D1, 1.0g of curing agent TDI, and 39.0g of ethyl acetate under mechanical stirring to obtain a flame-retardant pressure-sensitive adhesive. Glue, recorded as sample 1#.

[0121] In sample 1#, the mass content of each component is:

[0122] Urushiol-based phosphorus-containing polymer D1: 60%;

[0123] Curing agent TDI: 1%;

[0124] Ethyl acetate: 39%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com