T-shaped plug-in type reinforced connecting pitch point of fabricated wall board

A technology of strengthening connection and plug-in type, applied in the direction of walls, building components, thermal insulation, etc., can solve the problems of poor thermal insulation performance and earthquake resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

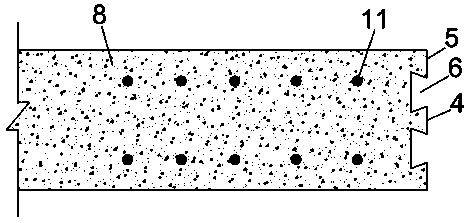

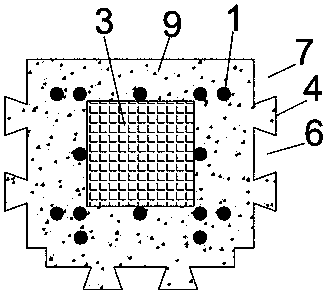

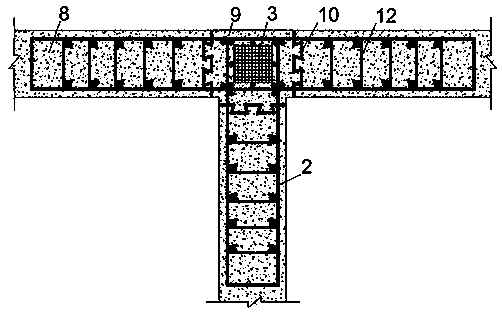

[0018] Example: such as figure 1 - As shown in -4, a T-shaped plug-in reinforced connection node of an assembled wallboard of the present invention includes a stirrup anchoring steel bar 1, a stirrup 2, a connecting wooden keel 3, a convex body clip end-4, and a convex body clip End two 5, groove one 6, groove two 7, dividing wallboard 8, connecting wallboard 9, non-thermal bridge shock-absorbing elastic filling material 10, tie connecting steel bars 11 and tie bars 12, characterized in that:

[0019] In the structure of the sub-wall panel 8, two rows of tie connecting steel bars 11 are arranged at the connection ends of the sub-wall panel 8 and the connecting wall panel 9, and a convex body clip end one 4 and two convex body clip ends two 5 are set. Groove one 6 is set between the convex body clamp end one 4 and the convex body clamp end two 5; in the structure connecting the wallboard 9, a groove one 6, Two grooves two 7, between the groove one 6 and the groove two 7, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com