Heat-free bridge line-shaped reinforced node of fabricated insulation board

A thermal insulation board and assembled technology, which is applied in the direction of thermal insulation, building components, walls, etc., can solve the problems that the thermal insulation effect cannot be kept in good condition for a long time, the living comfort is reduced, and the thermal insulation capacity is weakened, so as to avoid the thermal bridge effect and improve Connection strengthening effect, installation operation simplification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further illustrate the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but they should not be construed as limiting the protection scope of the present invention.

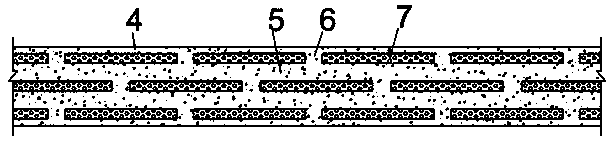

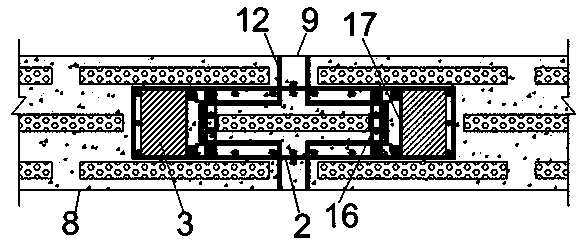

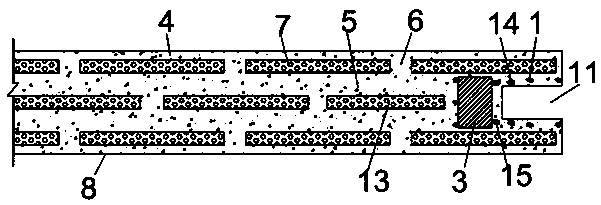

[0022] Example: such as Figure 1-4 As shown, an in-line reinforced node without a heat bridge of an assembled thermal insulation board of the present invention includes a stirrup anchoring steel bar 1, a stirrup 2, a connecting wooden keel 3, a concrete outer layer 4, a concrete intermediate layer 5, and a concrete rib 6 , main insulation board 7, sub-wall board 8, connecting wall board 9, convex part 10, concave part 11, thermal insulation bonding mortar 12, matching thermal insulation board 13, anchor ring anchoring steel bar 14, tie bar anchoring steel bar 15, anchor ring 16 And tie bars 17, in the structure of the in-line reinforced joint without thermal bridge of the prefabricated insulation board, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com