Fabricated sandwich insulating plate and cross-shaped anti-shock energy-consumption joint thereof

A thermal insulation board and prefabricated technology, applied in thermal insulation, shockproof, protective buildings/shelters, etc., can solve the problems of thermal insulation effect not being able to maintain a good state for a long time, air pollution, and reduced living comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

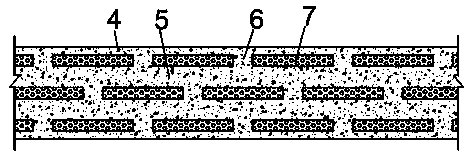

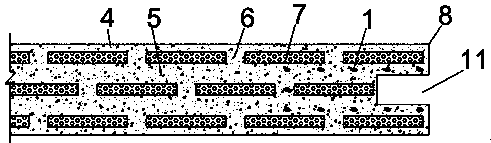

[0023] Such as figure 1 As shown, the sandwich insulation layer 7 is arranged in three rows inside and outside, the sandwich insulation layer 7 between the same row is evenly distributed, and the sandwich insulation layer 7 between different rows is staggered; the outer layer of the assembled sandwich insulation board is concrete Outer layer 4, each row of sandwich insulation layers 7 is longitudinally separated by concrete ribs 6, adjacent rows of concrete ribs 6 are staggered from each other, and the sandwich insulation layers 7 of adjacent rows are horizontally separated by concrete intermediate layers 5 . The thickness of the concrete rib 6 is set at 60mm. The sandwich insulation layer 7 adopts rigid polyurethane foam board. The thickness of the concrete outer layer 4 is set at 30mm. The thickness of the concrete interlayer 5 is set at 80mm.

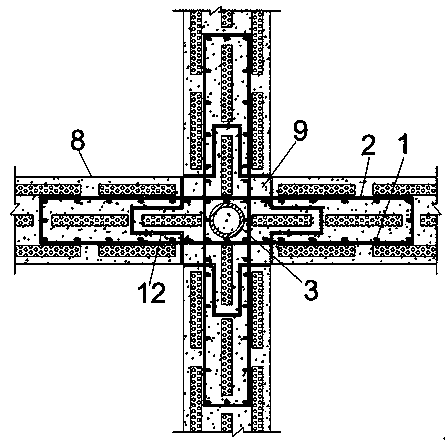

[0024] Such as Figure 2~5 As shown, the connection ends of the sub-wall panels 8 are provided with connection reinforcement l...

Embodiment 2

[0026] Such as figure 1 As shown, the sandwich insulation layer 7 is arranged in three rows inside and outside, the sandwich insulation layer 7 between the same row is evenly distributed, and the sandwich insulation layer 7 between different rows is staggered; the outer layer of the assembled sandwich insulation board is concrete Outer layer 4, each row of sandwich insulation layers 7 is longitudinally separated by concrete ribs 6, adjacent rows of concrete ribs 6 are staggered from each other, and the sandwich insulation layers 7 of adjacent rows are horizontally separated by concrete intermediate layers 5 . The thickness of the concrete rib 6 is set at 70mm. The sandwich insulation layer 7 adopts rigid polyurethane foam board. The thickness of the concrete outer layer 4 is set at 35mm. The thickness of the concrete interlayer 5 is set at 85mm.

[0027] Such as Figure 2~5 As shown, the connection ends of the sub-wall panels 8 are provided with connection reinforcement l...

Embodiment 3

[0029] Such as figure 1As shown, the sandwich insulation layer 7 is arranged in three rows inside and outside, the sandwich insulation layer 7 between the same row is evenly distributed, and the sandwich insulation layer 7 between different rows is staggered; the outer layer of the assembled sandwich insulation board is concrete Outer layer 4, each row of sandwich insulation layers 7 is longitudinally separated by concrete ribs 6, adjacent rows of concrete ribs 6 are staggered from each other, and the sandwich insulation layers 7 of adjacent rows are horizontally separated by concrete intermediate layers 5 . The thickness of the concrete rib 6 is set at 80mm. The sandwich insulation layer 7 adopts rigid polyurethane foam board. The thickness of the concrete outer layer 4 is set at 40mm. The thickness of the concrete intermediate layer 5 is set at 90mm.

[0030] Such as Figure 2~5 As shown, the connection ends of the sub-wall panels 8 are provided with connection reinforc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com