Novel welding type connecting screw pin

A welding and connecting screw technology, applied in the direction of connecting components, screws, nuts, etc., can solve the problems of complex process, easy deformation, long production cycle, etc., to ensure the strength of the pin shaft, meet the requirements of use, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

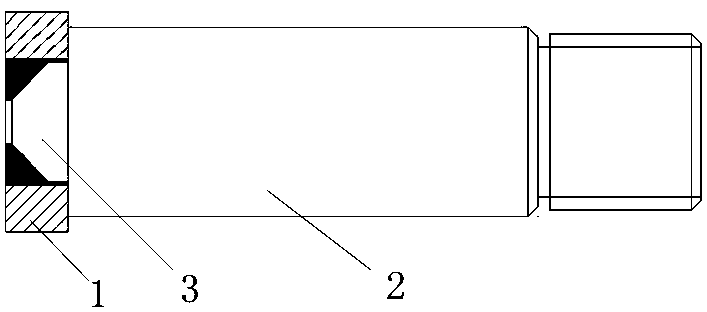

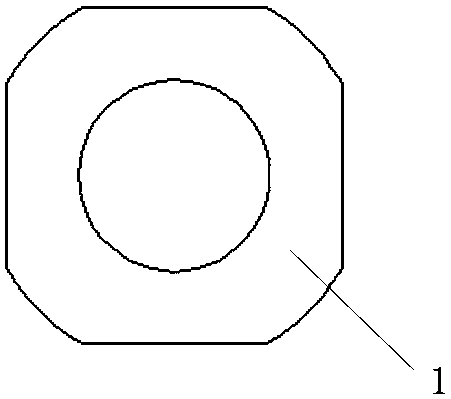

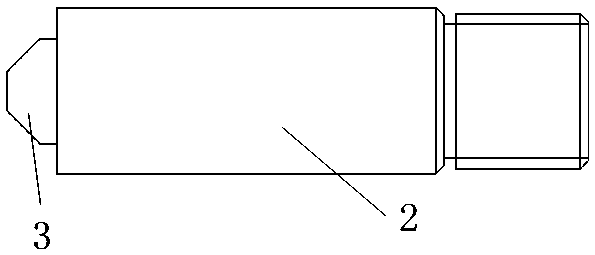

[0013] Such as Figure 1 to Figure 3 A new type of welded connecting screw pin shown is characterized in that it includes a square head 1 and a screw pin 2, and the square head 1 and the screw pin 2 are welded together.

[0014] Preferably, the square head 1 is provided with an opening 4 in the middle, and the head of the screw pin 2 is provided with an insertion section 3, and the square head 1 and the screw pin 2 are mated with the insertion section 3 through the opening 4 , The opening 4 is welded with the plug-in section 3 .

[0015] Preferably, the inserting section 3 is integrally formed with the screw pin 2 , the inserting section 3 is a circular platform with a rectangular bottom and a trapezoidal top in cross-section, and the circumference of the inserting section 3 is smaller than the diameter of the opening 4 .

[0016] Through structural optimization, the screw pin is divided into two parts: screw pin 2 and square head 1. The square head 1 and screw pin 2 are plug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com