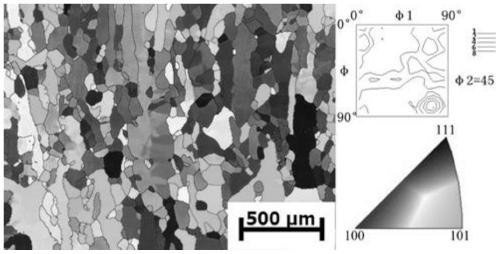

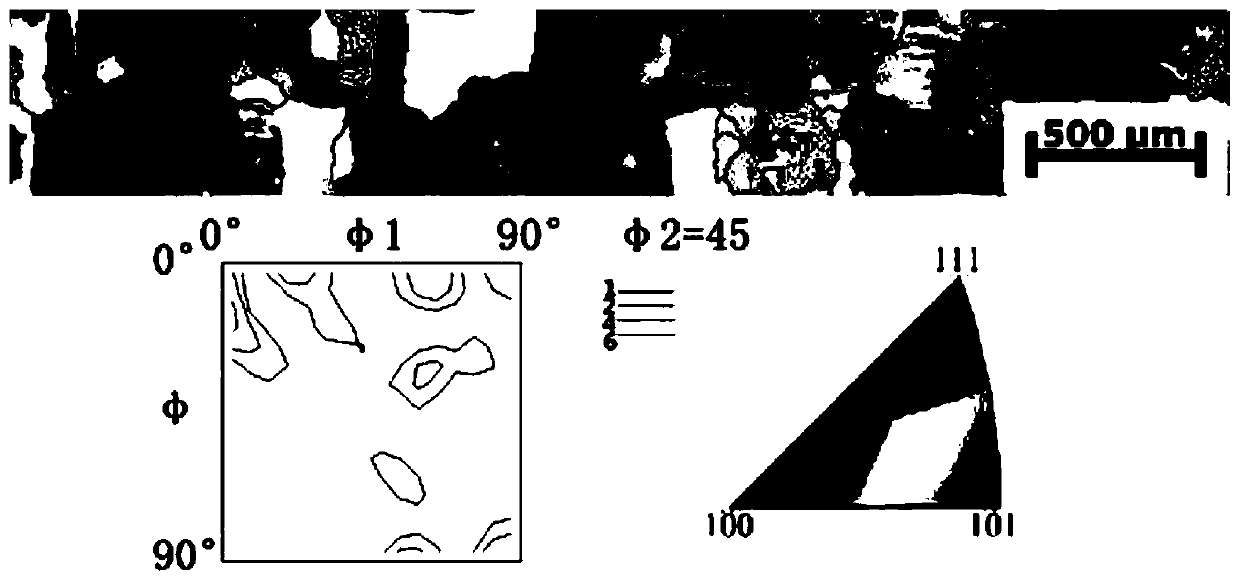

Method for preparing non-oriented electrical steel with {100} textured columnar crystal structure through original structure hot rolling method

A technology of oriented electrical steel and columnar grains, which is applied in the field of preparing {100} textured columnar grain non-oriented electrical steels by hot rolling with initial structure, can solve the problems of complicated process and damaged structure, achieve simple process, reduce iron loss, Reduce the effect of forging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing {100} textured columnar grain non-oriented electrical steel by hot rolling with initial structure, comprising the following steps:

[0028] (1) The raw material steel is smelted in a 200kg vacuum induction furnace to obtain molten steel, and then poured into a hole mold with a size of 200mm (width) × 480mm (length 1146 North America three districts (month and April) × 60mm (height), after pouring and cooling, a billet is obtained, and the billet includes the following mass percentages of C: 0.004%, Si: 0.01%, Mn: 0.58%, Al: 0.003%, S: 0.008%, P: 0.007%, the balance is iron;

[0029] (2) After milling the billet surface by 5mm along the height direction to remove scale and surface defects, wire cutting is carried out with the height direction as the normal direction of the wire cutting plane to obtain cast slabs with thicknesses of 30mm, 40mm and 50mm respectively;

[0030] (3) The hot rolling of the cast slab at 1150°C, the soaking time correspon...

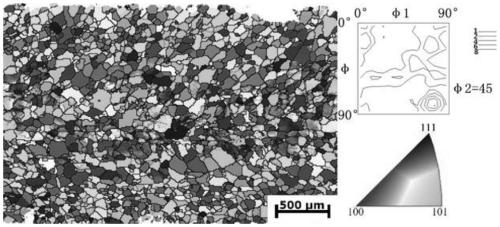

Embodiment 2

[0036] A method for preparing {100} textured columnar grain non-oriented electrical steel by hot rolling with initial structure, comprising the following steps:

[0037] (1) The raw material steel is smelted in a 200kg vacuum induction furnace to obtain molten steel, and then poured into a hole mold with a size of 200mm (width) × 480mm (length 1146 North America three districts (month and April) × 60mm (height), after pouring and cooling, a billet is obtained, and the billet includes the following mass percentages of C: 0.004%, Si: 0.01%, Mn: 0.58%, Al: 0.003%, S: 0.008%, P: 0.007%, the balance is iron;

[0038] (2) After milling the billet surface by 5mm along the height direction to remove scale and surface defects, wire cutting is carried out with the height direction as the normal direction of the wire cutting plane to obtain cast slabs with thicknesses of 30mm, 40mm and 50mm respectively;

[0039] (3) The hot rolling of the cast slab at 1150°C, the soaking time correspon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com