Two-gear output electromagnetic clutch and its control method

A technology of electromagnetic clutches and output shafts, which is applied in the direction of magnetic drive clutches, clutches, non-mechanical drive clutches, etc., can solve problems such as the inability to use hydraulic clutches, improve energy utilization, reduce electrical control components, and optimize startup characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

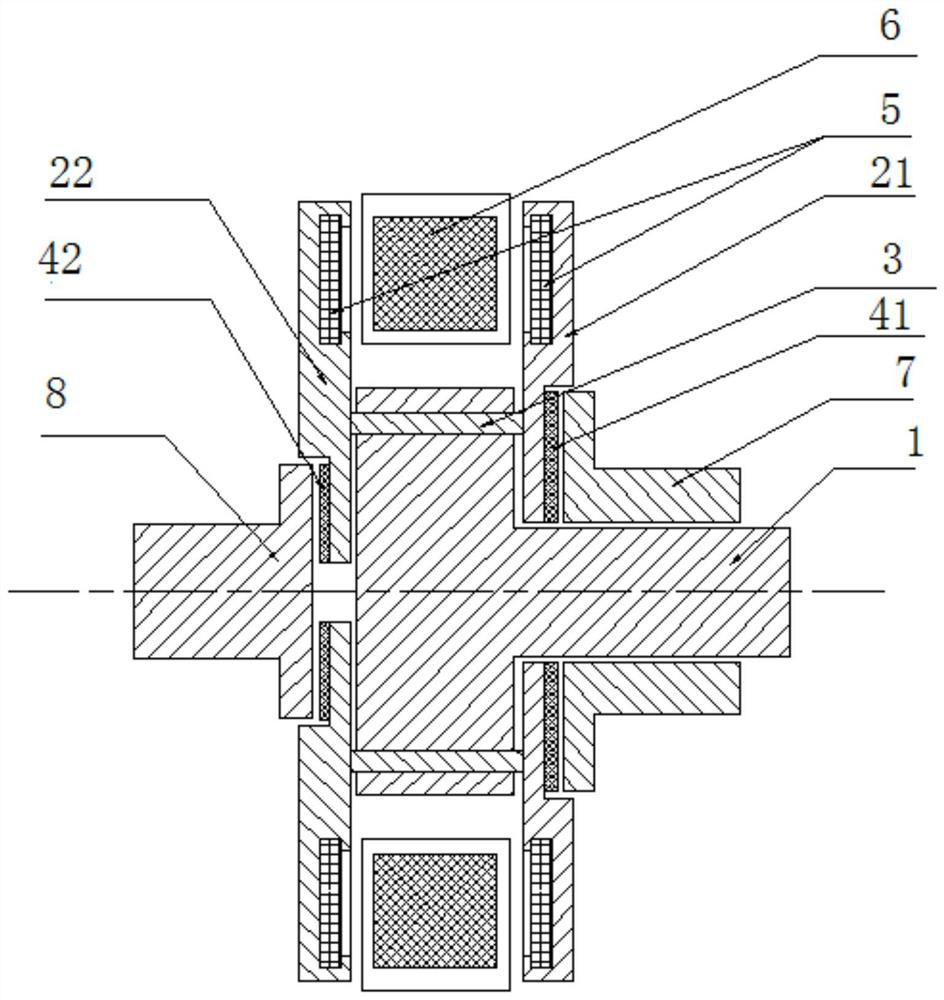

[0043] See figure 1 As shown, this embodiment is output on the same side, that is, the first output shaft 7 and the second output shaft 8 are coaxially sleeved and located on the same side of the input shaft 1 . In order to better realize the power transmission of the input shaft to the above-mentioned first output shaft and the second output shaft, the clutch member 2 in this embodiment is composed of two support plates (that is, the first support plate 21 and the second support plate 22 pass through the middle The rods 23 are connected, that is, the middle rod 23 is fixed between the first support plate 21 and the second support plate 22 .

[0044] In this embodiment, the clutch member 2 formed by two support plates is convenient for installing the above-mentioned electromagnetic clutch assembly. There is a certain interval between the first support plate 21 and the second support plate 22. The coil assembly 6 can be placed in the circumferential groove between the first su...

Embodiment 2

[0050] like figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the first output shaft 7 and the second output shaft 8 are arranged on opposite sides, that is, the power is output on both sides. In this embodiment, the first output shaft 7 and the input shaft 1 are sleeved coaxially, and the second output shaft 8 is arranged opposite to the input shaft 1 and the first output shaft 7 .

[0051] The structure of the clutch 2 in this embodiment is the same as that of the clutch 2 in Embodiment 1, and it consists of two support plates (i.e. the first support plate 21 and the second support plate 22) connected by an intermediate rod. In the example, the first output shaft 7 and the input shaft 1 are coaxially sleeved, the end of the input shaft 1 is located between the two support plates, and the middle rod between the two support plates is passed through the connection at the end of the input shaft. On the disk, that is, the middle rod is used as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com