Heat pipe structure for achieving dropwise condensation

A drop-shaped condensation and heat pipe technology is applied in the field of heat pipes to achieve the effects of easy implementation, enhanced heat transfer efficiency and simple processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

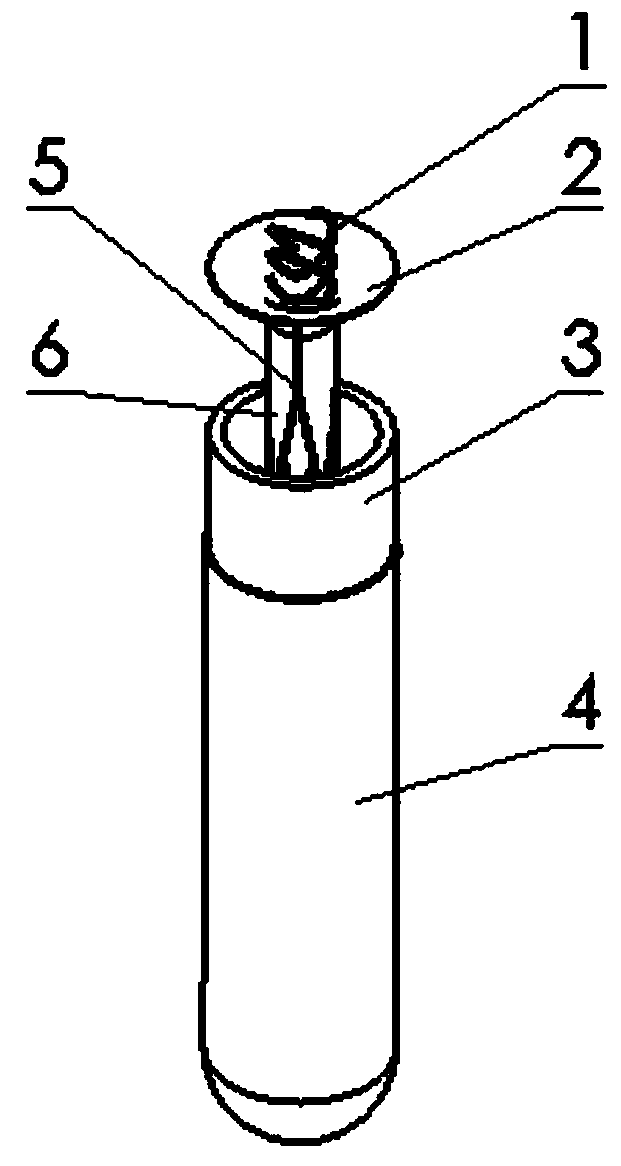

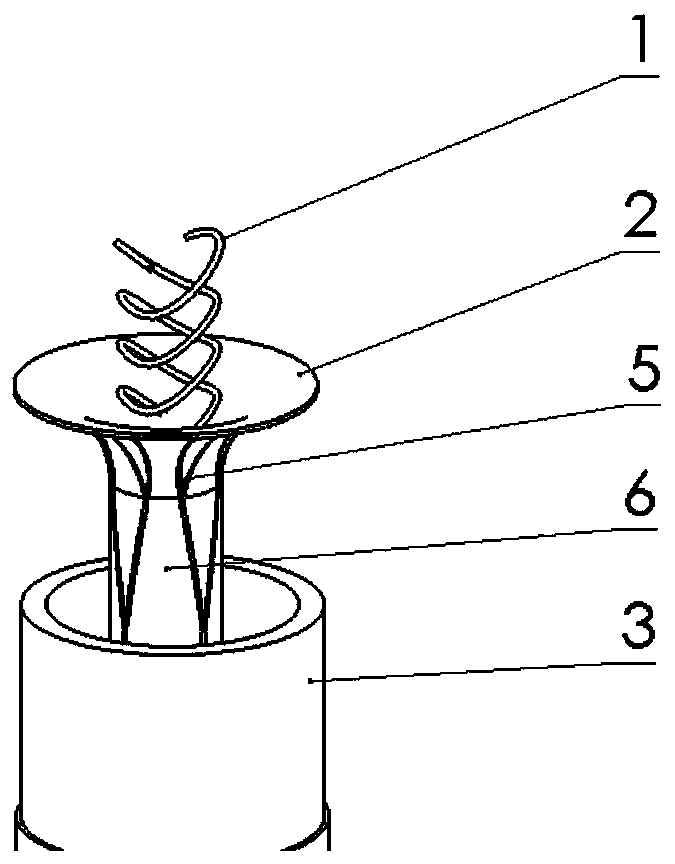

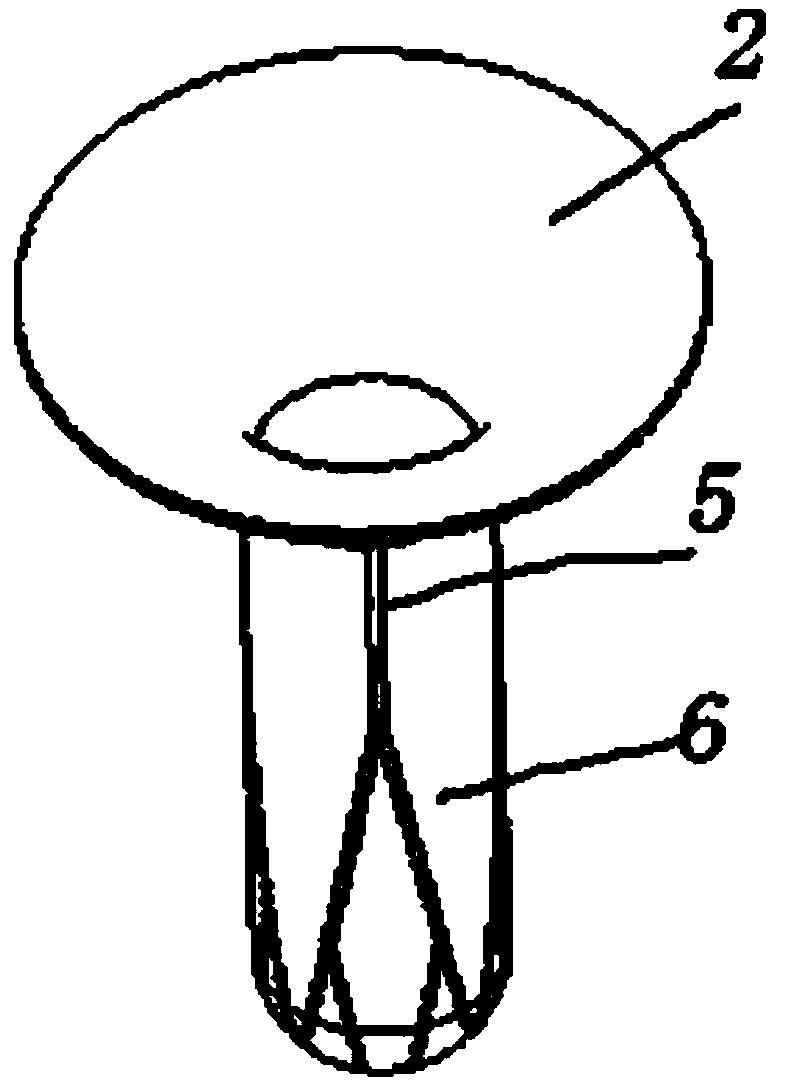

[0028] Embodiment 1: as Figure 1-Figure 7 As shown, a heat pipe structure that realizes droplet condensation, the heat pipe is divided into three sections, that is, the evaporation section, the heat insulation section and the condensation section, including an outer tube 4 with an open upper end and a sealed lower end, a liquid-absorbing core 3, and an open upper end with a lower end. The sealed inner tube 2 and the cooling device 1, the liquid-absorbing core 3 is arranged on the inner wall of the outer tube 4, the inner tube 2 is inserted into the outer tube 4 and the upper end is sealed with the outer tube 4, the inner liquid-absorbing core 3 and the outer surface of the inner tube 2 The gap to keep the steam flowing. The outer surface of the inner tube is the drop-like condensation surface of spider silk. It is made based on the structure and principle of water-absorbing spider silk. The gap is the radial distance between the liquid-absorbing core and the inner tube, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com