Method and device for dynamically measuring dam break evolution process

An evolutionary and dynamic measurement technology, applied in measurement devices, fluid dynamics tests, and testing of machine/structural components, etc., which can solve problems such as the size of the test model, the small size, and the large difference between the model and the prototype stress level. , to achieve the effect of high cost, time-consuming and high risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for dynamically measuring the evolution process of a dam failure, comprising the following steps:

[0044] S1. Start the motor 10 on the device for dynamically measuring the dam break evolution process, drive the ultrasonic ranging mechanism to run up and down through the transmission mechanism, and drive the gridded laser point measuring mechanism to move back and forth;

[0045] S2. Start the external supergravity field providing device to drive the dynamic measurement of the dam break evolution process device to operate under the supergravity field, and control the water flow into the dynamic measurement dam break evolution process device through the external control system;

[0046] S3, measure the flow Q in real time through the rectangular water measuring weir 4 installed inside the dynamic measurement dam break evolution process device;

[0047] S4. Use the ultrasonic ranging mechanism to measure the change of the water head H in front of the rectangular...

Embodiment 2

[0056] Embodiment 2: the difference based on Embodiment 1 is;

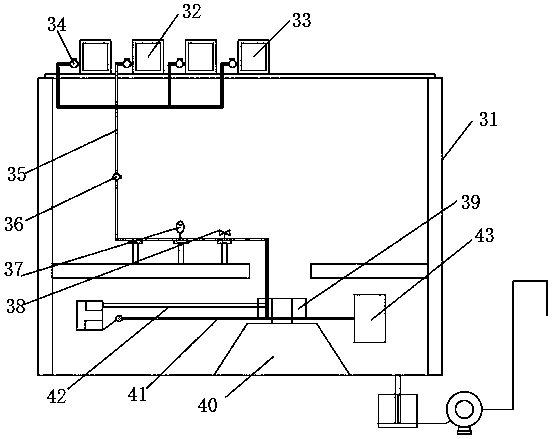

[0057] A device for dynamically measuring the evolution process of a dam failure, applied to a method for dynamically measuring the evolution process of a dam failure, comprising: a main frame 31, an automatic water flow control mechanism, and a centrifugal model test mechanism for a dam failure;

[0058] An automatic water flow control mechanism, the automatic water flow control mechanism is placed in the main frame 31, and the automatic water flow control mechanism is connected with the dam failure centrifugal model test mechanism;

[0059] The special model box for dam break test, the special model box for dam break test is placed under the left side inside the main frame 31, and the special model box for dam break test is connected with the automatic water flow control mechanism.

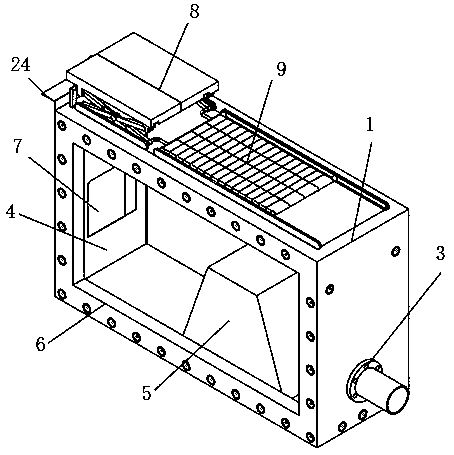

[0060] The special model box for dam break test includes: box body 1, high-strength inner screw sleeve 2, connecting flange 3, rec...

Embodiment 3

[0062] Embodiment 3: the difference based on embodiment 1 and 2 is;

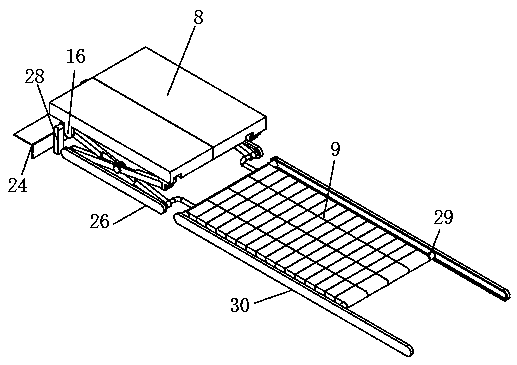

[0063] The transmission mechanism includes: motor 10, transmission gear 11, rotating gear 12, rotating shaft 13, limit gear 14, rotating half gear 15, rotating rod 17, transmission rod 18, fixed shaft 19, connecting shaft 23, mounting plate 24, limiting Position shaft 25, limit housing 26, movable shaft 27 and stabilizing column 28, a mounting plate 24 is fixedly installed on the left side of the upper end of the box body 1, a motor 10 is fixedly installed in the middle of the mounting plate 24, the front end of the main shaft of the motor 10 and the shaft center of the transmission gear 11 Fixed connection, the transmission gear 11 is meshed with the rotating gear 12, the axis of the rotating gear 12 is fixedly connected with the middle part of the rotating shaft 13, and the inner side of the left and right ends of the rotating shaft 13 is fixedly connected with the axis of the limit gear 14, and the limit g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com