Shed frame test method in pilot tunnel digging technology

A test method and scaffolding technology, which are applied in the testing of mechanical parts, the testing of machine/structural parts, and the use of stable tension/pressure to test the strength of materials, etc. problems such as unpredictable frame damage, to achieve the effect of providing safety and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

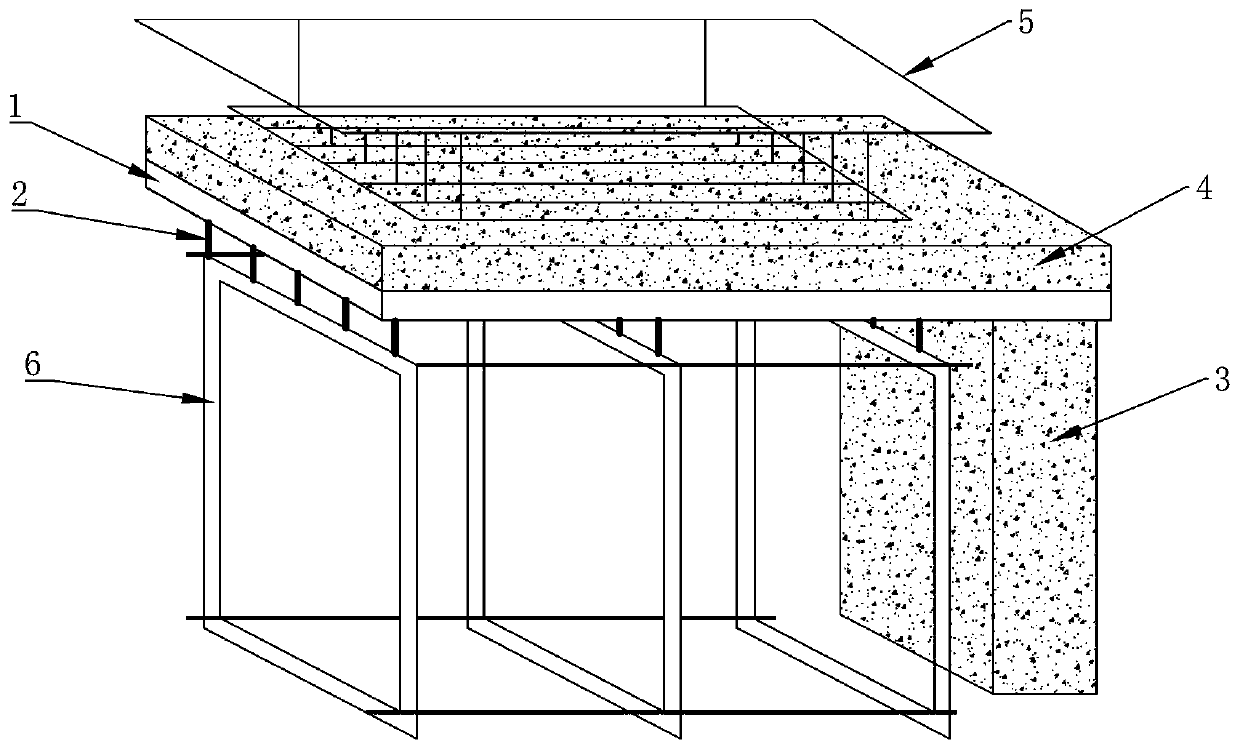

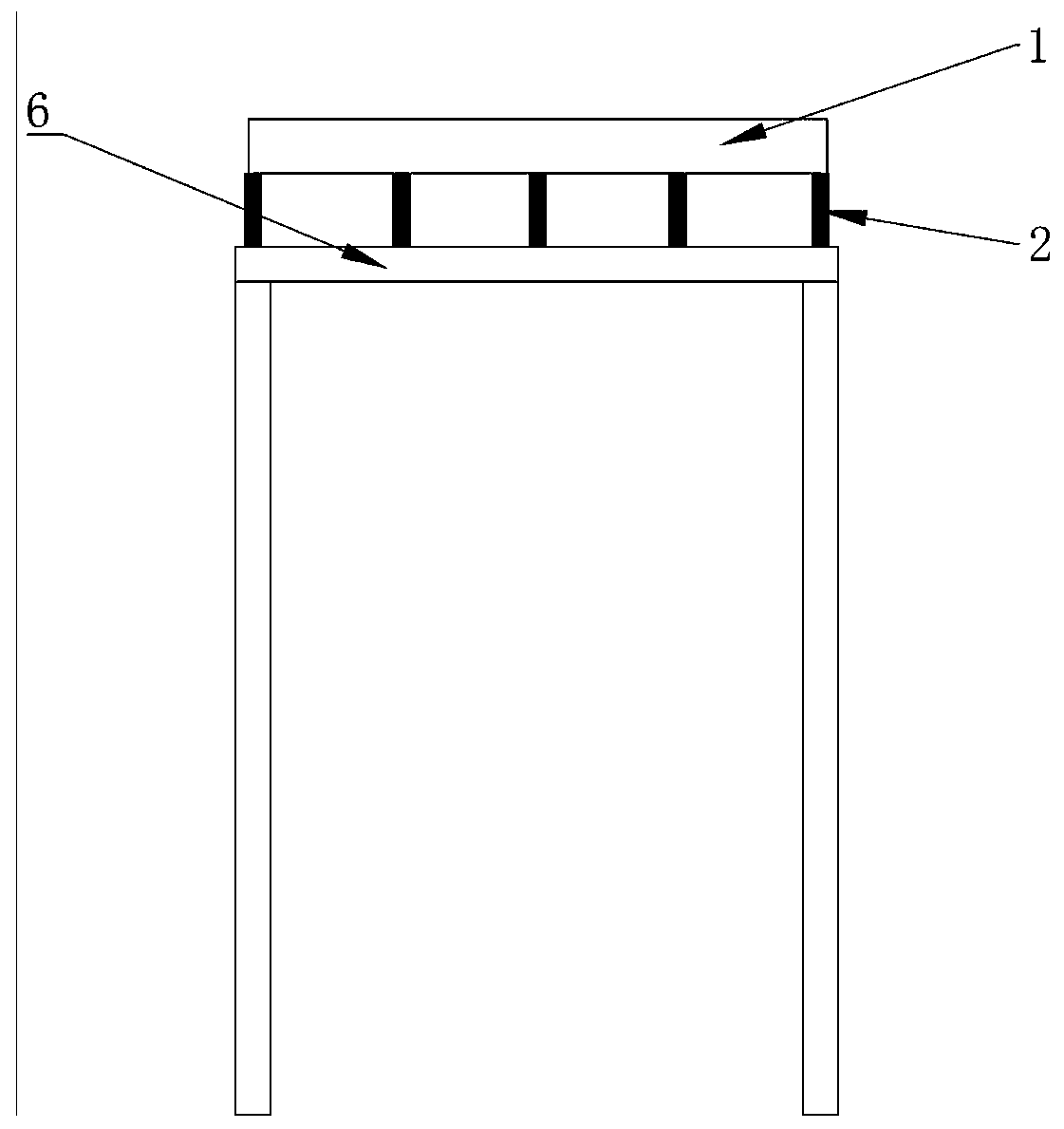

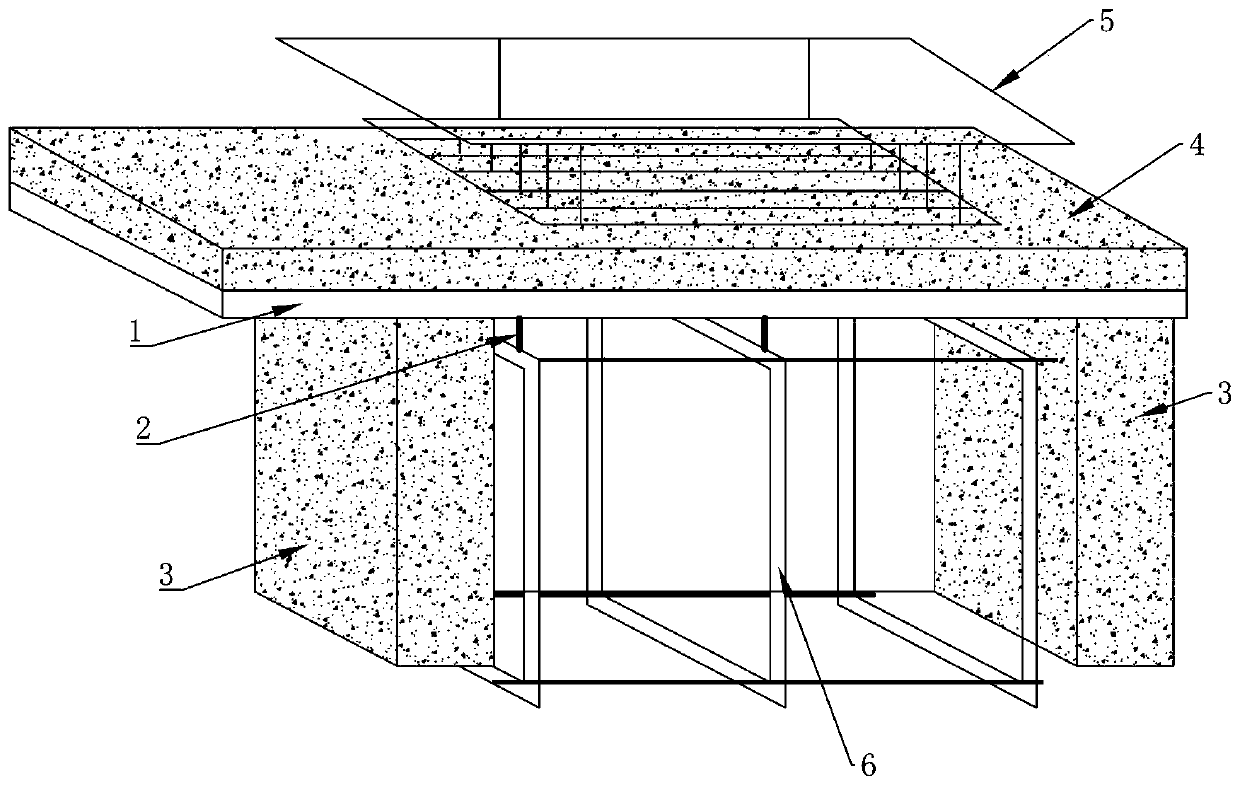

[0031] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0032] During the excavation of the pilot tunnel, the top scaffolding is firstly used to support the top of the cave body to prevent construction accidents such as collapse. The top scaffolding needs to meet the structural requirements such as strength and rigidity to achieve the supporting function. However, at present, most of the structural strength of the scaffolding is obtained through structural calculation or construction experience. There is no test and verification process for the actual stress state of the scaffolding, and there may be waste of scaffolding structural strength or the scaffolding structure cannot meet the requirements. Support stability requirement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com