A method for detecting magnetic properties of pipeline steel

A detection method and technology for pipeline steel, which are applied in the measurement of magnetic properties, the use of stable tension/pressure to test the strength of materials, and the measurement device, which can solve the problems of no pipeline steel magnetic effect and application research.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0020] A specific embodiment of the present invention: a method for detecting magnetic properties of pipeline steel,

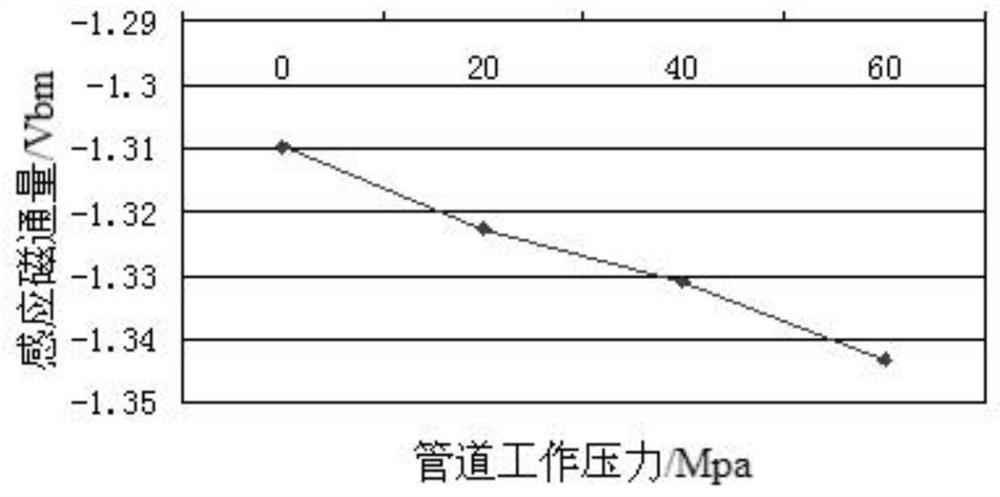

[0021] Step 1: Design samples: Select 4 groups of X80 pipeline steel round bar samples of different production batches, each group is cut into five pieces, which are used for microstructure electron microscope scanning, hysteresis curve determination, magnetization parameter determination, magnetic flux-tensile stress Test, magnetic flux-compressive stress test and other five test conditions, select pipeline steel round bar samples with different wall thicknesses and different diameters to verify the influence of wall thickness and pipe diameter on the incremental change law of induced magnetic flux under different working pressures;

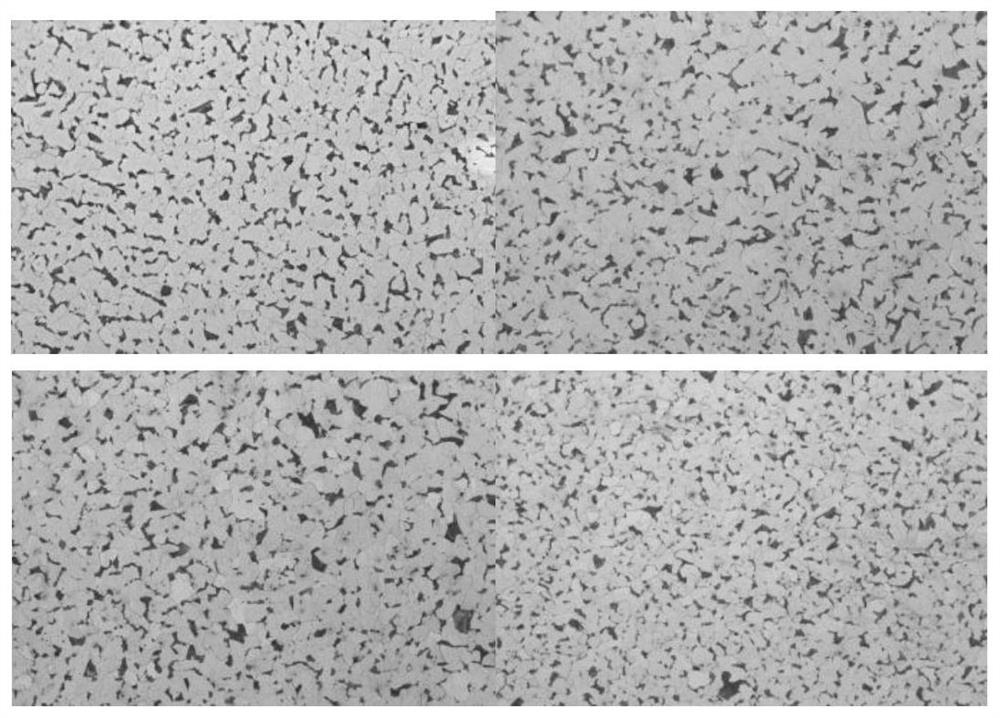

[0022] Step 2: Observation of microstructure: Leica DMI3000M / DFC450 inverted metallographic microscope was used to analyze the microstructure of the test sample under the condition of magnification of 200 times. The structure dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com