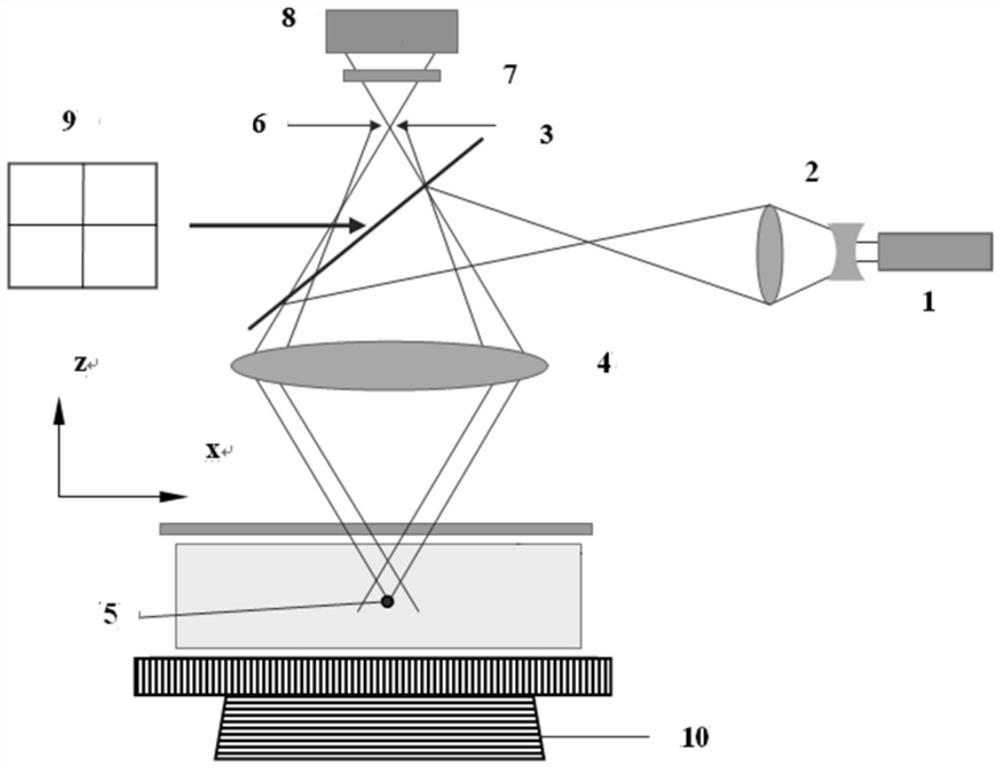

Non-destructive measurement method of side wall angle of micro-nano scale dielectric waveguide or step structure by using confocal laser scanning microscope system

A laser scanning and microscopic system technology, which is applied in the field of precision processing and precise measurement of micro-nano optical media devices and structures, can solve the problem of inability to obtain measurement values of sidewall angles, etc., achieves easy handling and placement, small size, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

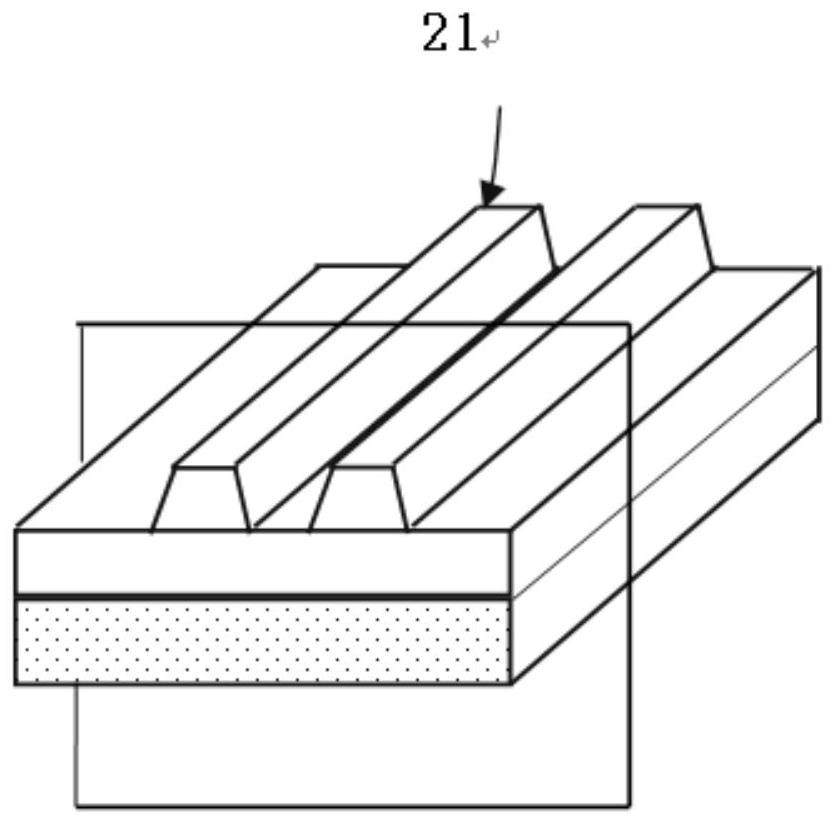

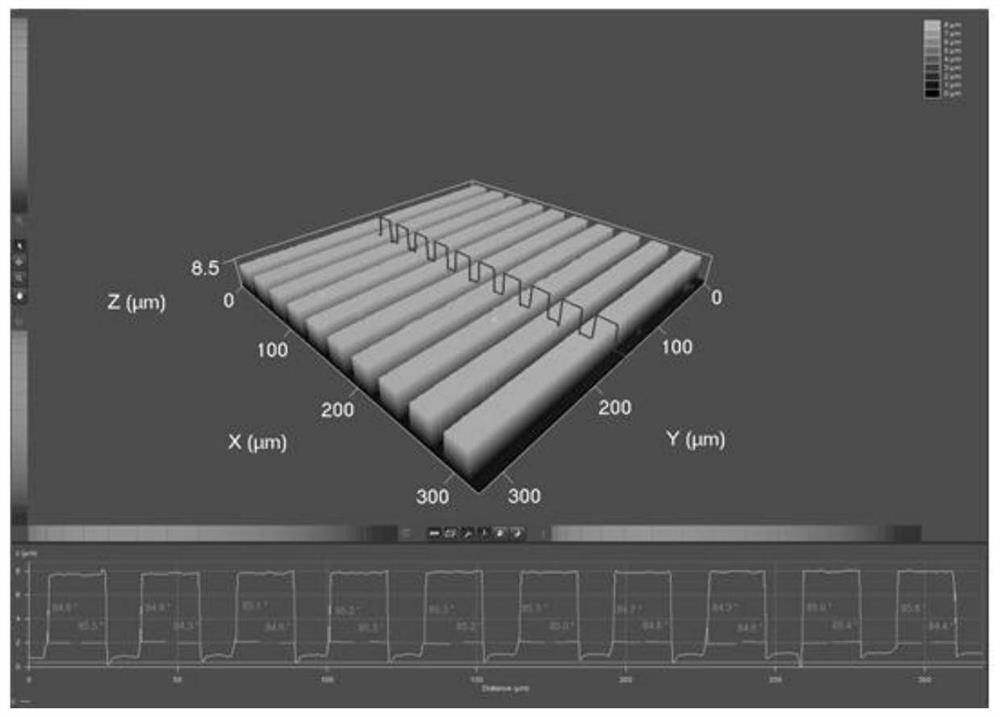

[0053] Example 1: For such as Figure 7 A reconstructed scan pattern shown in the same waveguide, select a different position to make the side corner 21 value after the cutting section, and then the average value of all selected locations is φ. ave And standard utilization value. Then using Figure 6 The measured intrinsic error is obtained. Figure 7 B The average value shown is compensated to obtain the final value. From Figure 5 B can be seen, the average of the left and right side corners φ ave From 84.90 ° and 84.83 °, respectively, by Figure 4 The given measurement error corresponds to the two angles values to -1.93 ° and -1.97 °, respectively, such that the left and right sides of the measured waveguide structure are: 84.90 ° - (- 1.93 °) = 86.83 ° and 84.83 ° - (-1.97 °) = 86.80 °.

Embodiment 2

[0054] Example 2: Scanning graphics for rebuilding, such as Figure 8 A, select a plurality of waveguide channels, select one position to make the side corner 21 value after cutting the cutting section, and then evaluate all waveguide channels or structures φ ave And standard utilization value. Then using Figure 4 The measured intrinsic error is obtained. Figure 8 B The average value shown in B ave Compensation and get the final value. From Figure 8 B can be seen, the average of the left and right side corners φ ave 85.00 ° and 84.90 °, respectively, by Figure 6 The given measurement error corresponds to the two angles values to -1.90 ° and -1.93 °, respectively, such that the left and right sides of the measured waveguide structure are: 85.00 ° - (- 1.90 °) = 86.90 ° and 84.90 ° - (-1.93 °) = 86.83 °.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com