Formaldehyde gas sensor based on Ga doped In2O3 nanometer sensitive material with three-dimensional inverse opal structure and preparation method thereof

A technology of inverse opal structure and sensitive material, applied in the field of highly sensitive formaldehyde gas sensor and its preparation, can solve the problems of insufficient discharge of formaldehyde pollutants, insufficient indoor ventilation rate, etc. Active site, the effect of improving the utilization efficiency of sensitive body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

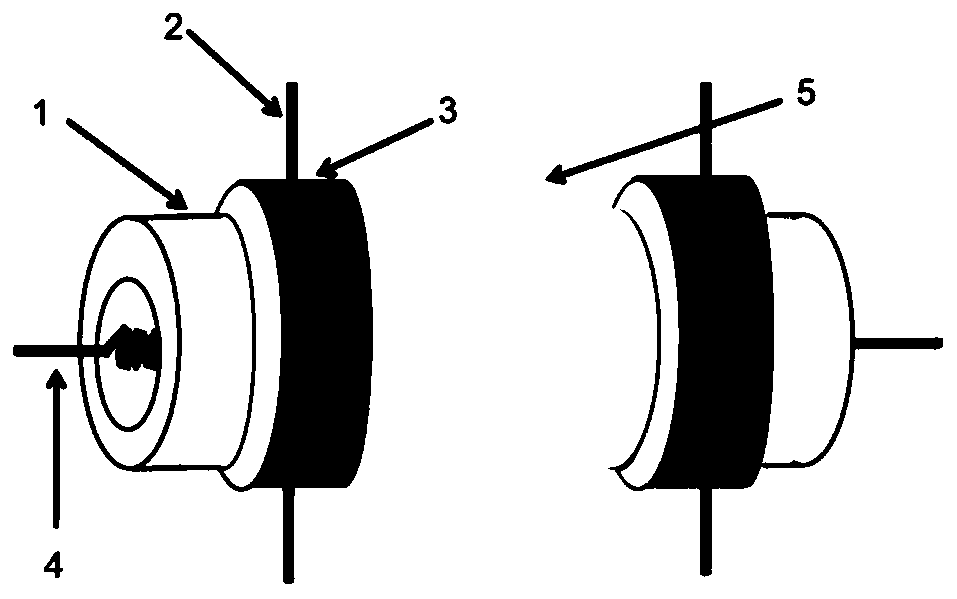

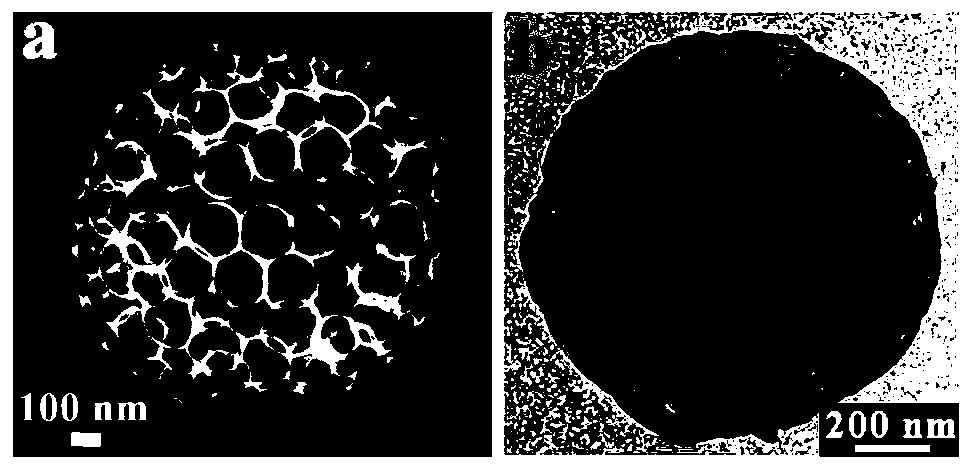

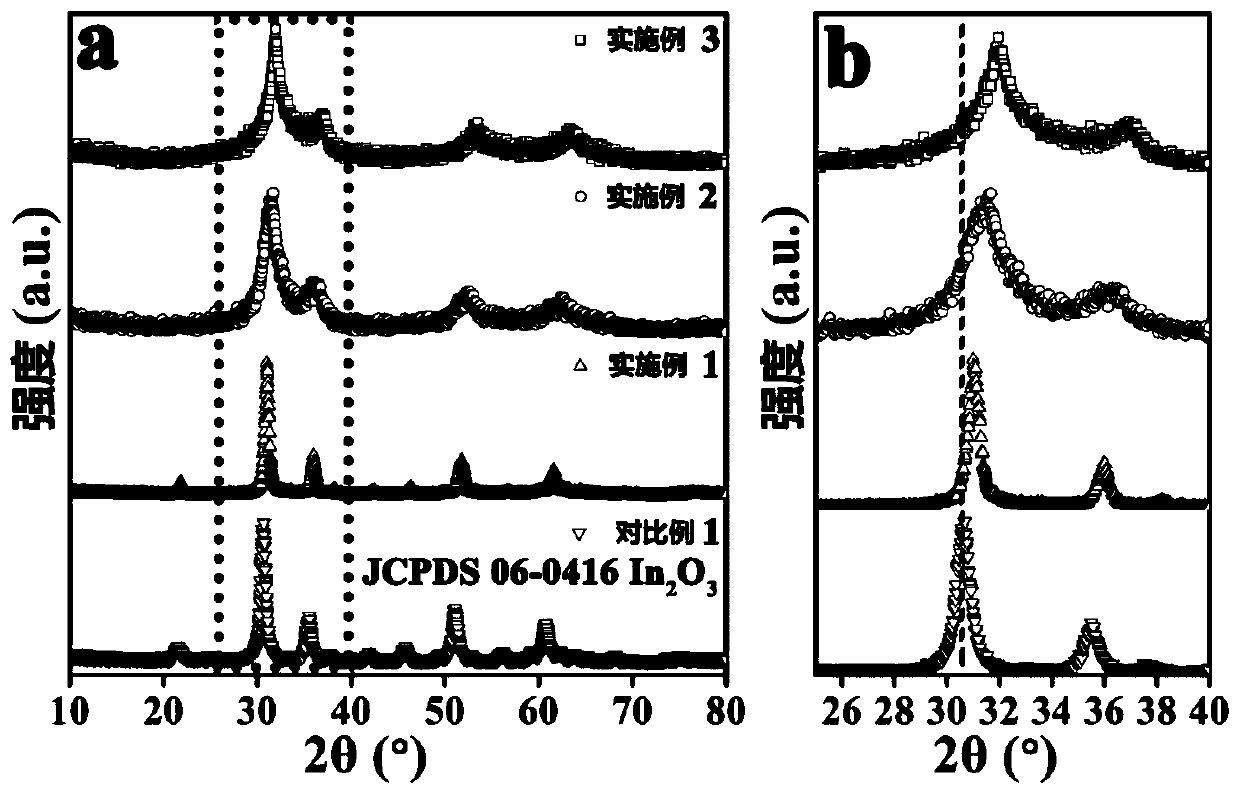

[0051] Ga-doped three-dimensional inverse opal structure In 2 o 3 Microspheres are used as nano-sensitive materials to make formaldehyde gas sensors. The specific manufacturing process is as follows:

[0052] (1) First, add 0.3 g of sodium polystyrene sulfonate, 0.25 g of sodium bicarbonate, and 30 mL of styrene into 300 mL of deionized water in sequence, and heat in a water bath under a nitrogen atmosphere (nitrogen flow rate: 30 sccm) (water bath heating temperature : 70°C) stirring. After stirring for 1 hour, add 0.15 g of potassium persulfate, and continue stirring in a water bath (water bath heating temperature: 70°C) under a nitrogen atmosphere (nitrogen flow rate: 30 sccm) for 18 hours;

[0053] (2) After the reaction is finished, the obtained product is alternately centrifuged and washed with water and ethanol, and the obtained product is dried to obtain polystyrene microsphere powder;

[0054] (3) Add 10 g of polystyrene microsphere powder obtained in step (2) into...

Embodiment 2

[0061] Ga-doped three-dimensional inverse opal structure In 2 o 3 Microspheres are used as nano-sensitive materials to make formaldehyde gas sensors. The specific manufacturing process is as follows:

[0062] (1) First, add 0.3 g of sodium polystyrene sulfonate, 0.25 g of sodium bicarbonate, and 30 mL of styrene into 300 mL of deionized water in sequence, and heat in a water bath under a nitrogen atmosphere (nitrogen flow rate: 30 sccm) (water bath heating temperature : 70°C) stirring. After stirring for 1 hour, add 0.15 g of potassium persulfate, and continue stirring in a water bath (water bath heating temperature: 70°C) under a nitrogen atmosphere (nitrogen flow rate: 30 sccm) for 18 hours;

[0063] (2) After the reaction is finished, the obtained product is alternately centrifuged and washed with water and ethanol, and the obtained product is dried to obtain polystyrene microsphere powder;

[0064] (3) Add 10 g of polystyrene microsphere powder obtained in step (2) into...

Embodiment 3

[0071] Ga-doped three-dimensional inverse opal structure In 2 o 3 Microspheres are used as sensitive materials to make formaldehyde gas sensors. The specific manufacturing process is as follows:

[0072] (1) First, add 0.3 g of sodium polystyrene sulfonate, 0.25 g of sodium bicarbonate, and 30 mL of styrene into 300 mL of deionized water in sequence, and heat in a water bath under a nitrogen atmosphere (nitrogen flow rate: 30 sccm) (water bath heating temperature : 70°C) stirring. After stirring for 1 hour, add 0.15 g of potassium persulfate, and continue stirring in a water bath (water bath heating temperature: 70°C) under a nitrogen atmosphere (nitrogen flow rate: 30 sccm) for 18 hours;

[0073] (2) After the reaction is finished, the obtained product is alternately centrifuged and washed with water and ethanol, and the obtained product is dried to obtain polystyrene microsphere powder;

[0074] (3) Add 10 g of polystyrene microsphere powder obtained in step (2) into 40 m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap