Large-size rectangular reflection lens clamping device

A clamping device, large-scale technology, applied in installation, optics, instruments, etc., can solve the problems of easy damage to the surface coating of the reflector, difficult operation, and complicated disassembly and assembly of large-size rectangular reflectors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

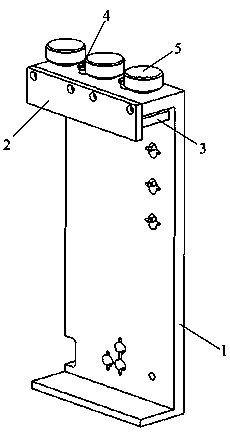

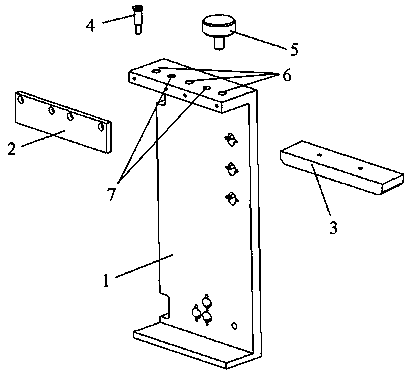

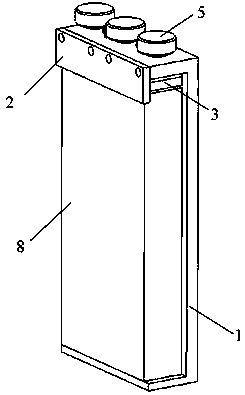

[0026] The large-size rectangular mirror clamping device of the present invention will be described in detail below in conjunction with the drawings and embodiments of the specification:

[0027] Such as Figure 1~3 as shown,

[0028] A clamping device for a large-sized rectangular reflector, comprising a base 1 and a front baffle 2 connected to the front end of the upper horizontal plate of the base 1, a pressing piece 3 is arranged under the upper horizontal plate of the base 1, and the pressing piece 3 is connected to the base 1 The upper horizontal plates are connected by bolts 4; a plurality of threaded holes 6 and through holes 7 are evenly distributed on the upper transverse plate of the base body 1, and the threaded holes 6 and through holes 7 are arranged at intervals; the adjusting knob 5 is screwed into the threaded holes 6 , and its bottom end touches the pressing piece 3.

[0029] The base 1 is composed of a vertical plate and an upper horizontal plate and a low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com