Photoelectric tracking system control method based on differential tracker

A technology of photoelectric tracking system and differential tracker, which is applied in the direction of electric controllers and controllers with specific characteristics, can solve the problems of weighting and control strategies that are difficult to meet high-performance control, and achieve simplified controller design, clear thinking, and The effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with the accompanying drawings and the photoelectric tracking experimental platform as an example, the specific implementation mode, process and effect of the present invention will be described in detail:

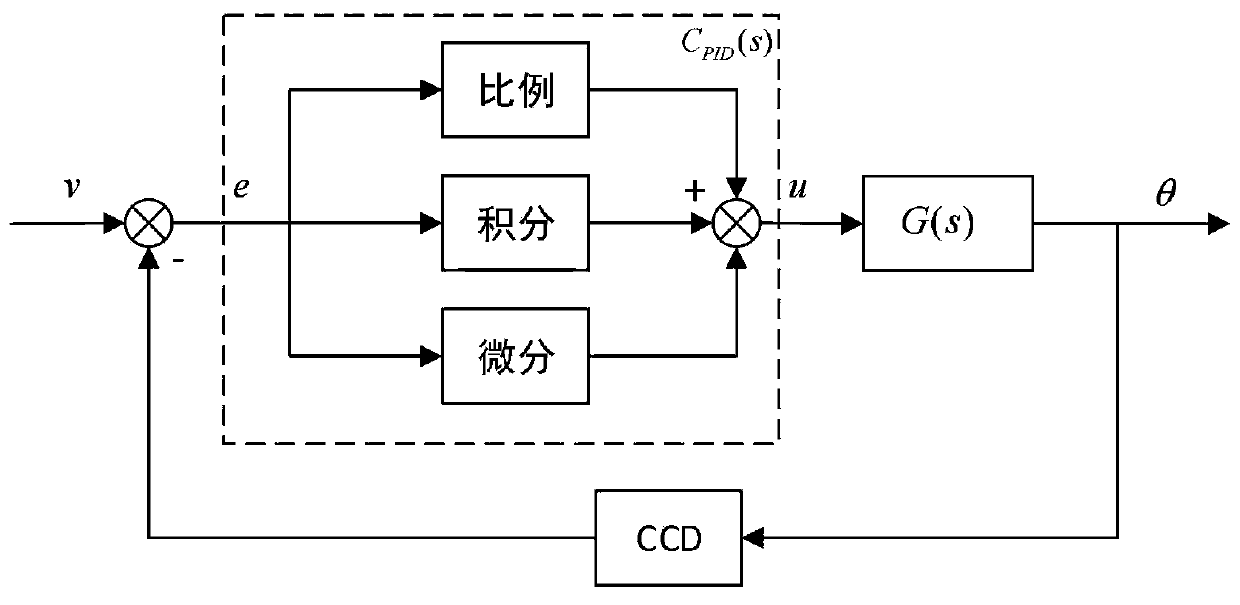

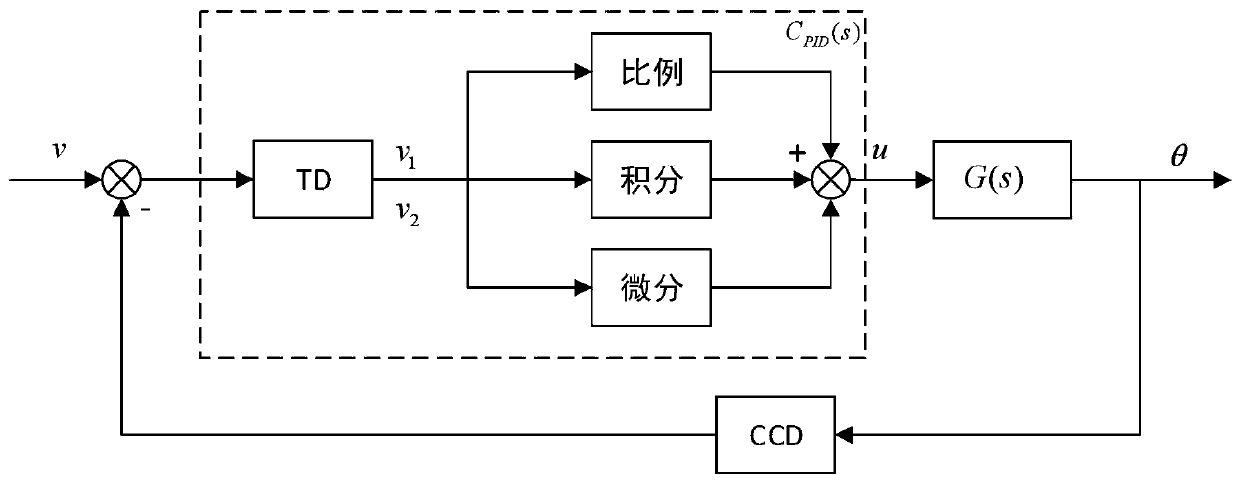

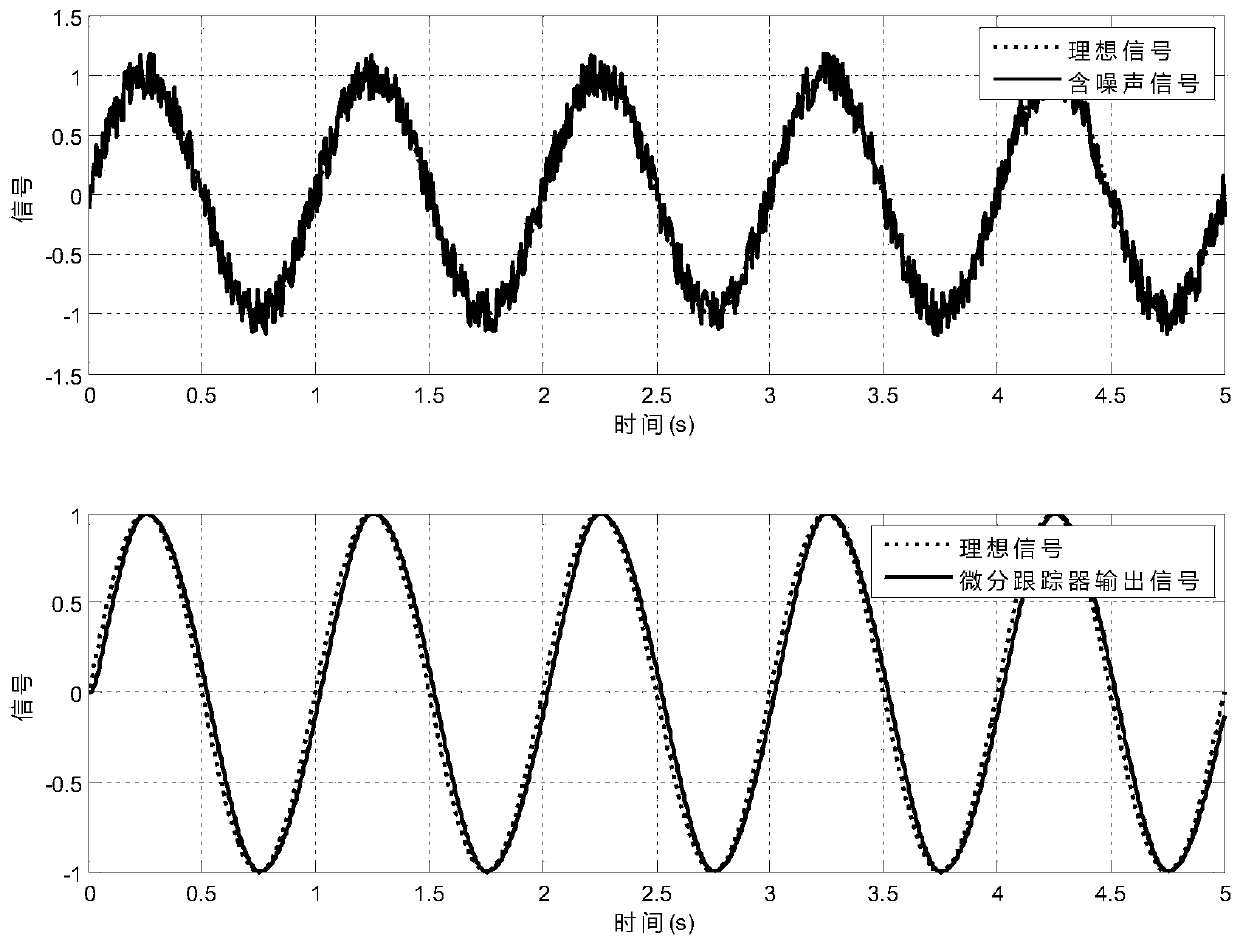

[0030] Such as figure 1 The block diagram of the traditional PID controller is shown. Its control principle is to eliminate errors based on errors, and control the closed-loop stability of the controlled system by weighting the past, present and change trends of errors. However, it is difficult to meet the high-performance control requirements. When a discontinuous or random noise measurement signal is used to extract a continuous signal and its differential signal, since the differentiator cannot be physically realized, it can only be approximated, but when the input signal is polluted by noise, the approximate differential signal in the output will be amplified In the meantime, in order to reduce the overshoot, mechanism wear and unnecessary e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com